20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

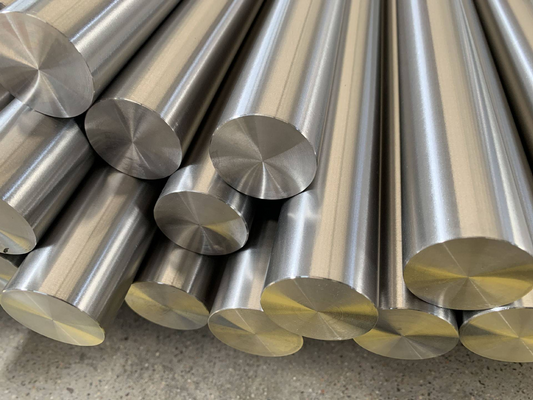

Product Overview

Características Metalúrgicas

O GB L360 é um aço de alta resistência e baixo teor de liga (HSLA) com uma microestrutura predominantemente ferrítica-perlítica, aprimorada por meio de processos de laminação controlada e resfriamento acelerado. O aço alcança suas propriedades mecânicas superiores através do refino de grãos e mecanismos de endurecimento por precipitação, utilizando elementos de microligadura como vanádio, nióbio e titânio.

Processo de Fabricação

A MetalZenith produz o aço GB L360 através de um processo integrado de fabricação de aço que envolve fusão em forno de arco elétrico, refino em panela, fundição contínua e processamento termomecânico controlado. O processo de laminação controlada envolve controle preciso da temperatura durante a deformação a quente, seguido de resfriamento acelerado para alcançar o refino microestrutural ideal e a melhoria das propriedades mecânicas.

Tratamento Térmico e Processamento

O aço GB L360 é tipicamente fornecido na condição de laminado, com resfriamento controlado a partir da temperatura de laminação fornecendo as propriedades mecânicas necessárias. O tratamento térmico de normalização a 900-950°C pode ser aplicado para alívio de tensões e homogeneização microestrutural. O pré-aquecimento para soldagem geralmente não é necessário devido ao baixo equivalente de carbono, embora o tratamento térmico pós-soldagem possa ser especificado para aplicações críticas.

Normas de Qualidade e Testes

Todos os produtos de aço GB L360 fabricados pela MetalZenith estão em conformidade com as normas nacionais GB/T 9711 e as especificações internacionais API 5L. O controle de qualidade abrangente inclui verificação da composição química, testes de tração, testes de impacto Charpy em entalhe em V, medição de dureza e exame não destrutivo, incluindo testes ultrassônicos e inspeção por partículas magnéticas.

Soldabilidade e Fabricação

O aço GB L360 apresenta excelente soldabilidade devido à sua composição química controlada e baixo equivalente de carbono. O aço pode ser soldado utilizando processos convencionais de soldagem a arco, incluindo SMAW, GMAW, GTAW e SAW. Procedimentos de soldagem adequados e soldadores qualificados garantem a integridade das juntas e a correspondência das propriedades mecânicas em aplicações de construção de tubulações.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.24 |

| Manganês (Mn) | 1.00 - 1.45 |

| Silício (Si) | ≤ 0.45 |

| Fósforo (P) | ≤ 0.025 |

| Enxofre (S) | ≤ 0.015 |

| Cromo (Cr) | ≤ 0.30 |

| Níquel (Ni) | ≤ 0.30 |

| Molibdênio (Mo) | ≤ 0.15 |

| Cobre (Cu) | ≤ 0.50 |

| Vanádio (V) | ≤ 0.06 |

| Nióbio (Nb) | ≤ 0.05 |

| Titânio (Ti) | ≤ 0.04 |

| Alumínio (Al) | ≤ 0.06 |

| Equivalente de Carbono (CE) | ≤ 0.43 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (Rt0.5) | 360 - 530 MPa |

| Resistência à Tração (Rm) | 460 - 760 MPa |

| Alongamento (A) | ≥ 22% |

| Relação de Esforço à Tração | ≤ 0.93 |

| Energia de Impacto Charpy V-Notch (0°C) | ≥ 27 J |

| Energia de Impacto Charpy V-Notch (-10°C) | ≥ 40 J |

| Dureza (HV10) | ≤ 250 |

| Módulo de Young | 210 GPa |

| Razão de Poisson | 0.27 - 0.30 |

| Limite de Fadiga (10^7 ciclos) | 180 - 220 MPa |

| Tenacidade à Fratura (KIC) | 150 - 200 MPa·m^0.5 |

| Módulo de Cisalhamento | 80 GPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510 - 1540°C |

| Condutividade Térmica (20°C) | 54 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12×10-6/K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.16 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica | 13.7×10-6 m²/s |

| Emissividade (superfície oxidada) | 0.79 |

| Expansão Térmica (20-200°C) | 13×10-6/K |

| Expansão Térmica (20-400°C) | 14×10-6/K |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Tubos Sem Costura, Tubos Soldados, Placas, Folhas, Bobinas, Barras |

| Faixa de Diâmetro do Tubo | 21.3 - 1422 mm (0.84 - 56 polegadas) |

| Faixa de Espessura da Parede | 2.0 - 80 mm (0.08 - 3.15 polegadas) |

| Faixa de Espessura da Placa | 6 - 150 mm (0.24 - 5.91 polegadas) |

| Comprimentos Padrão | 5.8 - 18 m (Comprimento Aleatório, Comprimento Fixo, Comprimento Duplo Aleatório) |

| Normas de Fabricação | GB/T 9711, API 5L, ISO 3183, EN 10208 |

| Acabamento de Superfície | Preto, Envernizado, Revestido com 3PE, Revestido com FBE, Galvanizado |

| Acabamento de Extremidade | Extremidade Lisa, Extremidade Chanfrada, Rosqueada & Acoplada |

| Tolerância Dimensional | ±1% para OD, ±10% para WT (normas API 5L) |

| Requisitos de Teste | Teste Hidrostático, NDT, Análise Química, Teste Mecânico |

| Certificação | Certificado de Teste de Fábrica, Inspeção de Terceiros Disponível |

| Embalagem | Agrupada, Caixas de Madeira, Estruturas de Aço, Embalagem para Exportação |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing GB L360

Tecnologia Avançada de Laminação Controlada

MetalZenith utiliza processos de laminação controlada por precisão e resfriamento acelerado para alcançar a refinação ideal do grão e propriedades mecânicas no aço GB L360, garantindo força, tenacidade e soldabilidade superiores em comparação com produtos laminados a quente convencionais.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade inclui análise química em tempo real, testes mecânicos automatizados, inspeção ultrassônica e verificação dimensional em cada estágio de produção, garantindo propriedades consistentes do aço GB L360 e documentação de rastreabilidade completa.

Excelência na Cadeia de Suprimentos Global

MetalZenith oferece opções de personalização flexíveis para o aço GB L360, incluindo várias formas de produto, dimensões e acabamentos de superfície, apoiadas por nossa rede de distribuição mundial e serviços de suporte técnico para uma execução de projeto sem interrupções.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações