20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

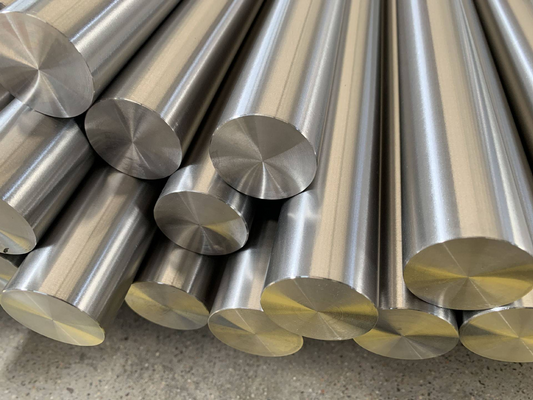

Product Overview

Metallurgische Eigenschaften

SA516 Grad 70 ist ein Kohlenstoff-Mangan-Stahl mit einer ferritisch-perlitischen Mikrostruktur, die für Druckbehälteranwendungen optimiert ist. Der kontrollierte Kohlenstoffgehalt (≤0.30%) gewährleistet eine ausgezeichnete Schweißbarkeit bei gleichzeitiger Aufrechterhaltung einer angemessenen Festigkeit. Der Mangananteil (0.85-1.20%) sorgt für eine solide Lösungshärtung und verbessert die Härtbarkeit. Die feinkörnige Struktur, die durch kontrolliertes Walzen erreicht wird, erhöht die Zähigkeit und Schlagfestigkeit.

Wärmebehandlungsprozess

MetalZenith verwendet präzise Wärmebehandlungsprotokolle, einschließlich kontrollierter Abkühlung von der Walztemperatur oder Normalisierung bei 900-950°C, gefolgt von Luftabkühlung. Eine Spannungsabbau-Wärmebehandlung bei 580-650°C kann für dicke Abschnitte oder komplexe Geometrien angewendet werden. Unsere fortschrittlichen Ofensteuerungssysteme gewährleisten eine gleichmäßige Temperaturverteilung und eine optimale mikrostrukturelle Entwicklung.

Exzellenz im Fertigungsprozess

Die Produktion beginnt mit sorgfältig ausgewählten Rohmaterialien, die in Lichtbogenöfen mit Pfannenverfeinerung für eine präzise Chemiekontrolle geschmolzen werden. Die kontinuierliche Gießung produziert hochwertige Brammen mit minimaler Segregation. Das Warmwalzen erfolgt bei kontrollierten Endtemperaturen, um die optimale Korngröße zu erreichen. Eine fortschrittliche Prozessüberwachung gewährleistet konsistente mechanische Eigenschaften während des gesamten Produktionslaufs.

Qualitätsstandards & Prüfung

Alle SA516 Grad 70 Produkte unterliegen umfassenden Tests gemäß den Anforderungen von ASTM A516, einschließlich chemischer Analyse, Zugversuch, Charpy-Schlagprüfung und Ultraschalluntersuchung. Zusätzliche Tests umfassen Härteüberprüfung, Makro-Ätzuntersuchung und Korngrößenbestimmung. Dienstleistungen von Dritten zur Inspektion und Zeugenprüfungen sind verfügbar. Vollständige Dokumentation umfasst Prüfzeugnisse, Wärmebehandlungsdiagramme und Rückverfolgbarkeitsunterlagen.

Schweißüberlegungen

SA516 Grad 70 weist eine ausgezeichnete Schweißbarkeit mit niedrigem Kohlenstoffäquivalent (typischerweise 0.40-0.45%) auf. Eine Vorwärmung ist in der Regel nicht erforderlich für Abschnitte bis zu 25 mm Dicke. Eine Nachschweißwärmebehandlung kann für Spannungsabbau vorgeschrieben werden. Kompatible Schweißzusätze umfassen E7018, ER70S-6 und ähnliche wasserstoffarme Elektroden. Richtige Schweißverfahren gewährleisten eine vollständige Durchdringung und optimale Fügeeigenschaften.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.30 |

| Mangan (Mn) | 0.85 - 1.20 |

| Silizium (Si) | 0.13 - 0.45 |

| Phosphor (P) | ≤ 0.035 |

| Schwefel (S) | ≤ 0.035 |

| Chrom (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.30 |

| Molybdän (Mo) | ≤ 0.12 |

| Kupfer (Cu) | ≤ 0.35 |

| Vanadium (V) | ≤ 0.08 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Zugfestigkeit | 485 - 620 MPa |

| Streckgrenze (0,2% Offset) | ≥ 260 MPa |

| Dehnung (50mm Messschieber) | ≥ 21% |

| Dehnung (200mm Messschieber) | ≥ 17% |

| Brinell-Härte (HB) | 143 - 187 |

| Charpy V-Notch Schlag (bei 0°C) | ≥ 27 J |

| Youngs Modul | 200 - 210 GPa |

| Poisson-Zahl | 0.27 - 0.30 |

| Ermüdungsgrenze (10&sup7; Zyklen) | 240 - 280 MPa |

| Querschnittsreduktion | ≥ 38% |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 7.85 g/cm³ |

| Schmelzpunkt | 1510 - 1540°C |

| Wärmeleitfähigkeit (bei 20°C) | 54 W/m·K |

| Wärmeausdehnungskoeffizient (20-100°C) | 12.0×10-6/K |

| Wärmeausdehnungskoeffizient (20-400°C) | 13.5×10-6/K |

| Spezifische Wärmekapazität | 500 J/kg·K |

| Elektrische Widerstandsfähigkeit (bei 20°C) | 0.16 µΩ·m |

| Magnetische Permeabilität | Ferromagnetisch |

| Curie-Temperatur | 770°C |

| Wärmediffusivität | 13.7 mm²/s |

📏 Product Specifications

| Spezifikation | Verfügbare Optionen |

|---|---|

| Produktformen | Platten, Bleche, Stangen, Schmiedeteile, Rohre |

| Plattenstärke | 6mm - 200mm |

| Blechstärke | 0.5mm - 6mm |

| Breitenbereich | 1000mm - 4000mm |

| Längenbereich | 2000mm - 12000mm |

| Normen-Konformität | ASTM A516, ASME SA516, EN 10028-2 (P355GH) |

| Oberflächenfinish | Warmgewalzt, Normalisiert, Strahlgebläst |

| Maßtoleranz | ASTM A6/A6M, EN 10029 Klasse A/B |

| Kantenzustand | Walzkante, Geschnittene Kante, Brennschneiden |

| Wärmebehandlung | Wie gewalzt, Normalisiert, Spannungsarm geglüht |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing SA516 Grad 70

Fortgeschrittene metallurgische Kontrolle

MetalZenith setzt hochentwickelte Lichtbogenofen-Technologie mit präziser Pfannenverfeinerung ein, um eine optimale chemische Zusammensetzung und Mikrostruktur zu erreichen. Unsere kontrollierten Walz- und Normalisierungsprozesse gewährleisten konsistente mechanische Eigenschaften und eine überlegene Kornverfeinerung für verbesserte Zähigkeit und Schweißbarkeit.

Umfassende Qualitätsprüfung

Jedes SA516 Grade 70 Produkt unterliegt umfangreichen Qualitätsprüfungen, einschließlich spektroskopischer Analyse, Zugversuchen, Charpy-Schlagprüfungen und Ultraschallinspektionen. Unser nach ISO 9001:2015 zertifiziertes Labor gewährleistet die Einhaltung der ASTM A516 und internationaler Druckbehälterstandards.

Maßgeschneiderte Fertigungslösungen

MetalZenith bietet flexible Produktionsmöglichkeiten, einschließlich maßgeschneiderter Wärmebehandlungszyklen, spezifischer Maßtoleranzen und spezieller Oberflächenbehandlungen. Unser globales Lieferkettennetzwerk gewährleistet eine pünktliche Lieferung weltweit mit umfassendem technischen Support und Ingenieurdienstleistungen.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen