20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

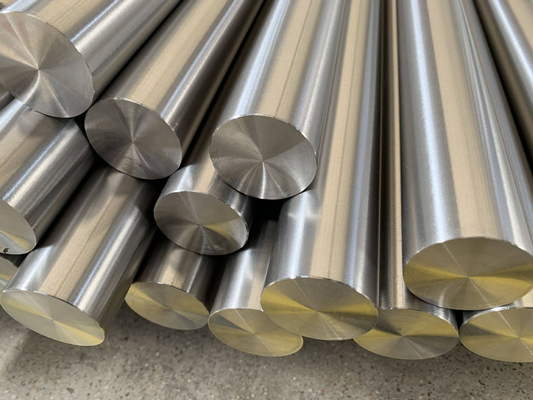

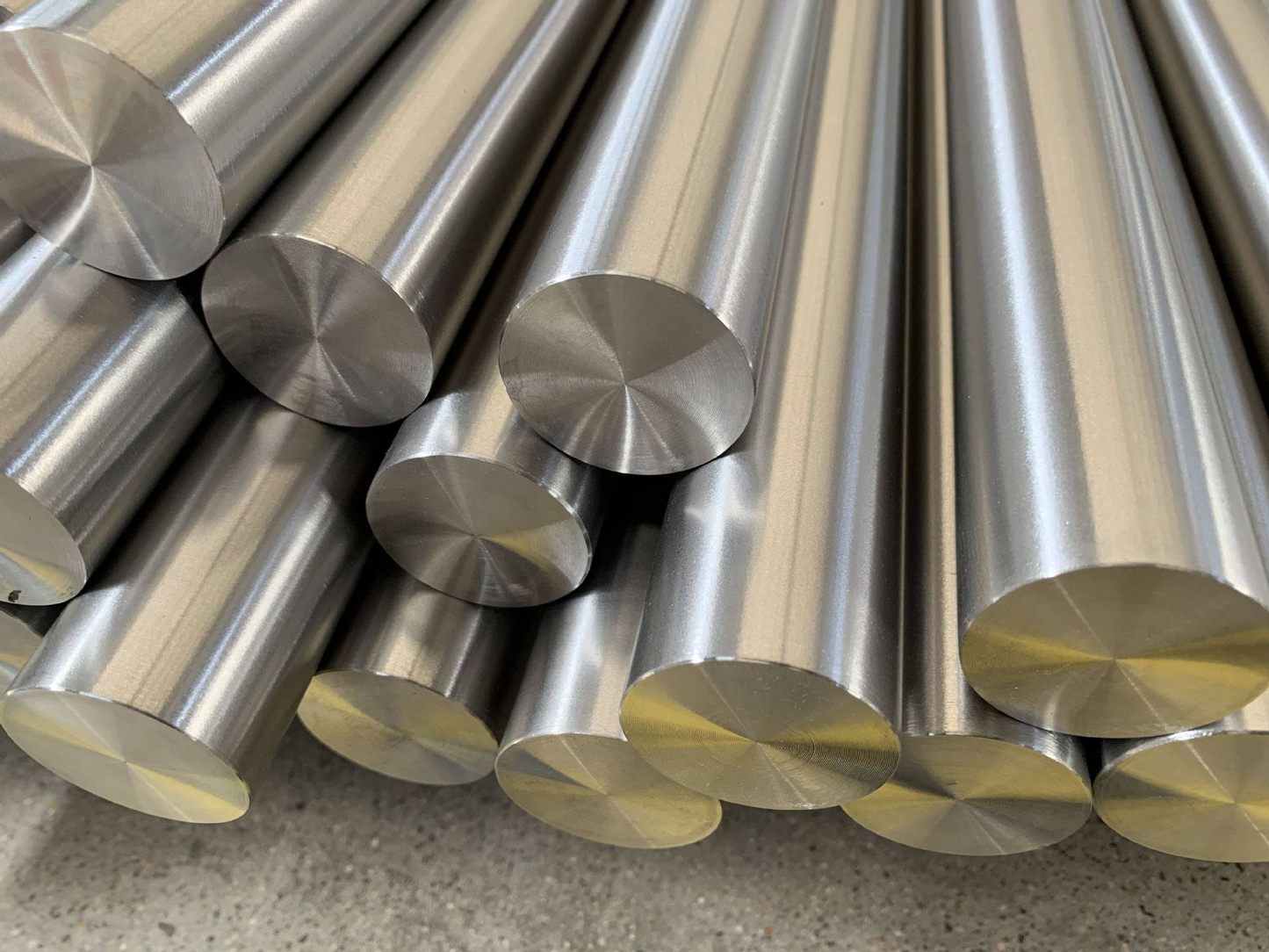

Product Overview

الخصائص المعدنية

UNS N06455 (Hastelloy C-4) هو سبيكة من النيكل والكروم والموليبدينوم الأوستنيتي مع مقاومة استثنائية للتآكل في كل من البيئات المؤكسدة والمختزلة. يتكون الميكروهيكل للسبيكة من مصفوفة أوستنيتية مستقرة مع مقاومة ممتازة للتآكل الناتج عن الإجهاد الناتج عن الكلور والتآكل الناتج عن الحفر.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية معالجة حرارية دقيقة عند 1065-1120°C تليها تبريد سريع لتحقيق مقاومة تآكل وخصائص ميكانيكية مثالية. تمنع معالجة الحرارة في جو محكم ترسيب الكربيد وتحافظ على خصائص السبيكة المقاومة للتآكل.

عملية التصنيع

تبدأ عملية التصنيع المتقدمة لدينا بالذوبان بالتحريض في الفراغ (VIM) تليها إعادة الذوبان بالقوس في الفراغ (VAR) لضمان التجانس الكيميائي والقضاء على الشوائب. يتم العمل الساخن بين 1150-900°C، تليها معالجة حرارية وحيدة وتبريد سريع. تتيح قدرات العمل البارد تعزيز خصائص القوة عند الحاجة.

معايير الجودة والاختبار

تخضع كل دفعة لاختبارات شاملة بما في ذلك التحليل الكيميائي عبر ICP-OES، والاختبار الميكانيكي وفقًا لمعايير ASTM، واختبار التآكل بين الحبيبات (ASTM A262)، والفحص غير المدمر. تحافظ MetalZenith على تتبع كامل من المواد الخام حتى الفحص النهائي، مما يضمن الامتثال لمعايير NACE MR0175/ISO 15156 لتطبيقات الخدمة الحامضية.

مقاومة التآكل

تظهر UNS N06455 مقاومة ممتازة لحمض الهيدروكلوريك، وحمض الكبريتيك، وحمض الفوسفوريك، والعديد من الأحماض العضوية. تحافظ السبيكة على أداء ممتاز في البيئات التي تحتوي على الكلور وتظهر مقاومة متفوقة للتآكل الناتج عن الإجهاد مقارنة بالفولاذ المقاوم للصدأ التقليدي.

🧪 Chemical Composition

| العنصر | نسبة الوزن % |

|---|---|

| نيكل (Ni) | التوازن |

| كروم (Cr) | 14.0-18.0 |

| موليبدينوم (Mo) | 14.0-17.0 |

| حديد (Fe) | ≤ 3.0 |

| تيتانيوم (Ti) | ≤ 0.70 |

| كربون (C) | ≤ 0.015 |

| منغنيز (Mn) | ≤ 1.0 |

| سيليكون (Si) | ≤ 0.08 |

| فوسفور (P) | ≤ 0.025 |

| كبريت (S) | ≤ 0.010 |

| كوبالت (Co) | ≤ 2.0 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (درجة حرارة الغرفة) | ≥ 690 MPa |

| قوة الخضوع (0.2% انزياح) | ≥ 310 MPa |

| التمدد في 50 مم | ≥ 45% |

| الصلابة (برينل) | ≤ 230 HB |

| الصلابة (روكويل ب) | ≤ 95 HRB |

| طاقة الصدمة (شاربي V-notch عند 20°C) | ≥ 150 J |

| قوة التعب (10&sup7; دورة) | 280 MPa |

| تقليل المساحة | ≥ 60% |

| معامل المرونة | 205 GPa |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.64 جرام/سم³ |

| نطاق نقطة الانصهار | 1320-1370°م |

| الموصلية الحرارية (عند 100°م) | 11.1 واط/م·ك |

| معامل التمدد الحراري (20-100°م) | 11.2×10-6/ك |

| السعة الحرارية النوعية | 420 جول/كجم·ك |

| المقاومة الكهربائية (عند 20°م) | 1.25 µΩ·م |

| نفاذية مغناطيسية | 1.002 (غير مغناطيسي) |

| درجة حرارة كوري | غير قابل للتطبيق |

| الانتشار الحراري (عند 100°م) | 3.06×10-6 م²/ث |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | قضبان دائرية، قضبان مسطحة، ألواح، صفائح، أنابيب، مواسير، تشكيلات، سلك |

| قطر القضيب الدائري | 6mm - 300mm |

| سمك اللوح | 3mm - 150mm |

| سمك الورقة | 0.5mm - 6mm |

| قطر الأنبوب الخارجي | 6mm - 219mm |

| الامتثال للمعايير | ASTM B575، ASME SB-575، UNS N06455، DIN 2.4610 |

| تشطيب السطح | مدرفل على الساخن، مدرفل على البارد، معالج حرارياً، مخلل، مصقول |

| تحمل الأبعاد | ±0.1mm إلى ±0.5mm (حسب الشكل والحجم) |

| خيارات الطول | الأطوال القياسية: 3م، 6م، 12م؛ أطوال مخصصة متاحة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing UNS N06455

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي (VIM) وإعادة الصهر بالقوس الفراغي (VAR) المتطورة لإنتاج UNS N06455 مع تجانس كيميائي استثنائي، وشوائب قليلة، وجودة معدنية فائقة تتجاوز المعايير الصناعية.

نظام شامل لمراقبة الجودة

تستخدم منشأتنا المعتمدة وفقًا لمعيار ISO 9001:2015 معدات اختبار متقدمة بما في ذلك مطياف ICP-OES وآلات الاختبار العالمية وأنظمة الفحص بالموجات فوق الصوتية لضمان أن كل دفعة تلبي مواصفات ASTM و ASME الصارمة مع وثائق تتبع كاملة.

معالجة مخصصة والإمداد العالمي

تقدم MetalZenith قدرات تخصيص واسعة تشمل المعالجات الحرارية المتخصصة، والتشغيل الدقيق، والأبعاد المخصصة. تضمن شبكتنا العالمية للتوزيع تسليمًا موثوقًا في جميع أنحاء العالم مع دعم فني شامل وخدمات استشارات هندسية.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات