20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

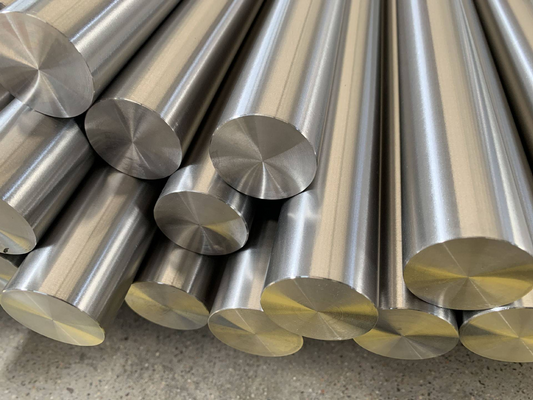

Product Overview

Características Metalúrgicas

O aço EN L415 apresenta uma microestrutura de ferrita-perlita de grão fino, obtida através de processamento termomecânico controlado. A resistência aprimorada do aço deriva do endurecimento por solução sólida, refino de grão e mecanismos de endurecimento por precipitação. Elementos de microaleação, como nióbio e vanádio, contribuem para o refino de grão e o endurecimento por precipitação, mantendo excelentes propriedades de soldabilidade e tenacidade.

Processo de Tratamento Térmico

A MetalZenith emprega laminação controlada avançada seguida de resfriamento acelerado (TMCP) para otimizar a microestrutura do aço. O processo envolve:

- Reaquecimento a 1150-1200°C para homogeneização da austenita

- Laminação controlada na faixa de temperatura de 850-950°C

- Resfriamento acelerado a taxas de 5-15°C/s até 500-600°C

- Resfriamento ao ar até a temperatura ambiente

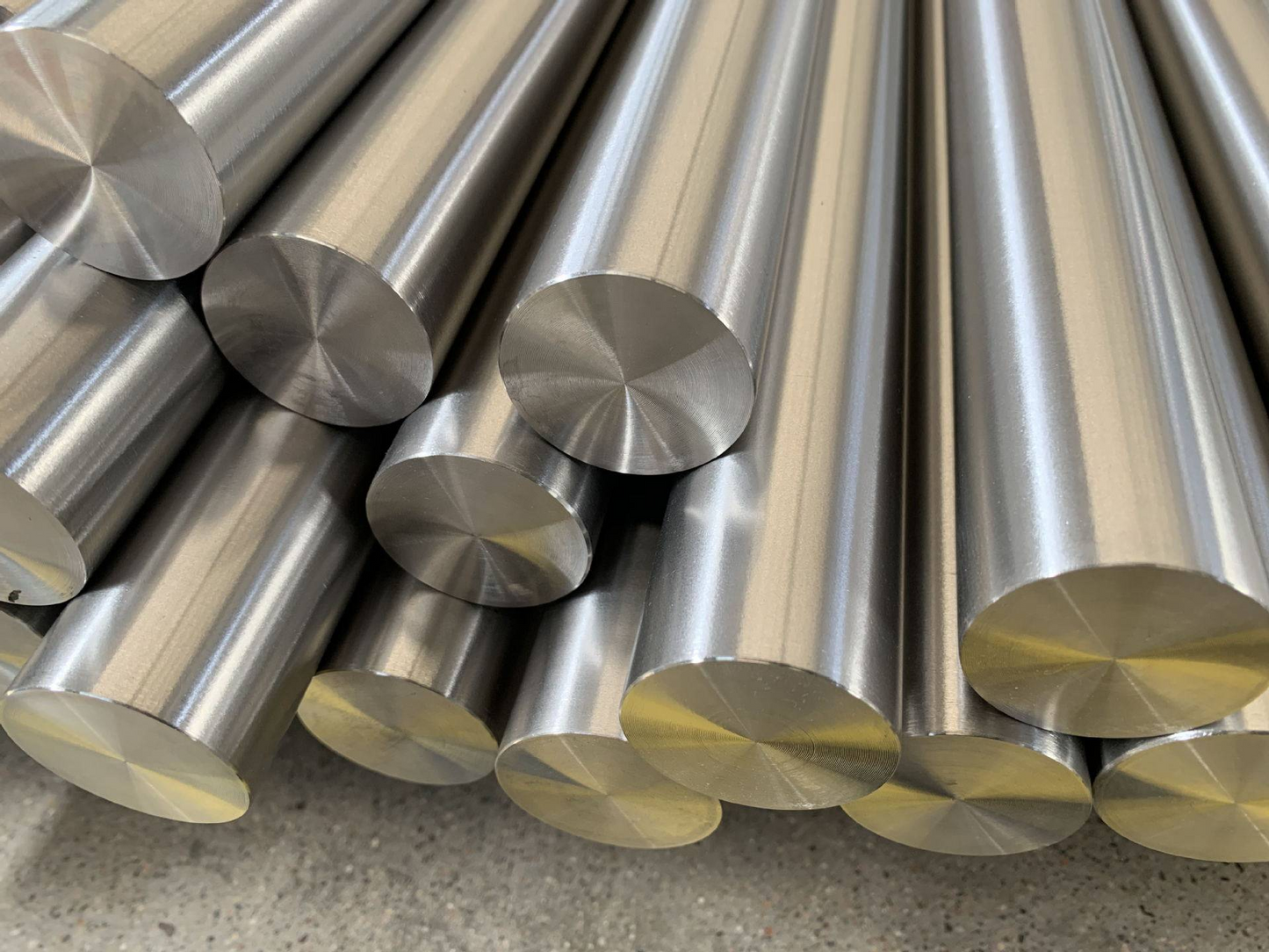

Excelência no Processo de Fabricação

Nossa instalação de produção de última geração utiliza a fabricação de aço em forno a arco elétrico com refino em panela e desgasificação a vácuo para controle preciso da composição química. A fundição contínua garante uma estrutura uniforme, enquanto nossos modernos laminadores proporcionam excepcional precisão dimensional e qualidade de superfície. O monitoramento do processo em tempo real e os sistemas automatizados de controle de qualidade garantem desempenho consistente do produto.

Padrões de Qualidade & Certificações

A MetalZenith mantém conformidade com padrões internacionais, incluindo EN 10208-2, API 5L PSL2 e ISO 3183. Nosso sistema de gestão da qualidade abrange protocolos de teste abrangentes, incluindo análise química, testes mecânicos, testes não destrutivos e verificação dimensional. Cada lote de produto é acompanhado por relatórios de teste certificados e documentação de rastreabilidade de material.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | ≤ 0.24 |

| Manganês (Mn) | 1.20 - 1.60 |

| Silício (Si) | 0.15 - 0.45 |

| Fósforo (P) | ≤ 0.025 |

| Enxofre (S) | ≤ 0.015 |

| Cromo (Cr) | ≤ 0.30 |

| Níquel (Ni) | ≤ 0.30 |

| Molibdênio (Mo) | ≤ 0.15 |

| Cobre (Cu) | ≤ 0.35 |

| Nióbio (Nb) | ≤ 0.05 |

| Vanádio (V) | ≤ 0.06 |

| Titânio (Ti) | ≤ 0.04 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência ao Esforço (Rp0.2) | 415 - 565 MPa |

| Resistência à Tração (Rm) | 520 - 760 MPa |

| Alongamento (A) | ≥ 18% |

| Relação de Esforço para Tração | ≤ 0.93 |

| Energia de Impacto Charpy V-Notch (0°C) | ≥ 40 J |

| Energia de Impacto Charpy V-Notch (-20°C) | ≥ 27 J |

| Dureza (HV10) | ≤ 250 |

| Limite de Fadiga (107 ciclos) | 180 - 220 MPa |

| Tenacidade à Fratura (KIC) | ≥ 150 MPa·m1/2 |

| Módulo de Young | 210 GPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510 - 1540°C |

| Condutividade Térmica (20°C) | 54 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12×10-6/K |

| Capacidade Calorífica Específica | 500 J/kg·K |

| Resistividade Elétrica (20°C) | 0.16 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Razão de Poisson | 0.27 - 0.30 |

| Difusividade Térmica | 13.8 mm²/s |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Tubos Sem Costura, Tubos Soldados, Placas, Folhas, Bobinas |

| Faixa de Diâmetro do Tubo | 21.3 - 1422 mm |

| Faixa de Espessura da Parede | 2.0 - 80.0 mm |

| Faixa de Espessura da Placa | 5.0 - 100.0 mm |

| Conformidade com Normas | EN 10208-2, API 5L, ISO 3183, ASTM A106 |

| Acabamento de Superfície | Preto, Desengraxado, Oleado, Galvanizado |

| Preparação de Extremidade | Extremidade Lisa, Extremidade Chanfrada, Rosqueada |

| Faixa de Comprimento | 5.8 - 18.0 m (Comprimento Aleatório/Fixo) |

| Tolerância Dimensional | ±1% (Diâmetro), ±10% (Espessura da Parede) |

| Requisitos de Teste | Hidroestático, Ultrassônico, Corrente de Foucault |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing L415

Processamento Termomecânico Avançado

MetalZenith emprega tecnologias de laminação controlada e resfriamento acelerado de ponta, garantindo controle microestrutural preciso e propriedades mecânicas ideais. Nosso processo TMCP oferece refinamento de grão consistente e um equilíbrio melhorado entre resistência e tenacidade em toda a matriz de aço.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta monitoramento em tempo real da composição química, testes ultrassônicos avançados e verificação abrangente das propriedades mecânicas. Cada lote passa por testes rigorosos, incluindo testes de impacto Charpy em entalhe em V a várias temperaturas para garantir a confiabilidade.

Soluções de Engenharia Personalizadas

MetalZenith oferece soluções de aço personalizadas com composições químicas sob medida, tratamentos térmicos especializados e tolerâncias dimensionais precisas. Nossa equipe técnica colabora com os clientes para otimizar as propriedades do aço para aplicações específicas em pipelines e condições ambientais.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações