20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

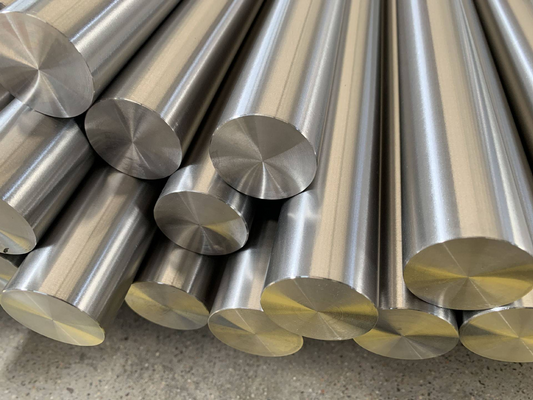

Product Overview

Metallurgical Characteristics

SA533 Grade B is a manganese-molybdenum-nickel low-alloy steel specifically designed for nuclear pressure vessel applications. The alloy composition provides excellent toughness at low temperatures while maintaining high strength and superior weldability. The controlled addition of nickel and molybdenum enhances hardenability and provides resistance to temper embrittlement.

Heat Treatment Process

MetalZenith employs a precise normalize and temper heat treatment cycle. Normalization is performed at 900-950°C followed by air cooling to achieve uniform austenite grain structure. Tempering at 650-680°C develops the required combination of strength and toughness while ensuring compliance with nuclear specifications.

Manufacturing Process

Our production process begins with electric arc furnace melting followed by ladle refining and vacuum degassing to achieve exceptional cleanliness. The steel is cast into ingots and hot forged or rolled to break down the cast structure. Controlled rolling parameters ensure optimal grain refinement and mechanical properties distribution throughout the cross-section.

Quality Standards Compliance

All SA533 Grade B products manufactured by MetalZenith comply with ASME Section III requirements for nuclear components. Our quality system includes 100% ultrasonic testing per ASME Section V, complete chemical analysis, mechanical property verification, and Charpy V-notch impact testing at specified temperatures. Drop weight tear testing ensures adequate fracture toughness for nuclear applications.

Welding Considerations

SA533 Grade B exhibits excellent weldability with proper preheating and post-weld heat treatment. Recommended preheat temperature is 150-200°C depending on thickness. Post-weld heat treatment at 620-650°C is typically required for stress relief and to restore toughness in the heat-affected zone.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.25 |

| Manganese (Mn) | 1.15 - 1.50 |

| Silicon (Si) | 0.15 - 0.40 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Nickel (Ni) | 0.40 - 0.70 |

| Molybdenum (Mo) | 0.45 - 0.60 |

| Chromium (Cr) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.12 |

| Vanadium (V) | ≤ 0.05 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550 - 725 MPa |

| Yield Strength (0.2% offset) | ≥ 345 MPa |

| Elongation in 50mm | ≥ 18% |

| Reduction of Area | ≥ 35% |

| Hardness (Brinell) | 163 - 217 HB |

| Charpy V-Notch Impact (10°C) | ≥ 68 J |

| Drop Weight NDT Temperature | ≤ -12°C |

| Young's Modulus | 200 GPa |

| Fatigue Limit (107 cycles) | 275 MPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 42 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12.5×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.18 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Poisson's Ratio | 0.27 - 0.30 |

| Thermal Diffusivity | 11.6 mm²/s |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Plates, Forgings, Bars, Rings |

| Plate Thickness Range | 8 - 300 mm |

| Plate Width Range | 1000 - 4000 mm |

| Plate Length Range | 2000 - 18000 mm |

| Standards Compliance | ASME SA533, ASTM A533, EN 10028-2 |

| Surface Finish | Hot Rolled, Normalized, Shot Blasted |

| Dimensional Tolerance | ±0.5mm thickness, ±5mm width/length |

| Heat Treatment Condition | Normalized and Tempered |

| Testing Requirements | UT, MT, Chemical Analysis, Mechanical Testing |

| Certification | Mill Test Certificate, EN 10204 3.1/3.2 |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing SA533 Grade B

Nuclear-Grade Manufacturing Technology

MetalZenith employs advanced vacuum induction melting and electroslag remelting processes to achieve exceptional cleanliness and homogeneity required for nuclear applications. Our controlled atmosphere heat treatment facilities ensure precise microstructural control and optimal mechanical properties.

Comprehensive Quality Control System

Our integrated quality management system includes 100% ultrasonic testing, complete chemical analysis, and mechanical property verification. Every plate undergoes Charpy V-notch testing at multiple temperatures to ensure compliance with nuclear toughness requirements.

Custom Engineering Solutions

MetalZenith provides tailored solutions including custom heat treatment schedules, specialized surface finishes, and precise dimensional tolerances. Our technical team works closely with customers to optimize material properties for specific nuclear and pressure vessel applications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications