20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

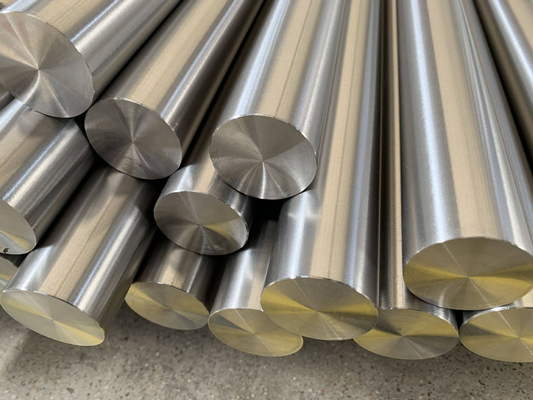

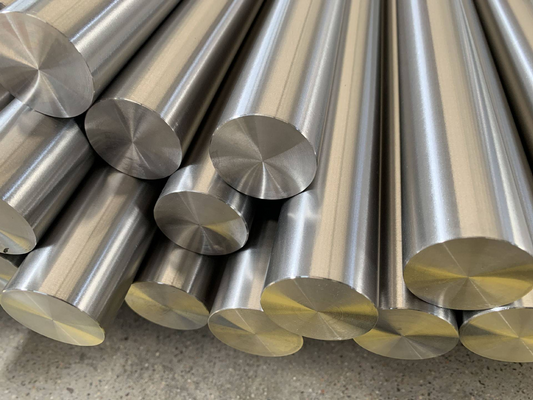

Product Overview

الخصائص المعدنية

GH3625 هو سبيكة فائقة من النيكل والكروم والموليبدينوم مقواة بالحلول الصلبة مع مقاومة استثنائية للأكسدة والتآكل. تظل بنية السبيكة الأوستنيتية مستقرة عبر نطاق واسع من درجات الحرارة، بينما توفر إضافات النيوبيوم تقوية بالتساقط من خلال تشكيل مراحل غاما-دوبل-برايم (γ'') ودلتا (δ). يضمن محتوى الموليبدينوم والكروم العالي مقاومة فائقة للتآكل الناتج عن الحفر، وتآكل الشقوق، وتصدع التآكل الناتج عن الضغط.

عملية المعالجة الحرارية

تستخدم MetalZenith بروتوكولات معالجة حرارية دقيقة لـ GH3625، بما في ذلك التلدين في المحلول عند 1150-1177°C يتبعه تبريد سريع لتحقيق الخصائص الميكانيكية المثلى. يمكن تطبيق علاجات تقوية الشيخوخة عند 650-750°C لتعزيز القوة من خلال التساقط المنضبط لمراحل التقوية. تضمن أفراننا ذات الجو المنضبط نتائج متسقة وتمنع الأكسدة أثناء المعالجة.

عملية التصنيع

تبدأ إنتاجية GH3625 لدينا بصهر التحريض الفراغي (VIM) للمواد الخام عالية النقاء، يتبعها إعادة صهر القوس الفراغي (VAR) أو إعادة صهر الكهرومغناطيسية (ESR) لتحقيق نظافة وتجانس فائقة. يتم تنفيذ عمليات العمل الساخن بما في ذلك التشكيل، والدرفلة، والبثق ضمن نطاقات درجات حرارة مضبوطة بعناية لتحسين بنية الحبيبات والخصائص الميكانيكية. يتم استخدام عمليات العمل البارد ودورات التلدين الوسيطة للتحكم الدقيق في الأبعاد.

معايير الجودة والاختبار

تحافظ MetalZenith على مراقبة جودة شاملة طوال إنتاج GH3625، بما في ذلك التحليل الكيميائي بواسطة مطيافية الانبعاث الضوئي (OES) ومطيافية الأشعة السينية (XRF)، والاختبار الميكانيكي وفقًا لمعايير ASTM، والاختبار بالموجات فوق الصوتية للسلامة الداخلية، وفحص البنية المجهرية. تتوافق جميع المنتجات مع مواصفات الطيران بما في ذلك AMS 5599 والمعايير النووية مثل ASME Section III. يتم توفير تتبع المواد الكامل والوثائق مع كل شحنة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| نيكل (Ni) | 58.0 كحد أدنى |

| كروم (Cr) | 20.0-23.0 |

| موليبدينوم (Mo) | 8.0-10.0 |

| نيوبيم + تانتالوم (Nb+Ta) | 3.15-4.15 |

| حديد (Fe) | ≤ 5.0 |

| كربون (C) | ≤ 0.10 |

| منغنيز (Mn) | ≤ 0.50 |

| سيليكون (Si) | ≤ 0.50 |

| فوسفور (P) | ≤ 0.015 |

| كبريت (S) | ≤ 0.015 |

| ألمنيوم (Al) | ≤ 0.40 |

| تيتانيوم (Ti) | ≤ 0.40 |

| كوبالت (Co) | ≤ 1.0 |

⚙️ Mechanical Properties

| الخاصية | القيمة | حالة الاختبار |

|---|---|---|

| قوة الشد | ≥ 827 MPa | درجة حرارة الغرفة |

| قوة الخضوع (0.2% انزياح) | ≥ 414 MPa | درجة حرارة الغرفة |

| التمدد | ≥ 30% | درجة حرارة الغرفة |

| تقليل المساحة | ≥ 50% | درجة حرارة الغرفة |

| الصلابة (HB) | 240-290 | حالة التلدين |

| الصلابة (HRC) | 25-32 | حالة التلدين |

| طاقة الصدمة (شاربي V-notch) | ≥ 120 J | درجة حرارة الغرفة |

| قوة التعب (107 دورة) | 380 MPa | درجة حرارة الغرفة |

| معامل يونغ | 208 GPa | درجة حرارة الغرفة |

| معامل القص | 81 GPa | درجة حرارة الغرفة |

| نسبة بواسون | 0.31 | درجة حرارة الغرفة |

🔬 Physical Properties

| الخاصية | القيمة | درجة الحرارة |

|---|---|---|

| الكثافة | 8.44 جرام/سم³ | 20°م |

| نقطة الانصهار | 1290-1350°م | - |

| التوصيل الحراري | 9.8 واط/م·ك | 20°م |

| التوصيل الحراري | 19.4 واط/م·ك | 540°م |

| السعة الحرارية النوعية | 410 جول/كجم·ك | 20°م |

| معامل التمدد الحراري | 12.8×10-6/ك | 20-100°م |

| معامل التمدد الحراري | 14.6×10-6/ك | 20-650°م |

| المقاومة الكهربائية | 1.29 µΩ·م | 20°م |

| نفاذية مغناطيسية | 1.0008 | درجة حرارة الغرفة |

| درجة حرارة كوري | -196°م | - |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتجات | قضبان دائرية، قضبان مربعة، قضبان مسطحة، لوحات، صفائح، شرائط، أنابيب، مواسير، تشكيلات، سلك |

| قطر القضيب الدائري | 6mm - 300mm |

| سمك اللوحة | 3mm - 100mm |

| سمك الورقة | 0.5mm - 6mm |

| قطر الأنبوب الخارجي | 6mm - 219mm |

| قطر السلك | 0.1mm - 10mm |

| الطول | حتى 12 مترًا (أطوال مخصصة متاحة) |

| تشطيب السطح | مدرفل على الساخن، مدرفل على البارد، معالج حراري، مخلل، مصقول، مشغول |

| تحمل الأبعاد | ±0.1mm إلى ±0.5mm (حسب الشكل والحجم) |

| المعايير الدولية | ASTM B443، AMS 5599، UNS N06625، DIN 2.4856، EN 10216-5 |

| حالة المعالجة الحرارية | معالجة حرارية محلول، متقدم، تخفيف الإجهاد |

| شهادات الاختبار | شهادة اختبار المصنع (MTC)، شهادة اختبار المواد (3.1/3.2) |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing GH3625

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي المتقدم (VIM) وإعادة الصهر بالقوس الفراغي (VAR) لتحقيق تجانس كيميائي متفوق والقضاء على الشوائب، مما ينتج عنه GH3625 بخصائص ميكانيكية استثنائية ومقاومة محسّنة للإجهاد.

نظام شامل لمراقبة الجودة

نظام إدارة الجودة المتكامل لدينا يتميز بمراقبة العمليات في الوقت الحقيقي، وتحليل الطيف المتقدم، ومختبرات الاختبار الميكانيكي، وتتبع كامل من المواد الخام إلى المنتجات النهائية، مما يضمن جودة GH3625 المتسقة التي تتجاوز معايير الصناعة.

معالجة مخصصة والإمداد العالمي

MetalZenith تقدم إمكانيات تخصيص واسعة تشمل التشغيل الدقيق، تحسين معالجة الحرارة، ومعالجات السطح المتخصصة. تضمن شبكة التوزيع العالمية لدينا إمدادات موثوقة من GH3625 مع دعم فني واستشارات هندسية على مستوى العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات