20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

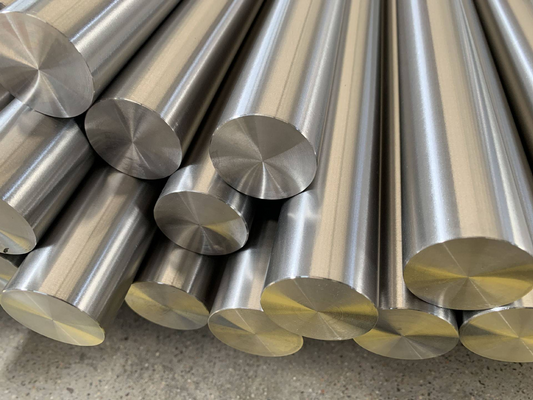

Product Overview

Metallurgische Eigenschaften

SA537 Klasse 1 ist ein normalisierter Kohlenstoff-Mangan-Stahl mit verbesserten Festigkeitseigenschaften, die durch kontrollierte chemische Zusammensetzung und thermomechanische Verarbeitung erreicht werden. Der Stahl weist eine feinkörnige ferritisch-perlitische Mikrostruktur auf, die eine hervorragende Kombination aus Festigkeit, Zähigkeit und Schweißbarkeit bietet. Der Mangananteil trägt zur Festigkeitssteigerung durch feste Lösung bei und erhält gleichzeitig eine gute Duktilität und Schlagfestigkeit bei niedrigen Temperaturen.

Wärmebehandlungsprozess

MetalZenith verwendet eine kontrollierte Normalisierungswärmebehandlung bei 900-950°C, gefolgt von Luftkühlung, um optimale mechanische Eigenschaften zu erreichen. Dieser Prozess verfeinert die Kornstruktur und sorgt für eine gleichmäßige Verteilung von Karbiden im gesamten Gefüge. Eine optionale Spannungsabbau-Glühbehandlung bei 580-650°C kann durchgeführt werden, um Restspannungen in geschweißten Komponenten zu reduzieren. Unsere modernen Wärmebehandlungsanlagen verfügen über präzise Temperaturregelung und Atmosphärenmanagementsysteme.

Herstellungsprozess

Die Produktion beginnt mit dem Schmelzen im Lichtbogenofen unter Verwendung sorgfältig ausgewählter Rohmaterialien, gefolgt von der Pfannenverfeinerung und Vakuumentgasung, um eine überlegene Stahlreinheit zu erreichen. Die kontinuierliche Gießung produziert hochwertige Brammen, die in unseren hochmodernen Walzwerken kontrolliert gewalzt werden. Die thermomechanische kontrollierte Verarbeitung (TMCP) gewährleistet eine feine Kornstruktur und optimale mechanische Eigenschaften. Die Endbearbeitung umfasst präzises Schneiden, Oberflächenbehandlung und umfassende Qualitätsinspektion.

Qualitätsstandards und Zertifizierungen

Alle von MetalZenith hergestellten SA537 Klasse 1 Produkte entsprechen den ASTM A537/A537M und ASME SA537 Spezifikationen. Unser Qualitätsmanagementsystem ist nach ISO 9001:2015 zertifiziert, und wir halten ASME 'S' und 'U' Stempelzertifizierungen für Druckbehälteranwendungen. Jede Produktlieferung enthält Prüfzeugnisse mit vollständiger chemischer Analyse, mechanischen Prüfergebnissen und Ultraschallinspektionsberichten. Drittanbieterinspektions- und Testdienstleistungen sind auf Anfrage verfügbar, um spezifische Kundenanforderungen zu erfüllen.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.24 |

| Mangan (Mn) | 0.70 - 1.35 |

| Silizium (Si) | 0.15 - 0.50 |

| Phosphor (P) | ≤ 0.035 |

| Schwefel (S) | ≤ 0.035 |

| Chrom (Cr) | ≤ 0.25 |

| Nickel (Ni) | ≤ 0.25 |

| Molybdän (Mo) | ≤ 0.08 |

| Kupfer (Cu) | ≤ 0.35 |

| Aluminium (Al) | ≥ 0.020 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Zugfestigkeit | 485 - 620 MPa |

| Streckgrenze (0,2% Offset) | ≥ 345 MPa |

| Dehnung in 200mm | ≥ 18% |

| Dehnung in 50mm | ≥ 21% |

| Brinell-Härte (HB) | 137 - 187 |

| Schlagenergie (Charpy V-Kerbe bei 0°C) | ≥ 27 J |

| Schlagenergie (Charpy V-Kerbe bei -18°C) | ≥ 20 J |

| Flächenreduktion | ≥ 38% |

| Ermüdungsgrenze (107 Zyklen) | 240 MPa |

| Elastizitätsmodul | 200 GPa |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 7.85 g/cm³ |

| Schmelzpunkt | 1510°C |

| Wärmeleitfähigkeit (bei 20°C) | 52 W/m·K |

| Wärmeausdehnungskoeffizient (20-100°C) | 12.5×10-6/K |

| Spezifische Wärmekapazität | 460 J/kg·K |

| Elektrische Widerstandsfähigkeit | 0.18 µΩ·m |

| Magnetische Permeabilität | Ferromagnetisch |

| Poisson-Zahl | 0.27 - 0.30 |

| Wärmediffusivität | 14.4 mm²/s |

| Curie-Temperatur | 770°C |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen |

|---|---|

| Produktformen | Platten, Bleche, Stangen, Schmiedeteile, Coils |

| Plattenstärke | 6mm - 200mm |

| Blechstärke | 0.5mm - 6mm |

| Breitenbereich | 1000mm - 3000mm |

| Längenbereich | 2000mm - 12000mm |

| Einhaltung von Standards | ASTM A537, ASME SA537, EN 10028-3 |

| Oberflächenfinish | Warmgewalzt, Normalisiert, Entzundert, Strahlgebläßt |

| Kantenzustand | Walzkante, Geschnitten, Brennschneiden, Bearbeitet |

| Dicken-Toleranz | ±0.3mm (für Platten ≤20mm) |

| Breiten-Toleranz | ±5mm |

| Längen-Toleranz | ±10mm |

| Planheit | ≤5mm/m |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing SA537 Klasse 1

Fortgeschrittene Lichtbogenofen-Technologie

MetalZenith nutzt modernste Lichtbogenofen-Technologie mit präziser Temperaturkontrolle und fortschrittlichen Pfannenmetallurgie-Systemen, die eine konsistente chemische Zusammensetzung und überlegene Stahlreinheit für die Produktion von SA537 Klasse 1 gewährleisten.

Umfassende Qualitätskontrollsysteme

Unser integriertes Qualitätsmanagementsystem verfügt über Echtzeitüberwachung, automatisierte Testgeräte und zertifizierte Laboranlagen, die garantieren, dass jedes SA537 Klasse 1-Produkt die ASTM-Spezifikationen erfüllt oder übertrifft, mit vollständiger Rückverfolgbarkeitsdokumentation.

Benutzerdefinierte Verarbeitung und globale Versorgung

MetalZenith bietet umfangreiche Anpassungsmöglichkeiten, einschließlich präziser Schneid-, Wärmebehandlungs- und Oberflächenbearbeitungsdienste, unterstützt durch unser globales Vertriebsnetz, das eine pünktliche Lieferung von SA537 Klasse 1 Stahl weltweit gewährleistet.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen