20 Jahre Erfahrung | 1000+ Markenpartner | Vollständige Anpassung

Wir haben 20 Jahre Branchenerfahrung, haben mit über 1.000 Marken zusammengearbeitet und unterstützen alle Anpassungsbedürfnisse.

Technical Specifications

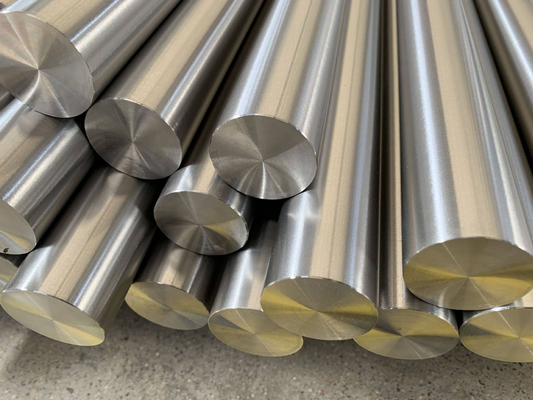

Product Overview

Metallurgische Eigenschaften

FH40 ist ein normalisiertes feinkörniges Baustahl mit einer überwiegend ferritisch-perlitischen Mikrostruktur. Die kontrollierte Zugabe von Mikrolegierungselementen wie Niob, Vanadium und Titan fördert die Kornverfeinerung und Ausfällungsstärkung, was zu einer hervorragenden Kombination aus Festigkeit und Zähigkeit führt, die für Offshore-Anwendungen unerlässlich ist.

Wärmebehandlungsprozess

MetalZenith verwendet kontrolliertes Walzen, gefolgt von Normalisierung bei 900-950°C mit kontrollierten Abkühlraten, um eine optimale mikrostrukturelle Homogenität zu erreichen. Die thermomechanische Bearbeitung gewährleistet eine feine Austenitkornstruktur und eine gleichmäßige Karbidverteilung, die entscheidend für die Erreichung der erforderlichen Schlagzähigkeit bei niedrigen Betriebstemperaturen ist.

Herstellungsprozess

Die Produktion beginnt mit dem Schmelzen im Lichtbogenofen, gefolgt von der Pfannenverfeinerung und Vakuumentgasung, um ultra-niedrige Schwefel- und Phosphorgehalte zu erreichen. Die kontinuierliche Gießung produziert hochwertige Brammen, die kontrolliert gewalzt werden mit präziser Temperaturkontrolle. Die abschließende Normalisierungsbehandlung gewährleistet Spannungsabbau und optimale mechanische Eigenschaften über den Querschnitt.

Qualitätsstandards & Prüfung

Jede Charge unterliegt umfassenden Tests, einschließlich chemischer Analyse, Zugversuchen, Charpy-V-Kerbschlagversuchen bei -40°C und -60°C, Härteprüfungen und Ultraschallinspektionen. Die mikrostrukturelle Untersuchung stellt die Einhaltung der Kornstruktur und das Fehlen schädlicher Einschlüsse sicher. Eine Zertifizierung durch Dritte ist von großen Klassifikationsgesellschaften wie ABS, DNV-GL, Lloyd's Register und Bureau Veritas verfügbar.

Schweißüberlegungen

FH40 weist eine ausgezeichnete Schweißbarkeit mit angemessener Vorwärmung (typischerweise 100-150°C für dicke Abschnitte) und kontrollierten Zwischenpass-Temperaturen auf. Ein niedriger Kohlenstoffäquivalent (CEV ≤ 0.40) gewährleistet ein minimales Risiko von Kaltverzug. Eine Nachschweißwärmebehandlung kann für Spannungsabbau in kritischen Anwendungen erforderlich sein.

🧪 Chemical Composition

| Element | Zusammensetzung (%) |

|---|---|

| Kohlenstoff (C) | ≤ 0.18 |

| Mangan (Mn) | 0.90 - 1.60 |

| Silizium (Si) | 0.10 - 0.50 |

| Phosphor (P) | ≤ 0.030 |

| Schwefel (S) | ≤ 0.025 |

| Aluminium (Al) | ≥ 0.015 |

| Niob (Nb) | 0.02 - 0.05 |

| Vanadium (V) | 0.05 - 0.10 |

| Titan (Ti) | 0.02 - 0.05 |

| Stickstoff (N) | ≤ 0.012 |

| Kupfer (Cu) | ≤ 0.35 |

| Chrom (Cr) | ≤ 0.20 |

| Nickel (Ni) | ≤ 0.40 |

| Molybdän (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| Eigenschaft | Wert |

|---|---|

| Streckgrenze (ReH) | 390 - 510 MPa |

| Zugfestigkeit (Rm) | 510 - 660 MPa |

| Dehnung (A5) | ≥ 20% |

| Schlagenergie (KV bei -40°C) | ≥ 34 J |

| Schlagenergie (KV bei -60°C) | ≥ 24 J |

| Härte (HB) | 150 - 220 |

| Youngs Modul | 206 GPa |

| Poisson-Zahl | 0.30 |

| Ermüdungsgrenze (107 Zyklen) | 180 MPa |

| Bruchzähigkeit (K1C) | 120 MPa·m1/2 |

| Streckverhältnis (ReH/Rm) | ≤ 0.80 |

🔬 Physical Properties

| Eigenschaft | Wert |

|---|---|

| Dichte | 7.85 g/cm³ |

| Schmelzpunkt | 1510°C |

| Wärmeleitfähigkeit (20°C) | 54 W/m·K |

| Wärmeausdehnungskoeffizient (20-100°C) | 12×10-6/K |

| Spezifische Wärmekapazität | 500 J/kg·K |

| Elektrische Widerstandsfähigkeit (20°C) | 0.16 µΩ·m |

| Magnetische Permeabilität | Ferromagnetisch |

| Curie-Temperatur | 770°C |

| Wärmediffusivität | 13.7 mm²/s |

| Koeffizient der linearen Ausdehnung (0-100°C) | 11.5×10-6/K |

📏 Product Specifications

| Spezifikation | Details |

|---|---|

| Verfügbare Formen | Platten, Bleche, Stangen, Profile, Schmiedeteile |

| Plattenstärke Bereich | 6 - 150 mm |

| Blechstärke Bereich | 3 - 12 mm |

| Breitenbereich | 1000 - 4000 mm |

| Längenbereich | 2000 - 18000 mm |

| Einhaltung von Standards | ABS, DNV-GL, LR, BV, NK, CCS, RINA |

| Oberflächenfinish | Warmgewalzt, Normalisiert, Strahlgebläßt |

| Kantenzustand | Walzkante, Geschnitten, Brennschneiden, Bearbeitet |

| Dicken-Toleranz | ±0.3 mm (6-40mm), ±0.5 mm (>40mm) |

| Breiten-Toleranz | ±5 mm |

| Längen-Toleranz | ±10 mm |

| Planheit | ≤ 5 mm/m |

Lassen Sie uns Erfolg für Ihr Projekt schaffen

Professionelles Team, Premium-Produkte, Vollständiger Service - Ihr Projekterfolg ist unsere Mission

Our Advantages in Processing FH40

Fortgeschrittene thermomechanische Verarbeitung

MetalZenith verwendet kontrolliertes Walzen und präzise Normalisierungsprozesse mit Echtzeit-Temperaturüberwachung, um eine optimale Kornstruktur und verbesserte mechanische Eigenschaften zu erreichen. Unsere fortschrittliche Verarbeitung gewährleistet eine gleichmäßige Zähigkeit und Festigkeit über die gesamte Materialdicke.

Umfassende Qualitätsprüfung

Unsere hochmodernen Testeinrichtungen führen umfassende mechanische Tests durch, einschließlich Charpy-V-Kerbschlagprüfungen bei -40°C, Ultraschallinspektionen und mikrostrukturellen Analysen. Jede Charge unterliegt einer strengen Qualitätsprüfung, um die Standards der Offshore-Klassifikationsgesellschaften zu erfüllen.

Maßgeschneiderte Offshore-Lösungen

MetalZenith bietet maßgeschneiderte Verarbeitungslösungen, einschließlich kundenspezifischer Wärmebehandlung, präziser Schneidetechniken und spezialisierter Oberflächenbehandlungen. Unser Ingenieurteam bietet technische Unterstützung für spezifische Offshore-Anwendungen mit globalen Logistikfähigkeiten für eine pünktliche Lieferung.

IHR VERTRAUENwürdiger STAHL

HERSTELLUNGSPARTNER

Schnellanfrage

Branchen, die wir bedienen

Professionelle Stahl-Lösungen in wichtigen Branchen

Qualifikationen & Zertifizierungen