20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

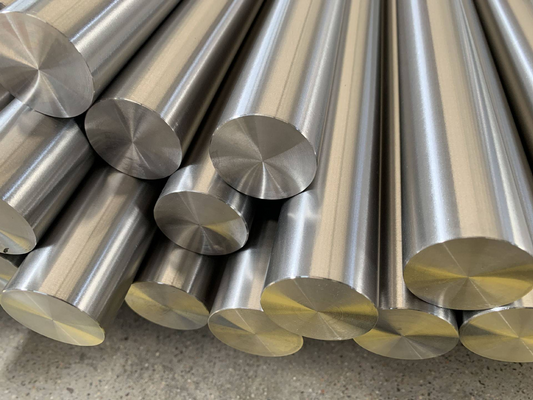

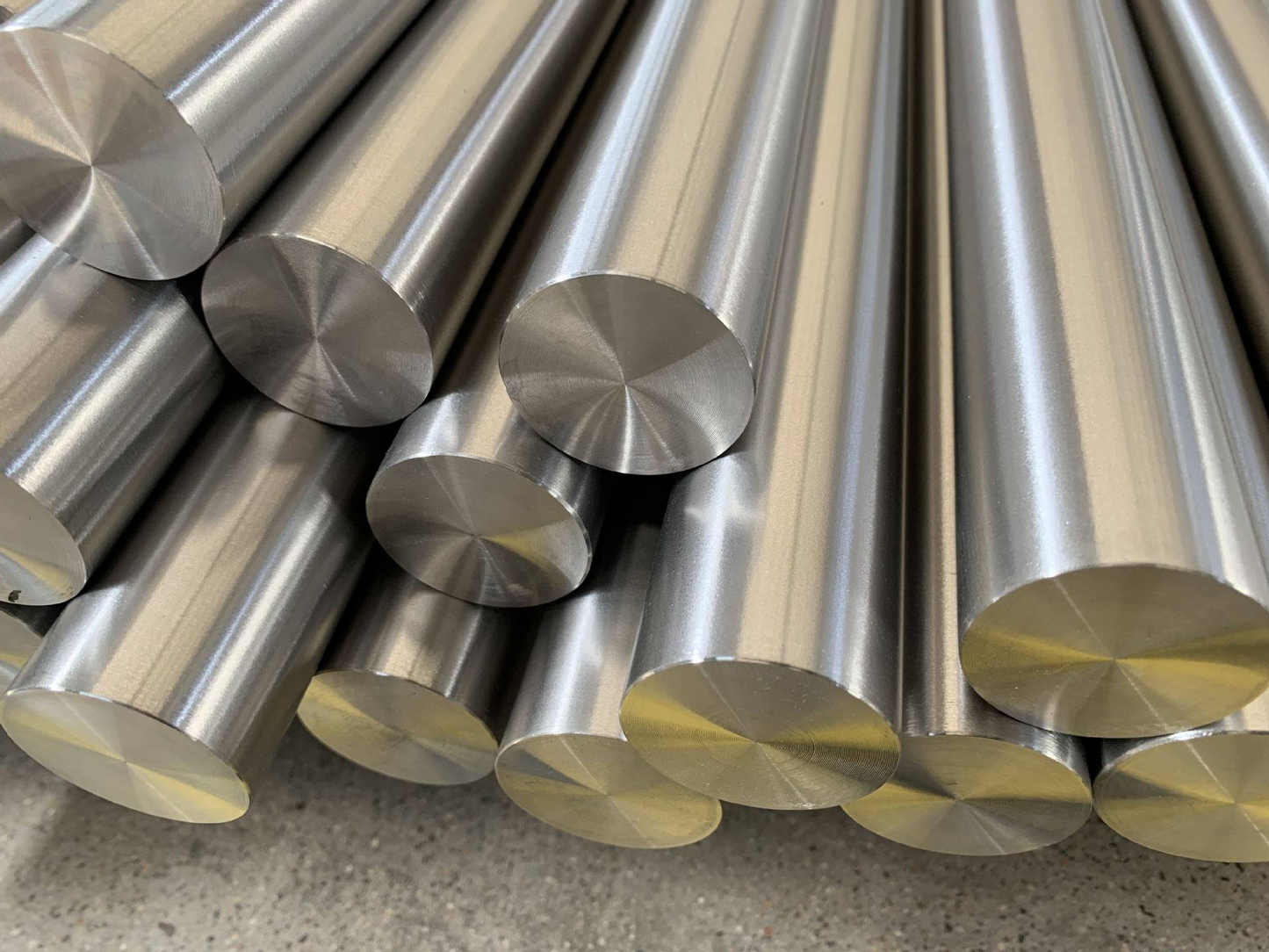

Product Overview

Características Metalúrgicas

O aço EN31 exibe uma microestrutura martensítica após a têmpera, com carbonetos de cromo uniformemente distribuídos que proporcionam resistência ao desgaste excepcional e estabilidade dimensional. O alto teor de carbono permite uma capacidade de têmpera profunda, enquanto a adição de cromo melhora a temperabilidade e a resistência à corrosão. A morfologia controlada de carbonetos da MetalZenith garante um equilíbrio ideal entre dureza e tenacidade para aplicações estruturais.

Processo de Tratamento Térmico

A MetalZenith emprega ciclos de tratamento térmico precisos, incluindo recozimento esferoidizante a 750-780°C para melhorar a usinabilidade, seguido de têmpera a 820-860°C com resfriamento controlado em óleo ou banhos de sal. O revenimento a 150-200°C alcança a retenção ideal de dureza enquanto alivia tensões internas. Nossos fornos controlados por computador garantem aquecimento uniforme e controle preciso de temperatura durante todo o processo.

Excelência na Fabricação

Nosso avançado processo de fabricação incorpora desgasificação a vácuo para minimizar o teor de hidrogênio e a formação de inclusões. Operações de forjamento e laminação controladas otimizam o fluxo de grãos e eliminam defeitos internos. Os sistemas de qualidade da MetalZenith incluem testes ultrassônicos 100% e inspeção por partículas magnéticas para garantir a integridade estrutural para aplicações críticas.

Testes de Qualidade Especializados

O aço EN31 passa por testes abrangentes, incluindo testes de fadiga em feixe rotativo para avaliar limites de resistência, análise de estabilidade dimensional sob ciclagem térmica e testes especializados de vida útil de rolamentos. Nossos laboratórios realizam estudos minuciosos de temperabilidade, medições de tensões residuais e análises microestruturais para garantir desempenho consistente em ambientes estruturais exigentes.

Aplicações de Engenharia

Para aplicações de fabricação mecânica, o EN31 proporciona resistência ao desgaste excepcional em sistemas de rolamento de alta carga e componentes de máquinas de precisão. Na fabricação de veículos, sua superior resistência à fadiga o torna ideal para componentes de transmissão e elementos de suspensão. A estabilidade dimensional e a retenção de dureza do aço garantem desempenho confiável em aplicações de engenharia geral que exigem longa vida útil e manutenção mínima.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.95 - 1.10 |

| Cromo (Cr) | 1.30 - 1.60 |

| Manganês (Mn) | 0.25 - 0.45 |

| Silício (Si) | 0.15 - 0.35 |

| Fósforo (P) | ≤ 0.025 |

| Enxofre (S) | ≤ 0.025 |

| Níquel (Ni) | ≤ 0.30 |

| Cobre (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (MPa) | ≥ 1900 |

| Resistência à Tração (MPa) | 2100 - 2400 |

| Alongamento (%) | ≥ 8 |

| Energia de Impacto a 20°C (J) | ≥ 15 |

| Dureza (HRC) | 60 - 67 |

| Resistência à Fadiga (MPa) | ≥ 900 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade (g/cm3) | 7.81 |

| Ponto de Fusão (°C) | 1420 - 1460 |

| Condutividade Térmica (W/m·K) | 42.7 |

| Expansão Térmica (×10??/K) | 12.3 |

| Módulo de Elasticidade (GPa) | 210 |

| Razão de Poisson | 0.27 - 0.30 |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Barras, Varas, Tubos, Forjados, Estoque de Precisão |

| Faixa de Diâmetro | 10 - 300mm |

| Faixa de Comprimento | 1000 - 6000mm |

| Acabamento de Superfície | Laminação a Quente, Laminação a Frio, Moagem, Polido |

| Conformidade com Normas | ASTM A295, ISO 683-17, EN 10084, JIS G4805 |

| Condição de Tratamento Térmico | Recozido, Endurecido & Temperado, Esferoidizado |

| Classe de Tolerância | h9, h11 (Laminado a Frio), ±0.5mm (Laminado a Quente) |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing Aço EN31 (52100)

Tecnologia Avançada de Fusão a Vácuo

MetalZenith utiliza processos de fusão por indução a vácuo e remeltagem por eletroslag para alcançar aço ultra-limpo com mínimas inclusões. Nosso processamento em atmosfera controlada garante uma distribuição ideal de carbonetos e uma vida útil de fadiga aprimorada, crítica para aplicações estruturais de alto desempenho que exigem confiabilidade excepcional.

Teste de Desempenho Abrangente

O nosso aço EN31 passa por testes extensivos, incluindo testes de impacto Charpy, análise de fadiga de feixe rotativo e avaliação especializada da vida útil de rolamentos. Realizamos avaliações minuciosas da endurecibilidade, estabilidade dimensional e padrões de tensão residual para garantir um desempenho ideal em ambientes estruturais exigentes.

Serviços de Tratamento Térmico de Precisão

MetalZenith oferece soluções personalizadas de tratamento térmico, incluindo endurecimento total, endurecimento de superfície e têmpera de precisão com fornos controlados por computador. Nossa expertise metalúrgica garante o desenvolvimento ideal da microestrutura e a otimização das propriedades mecânicas para aplicações estruturais específicas.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações