20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

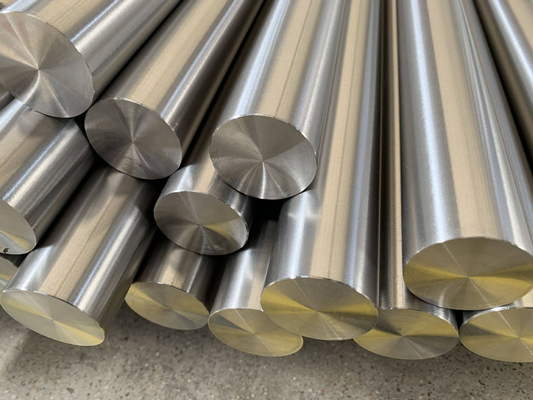

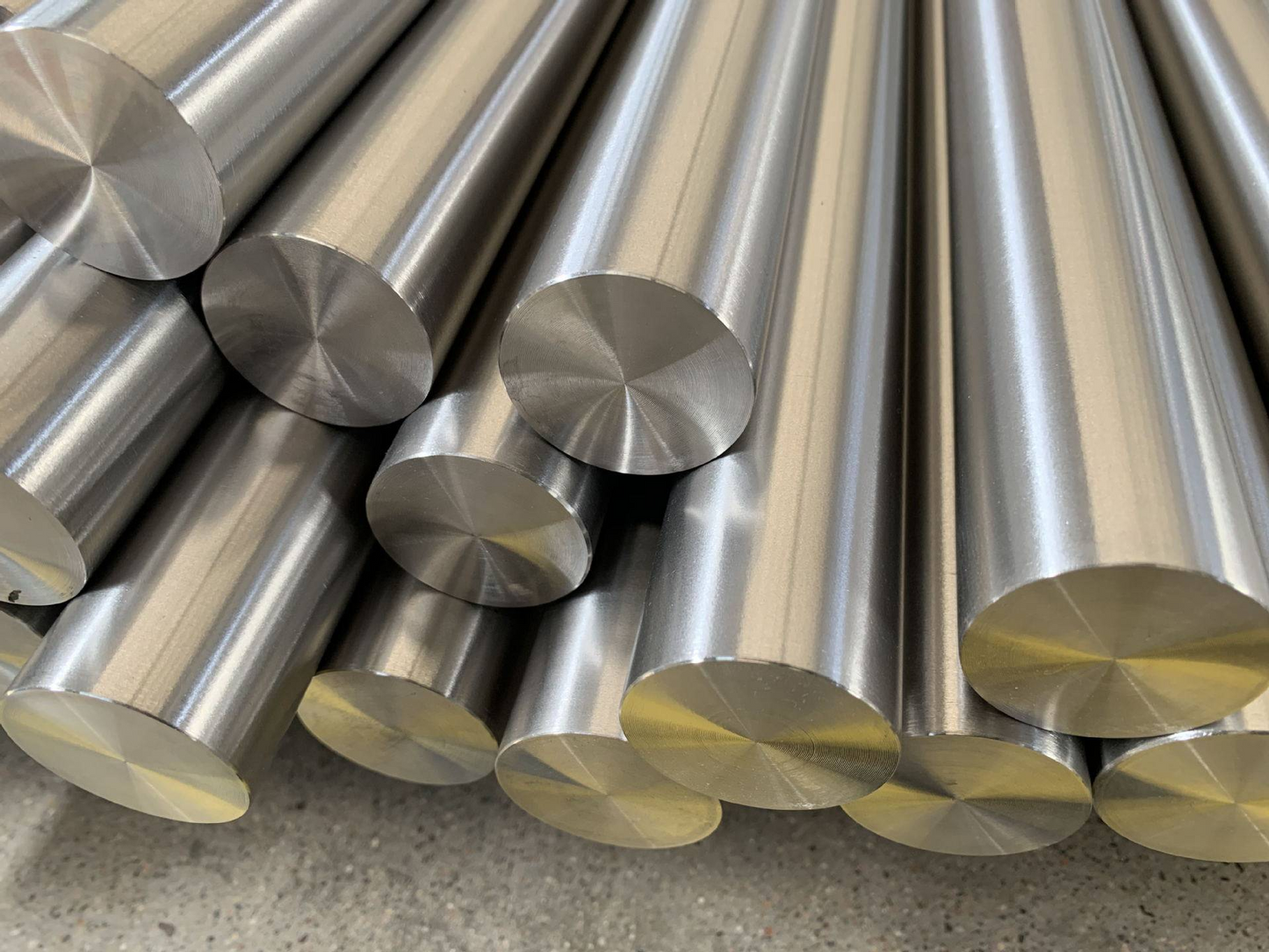

Product Overview

الخصائص المعدنية

UNS N08020 هو فولاذ مقاوم للصدأ من النوع الأوستنيتي مع هيكل بلوري مكعب مركزي الوجه يظل مستقرًا عبر نطاق واسع من درجات الحرارة. إن مقاومة الصدأ الاستثنائية للسبيكة تنبع من تركيبها المتوازن من الكروم والنيكل والموليبدينوم والنحاس، مما يشكل طبقة أكسيد سلبية واقية للغاية. إن إضافة النيوبيوم توفر الاستقرار ضد ترسيب الكربيد، مما يضمن مقاومة طويلة الأمد للصدأ في نطاقات درجات الحرارة الحساسة.

عملية المعالجة الحرارية

تستخدم MetalZenith معالجة دقيقة من التلدين في محلول عند 1120-1150°C تليها تبريد سريع بالماء لتحقيق الخصائص المثلى. هذه المعالجة تذوب الكربيدات وتضمن هيكل أوستنيتي متجانس. تمنع أفراننا ذات الجو المسيطر أكسدة السطح وتحافظ على استقرار الأبعاد. تعزز عمليات التنظيف بعد التلدين والمعالجة السلبية مقاومة الصدأ وجودة السطح.

تميز عملية التصنيع

تبدأ عملية التصنيع لدينا بالذوبان بالتحريض في الفراغ باستخدام مواد خام عالية الجودة، تليها إعادة الذوبان بالكهرباء لتحسين النظافة. تُجرى عمليات العمل الساخن ضمن نوافذ درجات حرارة دقيقة (1050-1200°C) لتحسين هيكل الحبوب. تستخدم عمليات العمل البارد تقنيات متقدمة في الدرفلة والسحب لتحقيق تشطيب سطحي متفوق ودقة أبعاد مع الحفاظ على الخصائص الميكانيكية.

معايير الجودة والاختبار

تخضع كل دفعة إنتاج لاختبارات شاملة تشمل التحليل الكيميائي بواسطة طيفية الانبعاث الضوئي، والاختبارات الميكانيكية وفقًا لمعايير ASTM، واختبارات تآكل الحبيبات (ASTM A262 Practice E)، وفحص الميكروهيكل. تضمن الاختبارات غير التدميرية بما في ذلك الفحص بالموجات فوق الصوتية واختبار التيار الدوامي سلامة داخلية. يتم توفير شهادات اختبار المصنع الكاملة وتقارير الفحص من طرف ثالث مع كل شحنة، مما يضمن تتبعًا كاملاً والامتثال لمعايير الجودة الدولية.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.07 |

| المنغنيز (Mn) | ≤ 2.00 |

| السيليكون (Si) | ≤ 1.00 |

| الفوسفور (P) | ≤ 0.045 |

| الكبريت (S) | ≤ 0.035 |

| الكروم (Cr) | 19.0 - 21.0 |

| النيكل (Ni) | 32.0 - 38.0 |

| الموليبدينوم (Mo) | 2.0 - 3.0 |

| النحاس (Cu) | 3.0 - 4.0 |

| النيوبوم (Nb) | 8 × C min, 1.0 max |

| الحديد (Fe) | التوازن |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد | ≥ 550 MPa (80 ksi) |

| قوة الخضوع (0.2% انحراف) | ≥ 240 MPa (35 ksi) |

| التمدد في 50 مم | ≥ 30% |

| تخفيض المساحة | ≥ 50% |

| الصلابة (برينيل) | ≤ 217 HB |

| الصلابة (روكويل ب) | ≤ 95 HRB |

| طاقة الصدمة (شاربي V-notch عند 20°C) | ≥ 100 J |

| حد التعب (107 دورة) | 240 MPa |

| معامل المرونة | 200 GPa |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.08 جرام/سم³ |

| نقطة الانصهار | 1350-1400°م |

| التوصيل الحراري (عند 100°م) | 16.3 واط/م·ك |

| التوسع الحراري (20-100°م) | 14.2×10-6/ك |

| التوسع الحراري (20-300°م) | 15.1×10-6/ك |

| السعة الحرارية النوعية | 460 جول/كجم·ك |

| المقاومة الكهربائية (عند 20°م) | 1.02 µΩ·م |

| نفاذية مغناطيسية | 1.02 (غير مغناطيسي أساساً) |

| درجة حرارة كوري | غير قابل للتطبيق (أوستنيتي) |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | أشرطة دائرية، أشرطة مربعة، أشرطة مسطحة، لوحات، صفائح، شرائط، أنابيب، مواسير، تشكيلات |

| أحجام الأشرطة الدائرية | 6mm - 300mm قطر |

| سمك اللوحات | 3mm - 100mm |

| سمك الصفائح | 0.5mm - 6mm |

| أحجام الأنابيب | 6mm - 219mm OD، 0.5mm - 20mm سمك الجدار |

| الامتثال للمعايير | ASTM B729، ASME SB-729، UNS N08020، DIN 2.4660 |

| تشطيبات السطح | مدرفلة على الساخن، مدرفلة على البارد، مشبعة ساطعة، مخللة، مصقولة (2B، BA، No.4، No.8) |

| ت tolerances الأبعاد | ±0.1mm إلى ±0.5mm حسب شكل المنتج وحجمه |

| خيارات الطول | أطوال قياسية 3م، 6م، 12م أو مقطعة حسب متطلبات العميل |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing UNS N08020

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith تقنية الصهر بالتحريض الفراغي المتطورة (VIM) تليها إعادة الصهر بالتيار الكهربائي (ESR) لتحقيق تجانس كيميائي استثنائي ومحتوى منخفض للغاية من الشوائب في UNS N08020، مما يضمن مقاومة ممتازة للتآكل وخصائص ميكانيكية فائقة.

نظام شامل لمراقبة الجودة

يؤدي مختبرنا المتطور اختبارات شاملة للتحليل الكيميائي، واختبارات ميكانيكية، واختبارات تآكل بين الحبيبات (ASTM A262)، وفحص الميكروهيكل على كل دفعة، مما يضمن جودة متسقة والامتثال للمعايير الدولية.

معالجة مخصصة والإمداد العالمي

تقدم MetalZenith إمكانيات تخصيص واسعة تشمل التشغيل الدقيق، وتحسين معالجة الحرارة، ومعالجات السطح المتخصصة، مدعومة بشبكة توزيع عالمية تضمن التسليم في الوقت المناسب لمنتجات UNS N08020 في جميع أنحاء العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات