20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

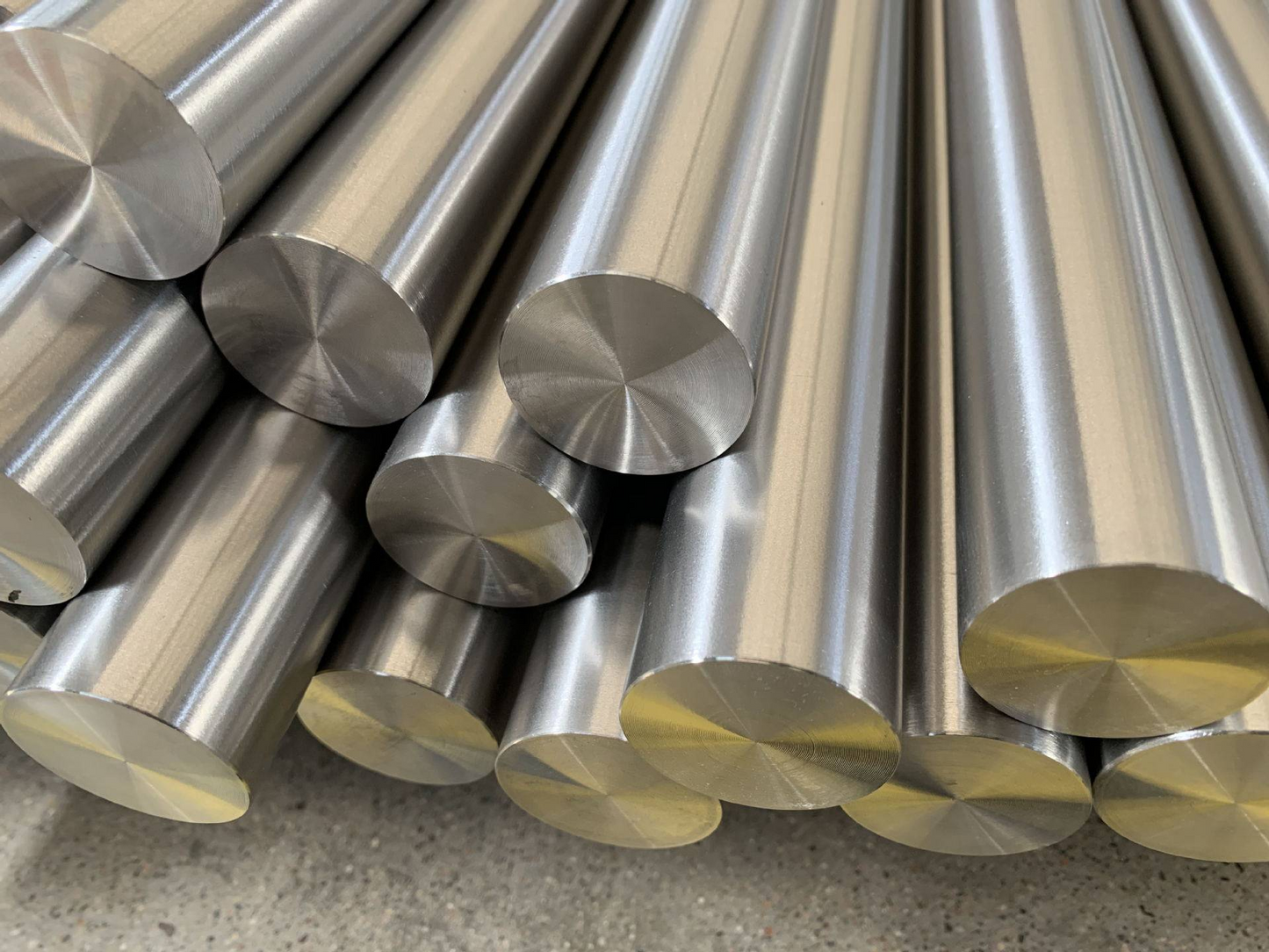

Product Overview

Metallurgical Characteristics

Tin plated structural steel features a low-carbon steel substrate with a fine-grain ferritic-pearlitic microstructure optimized for structural applications. The electrolytic tin coating forms a dense, adherent layer that provides barrier protection against corrosion while maintaining excellent formability and weldability. The tin coating exhibits superior ductility and follows the base steel deformation during forming operations.

Heat Treatment Process

MetalZenith employs controlled annealing at 650-700°C followed by precise cooling to optimize the steel substrate microstructure before coating application. The tin plating process utilizes electrolytic deposition with controlled current density and temperature to ensure uniform coating distribution and optimal adhesion properties.

Manufacturing Process

Our advanced production line includes surface preparation through alkaline cleaning and pickling, followed by electrolytic tin plating in sulfate-based solutions. Post-coating treatments include flow brightening and passivation to enhance corrosion resistance and surface appearance. Quality control monitoring ensures consistent coating thickness and adhesion throughout production.

Specialized Quality Testing

Comprehensive testing protocols include welding performance evaluation using standard structural welding procedures, forming capability assessment through bend testing and deep drawing trials, fatigue strength testing under cyclic loading conditions, and accelerated atmospheric corrosion testing. Additional coating-specific tests include adhesion testing, porosity evaluation, and electrochemical corrosion resistance measurement.

Structural Application Considerations

For building structures, the tin coating provides enhanced durability in humid environments while maintaining structural integrity. Bridge engineering applications benefit from superior atmospheric corrosion resistance and maintained fatigue performance. In machinery manufacturing, the coating enables extended service life in industrial environments. Vehicle manufacturing applications utilize the excellent formability and corrosion protection for structural components. General engineering projects benefit from the versatile combination of structural strength and environmental protection.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.15 - 0.25 |

| Manganese (Mn) | 0.60 - 1.20 |

| Silicon (Si) | 0.15 - 0.40 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.035 |

| Aluminum (Al) | 0.020 - 0.055 |

| Tin Coating (Sn) | 99.85% min purity |

| Iron (Fe) | Balance |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (MPa) | ≥ 355 |

| Tensile Strength (MPa) | 490 - 630 |

| Elongation (%) | ≥ 22 |

| Impact Energy at 20°C (J) | ≥ 27 |

| Hardness (HB) | 140 - 180 |

| Coating Adhesion (N/mm) | ≥ 6.0 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density (g/cm3) | 7.87 |

| Melting Point (°C) | 1510 - 1540 |

| Thermal Conductivity (W/m·K) | 50.2 |

| Thermal Expansion (×10??/K) | 11.8 |

| Elastic Modulus (GPa) | 200 |

| Coating Thickness (μm) | 2.8 - 11.2 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Sheets, Plates, Coils, Strips, Structural Sections |

| Thickness Range | 0.5 - 25mm |

| Width Range | 600 - 2000mm |

| Length Range | 1000 - 12000mm |

| Standards Compliance | ASTM A623, ASTM A653, JIS G3303 |

| Coating Grade | T1-T4 (1.1-11.2g/m2) |

| Surface Finish | Bright, Matte, Passivated |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing Tin Plated Steel (Coated)

Advanced Electrolytic Tin Plating Process

MetalZenith utilizes precision electrolytic tin plating with controlled current density and temperature parameters to achieve uniform coating thickness and superior adhesion. Our advanced plating process ensures optimal tin crystal structure and enhanced corrosion protection while preserving the structural steel's mechanical properties.

Comprehensive Structural Performance Testing

Our quality assurance includes specialized testing for structural applications: welding performance evaluation, forming capability assessment, fatigue strength testing under cyclic loading, and atmospheric corrosion resistance testing. These tests ensure optimal performance in building structures, bridge engineering, and mechanical manufacturing applications.

Custom Coating Solutions & Technical Support

MetalZenith provides tailored tin coating specifications based on specific structural requirements, including custom coating thickness, surface preparation options, and post-coating treatments. Our technical team offers comprehensive support for structural design considerations and application-specific optimization.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications