20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

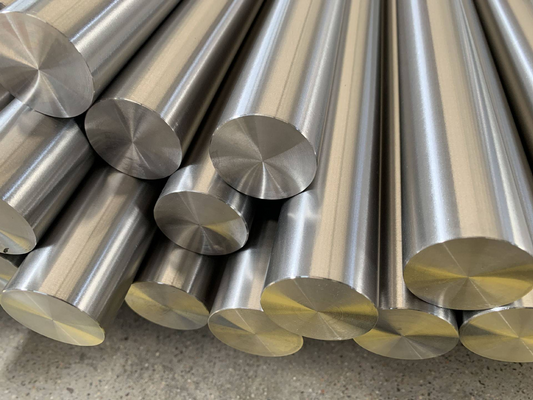

Product Overview

Metallurgical Characteristics

GB 12Cr1MoVR is a low-alloy steel specifically engineered for pressure vessel applications requiring excellent creep resistance and thermal stability. The chromium content provides oxidation resistance and hardenability, while molybdenum enhances high-temperature strength and creep resistance. Vanadium acts as a grain refiner and carbide former, contributing to improved mechanical properties and thermal stability.

Heat Treatment Process

MetalZenith employs a carefully controlled normalize and temper heat treatment cycle. Normalizing is performed at 920-960°C followed by air cooling to achieve uniform austenite grain structure. Tempering is conducted at 680-720°C to develop optimal strength-toughness balance and stress relief. Our computer-controlled furnaces ensure precise temperature uniformity within ±5°C throughout the heating cycle.

Manufacturing Process

Production begins with electric arc furnace melting using high-quality scrap and alloy additions. The molten steel undergoes ladle refining and vacuum degassing to achieve ultra-low sulfur and phosphorus levels. Continuous casting produces high-quality billets which are hot rolled to final dimensions. Critical process parameters including rolling temperature, reduction ratios, and cooling rates are precisely controlled to ensure optimal microstructure development.

Quality Standards and Testing

All products undergo comprehensive testing including chemical analysis by optical emission spectroscopy, mechanical property verification through tensile and impact testing, and non-destructive examination using ultrasonic testing. Microstructural analysis confirms proper heat treatment and absence of harmful phases. MetalZenith maintains full traceability from raw materials through final inspection, ensuring compliance with GB 713 and international pressure vessel codes.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08-0.15 |

| Manganese (Mn) | 0.45-0.70 |

| Silicon (Si) | 0.17-0.37 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.015 |

| Chromium (Cr) | 1.00-1.50 |

| Molybdenum (Mo) | 0.45-0.65 |

| Vanadium (V) | 0.15-0.30 |

| Nickel (Ni) | ≤ 0.30 |

| Copper (Cu) | ≤ 0.20 |

| Aluminum (Al) | ≥ 0.020 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (Rm) | 510-680 MPa |

| Yield Strength (Rp0.2) | ≥ 295 MPa |

| Elongation (A) | ≥ 20% |

| Reduction of Area (Z) | ≥ 50% |

| Brinell Hardness (HB) | 153-207 |

| Impact Energy (KV2) at 20°C | ≥ 34 J |

| Impact Energy (KV2) at 0°C | ≥ 27 J |

| Fatigue Limit (10^7 cycles) | 240-280 MPa |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.30 |

| Creep Rupture Strength (100,000h at 540°C) | ≥ 137 MPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1480-1520°C |

| Thermal Conductivity (20°C) | 42 W/m·K |

| Thermal Conductivity (540°C) | 35 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 11.5×10-6/K |

| Thermal Expansion Coefficient (20-540°C) | 12.8×10-6/K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.28 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity (20°C) | 11.6×10-6 m²/s |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Plates, Sheets, Bars, Forgings, Tubes, Pipes |

| Plate Thickness | 6-200 mm |

| Sheet Thickness | 0.5-6 mm |

| Bar Diameter | 10-300 mm |

| Tube Outer Diameter | 15-600 mm |

| Wall Thickness (Tubes) | 2-50 mm |

| Standards Compliance | GB 713, ASME SA-387, EN 10028-2 |

| Surface Finish | Hot Rolled, Normalized, Pickled, Machined |

| Dimensional Tolerance | ±0.1-0.5 mm (depending on form) |

| Length Range | Up to 12 meters |

| Heat Treatment Condition | Normalized and Tempered |

| Testing Certificates | Mill Test Certificate, Third-Party Inspection |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing GB 12Cr1MoVR

Advanced Vacuum Degassing Technology

MetalZenith employs cutting-edge vacuum degassing and ladle refining processes that significantly reduce hydrogen, oxygen, and nitrogen content, resulting in superior steel purity and enhanced mechanical properties with improved impact toughness and fatigue resistance.

Precision Heat Treatment Control

Our computer-controlled heat treatment facilities ensure precise temperature uniformity and cooling rates, guaranteeing optimal microstructure development and consistent mechanical properties throughout the entire cross-section of each product with full traceability documentation.

Comprehensive Customization Capabilities

MetalZenith offers extensive customization options including non-standard dimensions, special surface finishes, and tailored chemical compositions to meet specific application requirements, supported by our global logistics network ensuring timely delivery worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications