20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

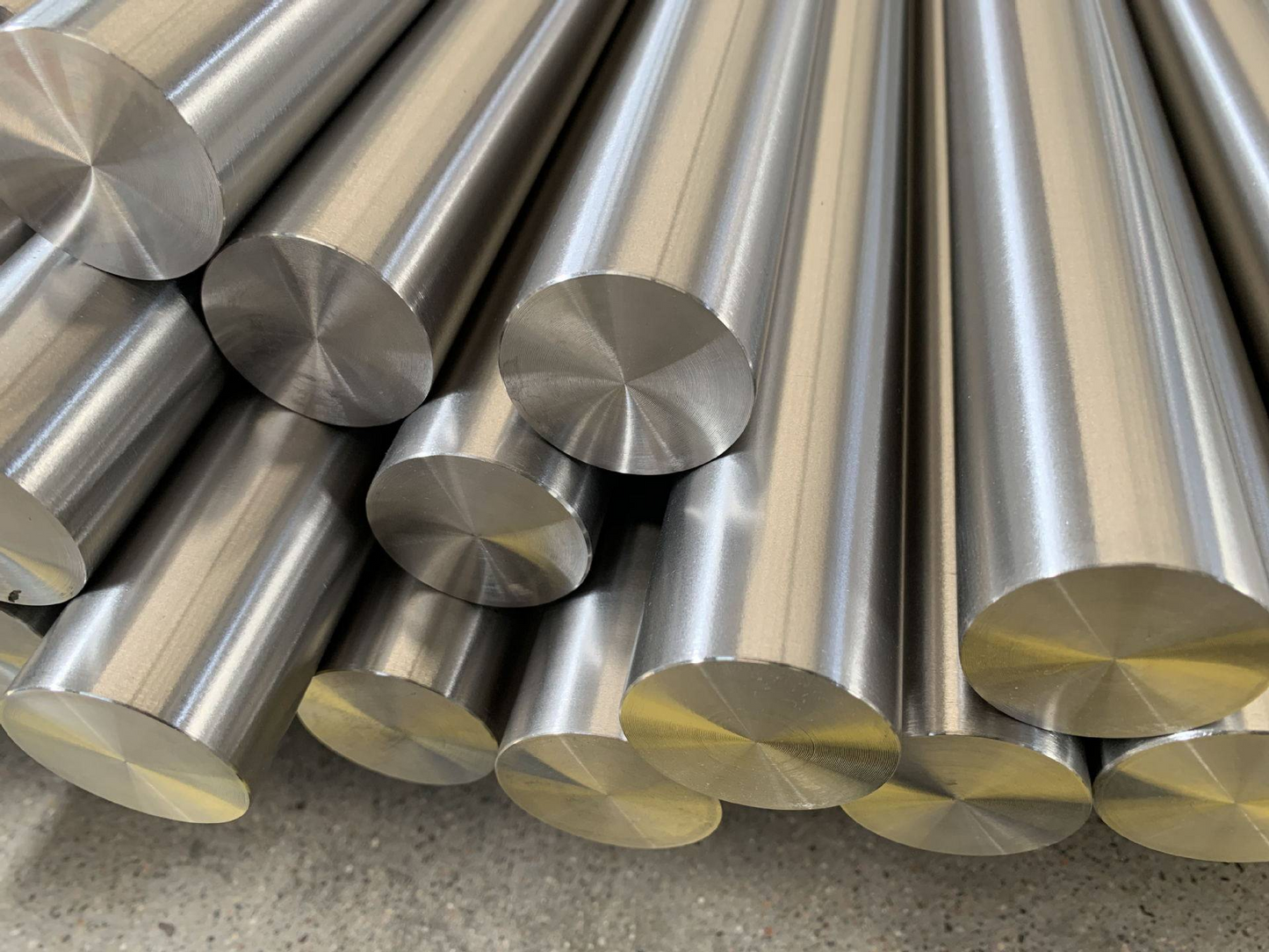

Product Overview

Metallurgical Characteristics

Q245 is a low-carbon structural steel with a predominantly ferritic-pearlitic microstructure. The controlled carbon content and balanced alloying provides excellent weldability while maintaining adequate strength for structural applications. The fine grain structure achieved through controlled rolling enhances both strength and toughness properties.

Heat Treatment Process

MetalZenith employs controlled rolling followed by normalization at 860-920°C with controlled cooling rates to achieve optimal microstructure. This process ensures uniform grain size distribution and eliminates internal stresses, resulting in excellent formability and weldability characteristics essential for structural fabrication.

Manufacturing Process

Our Q245 steel production utilizes advanced electric arc furnace technology with precise temperature control and continuous casting processes. MetalZenith's quality control system monitors chemical composition, mechanical properties, and surface quality throughout production to ensure consistent structural performance.

Structural Quality Testing

Comprehensive testing protocols include welding performance evaluation using standard procedures, forming capability assessment through bend tests, fatigue strength testing under cyclic loading, and atmospheric corrosion resistance evaluation. These specialized tests ensure Q245 steel meets demanding structural application requirements.

Application Engineering

For building structures, Q245 provides excellent strength-to-weight ratio and weldability for frame construction. In bridge engineering, its fatigue resistance and atmospheric corrosion properties ensure long-term durability. For machinery manufacturing, the steel's formability enables complex component fabrication. In vehicle manufacturing, Q245 offers optimal balance of strength and ductility for chassis applications. General engineering applications benefit from its versatile processing characteristics and reliable mechanical properties.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.14 - 0.22 |

| Manganese (Mn) | 0.30 - 0.70 |

| Silicon (Si) | 0.15 - 0.35 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.050 |

| Chromium (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.30 |

| Copper (Cu) | ≤ 0.30 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (MPa) | ≥ 245 |

| Tensile Strength (MPa) | 370 - 500 |

| Elongation (%) | ≥ 26 |

| Impact Energy at 20°C (J) | ≥ 27 |

| Hardness (HB) | 105 - 140 |

| Fatigue Strength (MPa) | 120 - 150 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density (g/cm3) | 7.85 |

| Melting Point (°C) | 1510 - 1540 |

| Thermal Conductivity (W/m·K) | 49.8 |

| Thermal Expansion (×10??/K) | 11.8 |

| Elastic Modulus (GPa) | 200 |

| Poisson's Ratio | 0.27 - 0.30 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Plates, Sheets, Bars, Beams, Angles, Channels |

| Thickness Range | 3 - 80mm |

| Width Range | 1000 - 3000mm |

| Length Range | 6000 - 12000mm |

| Standards Compliance | GB/T 700, ASTM A36 equivalent, EN 10025 |

| Heat Treatment Condition | Hot Rolled, Normalized |

| Surface Finish | Black, Pickled, Primed |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing Q245 Steel

Controlled Rolling and Normalization

MetalZenith employs controlled rolling followed by precise normalization processes with real-time temperature monitoring to achieve optimal grain structure and enhanced mechanical properties. Our advanced processing ensures consistent strength and excellent weldability throughout the material thickness.

Comprehensive Structural Testing

Our Q245 steel undergoes rigorous testing including welding performance evaluation, forming capability assessment, fatigue strength testing, and atmospheric corrosion resistance analysis. This ensures superior performance in structural applications requiring long-term reliability.

Custom Fabrication Services

MetalZenith provides comprehensive custom processing services including cutting, forming, welding preparation, and surface treatment. Our technical support team works closely with customers to optimize Q245 steel specifications for specific structural applications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications