20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

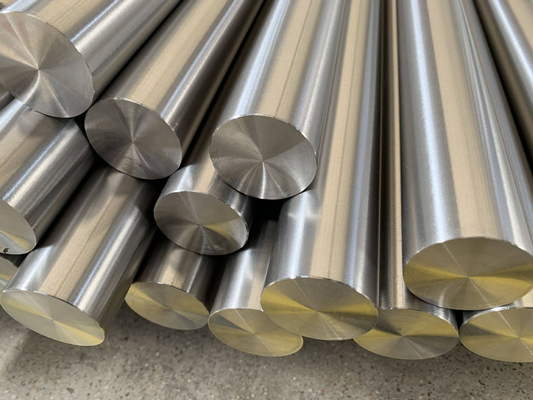

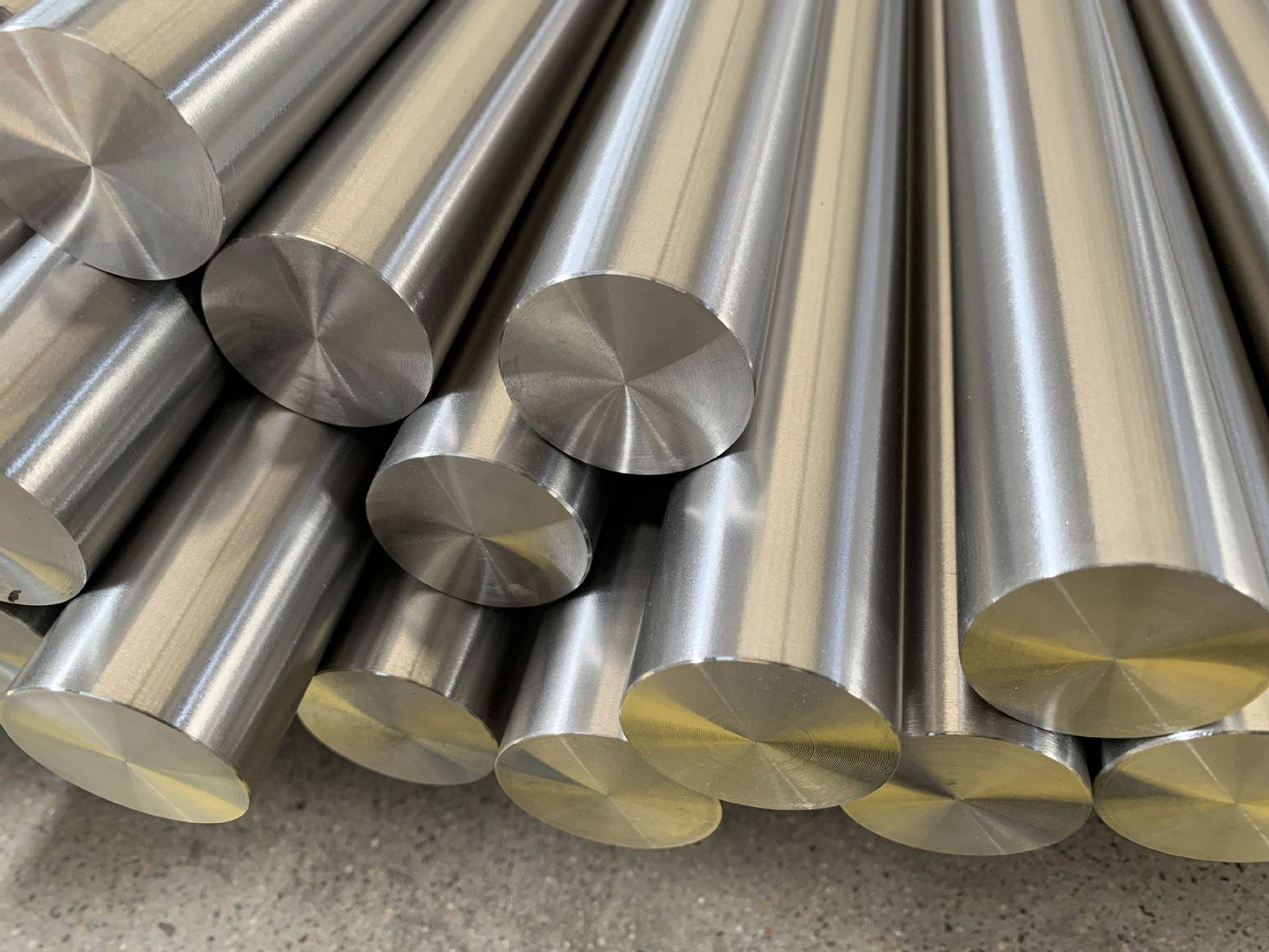

Product Overview

الخصائص المعدنية

UNS N07040 (Nimonic 75) هو سبيكة فائقة من النيكل والكروم مقواة بواسطة ترسبات غاما-برايم (Ni&sub3;Ti) المعالجة بالترسيب. تظهر السبيكة احتفاظًا استثنائيًا بقوة درجات الحرارة العالية، ومقاومة للأكسدة، واستقرار حراري يصل إلى 850°C. يتكون التركيب المجهري من مصفوفة أوستنيتية مع ترسبات غاما-برايم المتوزعة بشكل موحد التي توفر مقاومة فائقة للزحف وخصائص التعب الحراري.

عملية المعالجة الحرارية

تستخدم MetalZenith عملية معالجة حرارية دقيقة من مرحلتين: معالجة بالحرارة في محلول عند 1080°C لمدة 8 ساعات تليها تبريد بالهواء، ثم تصلب بالترسيب عند 700°C لمدة 16 ساعة مع تبريد بالهواء. تضمن هذه الدورة الحرارية المحسّنة أقصى ترسيب لمراحل التقوية مع الحفاظ على قابلية ممتازة للطرق والصلابة. تحافظ أفراننا التي يتم التحكم فيها بواسطة الكمبيوتر على تجانس درجة الحرارة ضمن ±5°C طوال دورة المعالجة.

تميز عملية التصنيع

تستخدم MetalZenith تقنية الصهر بالتحريض الفراغي المتقدم (VIM) تليها إعادة الصهر بالقوس الفراغي (VAR) لتحقيق نظافة استثنائية وتجانس. تشمل عملياتنا الميكانيكية الحرارية العمل الساخن المنضبط عند 1000-1150°C بمعدلات إجهاد دقيقة لتحسين بنية الحبوب والخصائص الميكانيكية. يتم تنفيذ عمليات العمل البارد مع دورات معالجة حرارية متوسطة لمنع تصلب العمل والحفاظ على دقة الأبعاد.

معايير الجودة والاختبار

تخضع كل منتج من UNS N07040 لاختبارات شاملة وفقًا لمعايير ASTM B637 و AMS 5382. تشمل بروتوكولات الجودة لدينا التحليل الكيميائي بواسطة مطيافية الانبعاث الضوئي، والاختبارات الميكانيكية عند درجات حرارة الغرفة ودرجات الحرارة المرتفعة، وفحص التركيب المجهري، والاختبار بالموجات فوق الصوتية، والتحقق من الأبعاد. يتم تزويد جميع المنتجات بتقارير اختبار معتمدة ووثائق تتبع كاملة تلبي متطلبات صناعة الطيران والطاقة النووية.

مقاومة التآكل والأداء البيئي

يوفر محتوى الكروم العالي مقاومة ممتازة للأكسدة في الهواء حتى 950°C ومقاومة فائقة للتأكسد والكربنة. تظهر السبيكة أداءً استثنائيًا في الأجواء المختزلة وتظهر مقاومة جيدة لتصدع التآكل الناتج عن الإجهاد في البيئات المحتوية على الكلوريد. تقوم MetalZenith بإجراء اختبارات تآكل متسارعة للتحقق من الأداء على المدى الطويل في بيئات التشغيل المحددة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| نيكل (Ni) | الرصيد (76.0 كحد أدنى) |

| كروم (Cr) | 18.0 - 21.0 |

| تيتانيوم (Ti) | 0.20 - 0.60 |

| كربون (C) | 0.08 - 0.15 |

| حديد (Fe) | ≤ 5.0 |

| منغنيز (Mn) | ≤ 1.0 |

| سيليكون (Si) | ≤ 1.0 |

| كبريت (S) | ≤ 0.015 |

| فوسفور (P) | ≤ 0.030 |

| نحاس (Cu) | ≤ 0.20 |

⚙️ Mechanical Properties

| الخاصية | القيمة | درجة حرارة الاختبار |

|---|---|---|

| قوة الشد | 850 - 1050 ميجا باسكال | درجة حرارة الغرفة |

| قوة الخضوع (0.2% انزياح) | ≥ 480 ميجا باسكال | درجة حرارة الغرفة |

| التمدد | ≥ 20% | درجة حرارة الغرفة |

| تقليل المساحة | ≥ 25% | درجة حرارة الغرفة |

| الصلابة (HRC) | 28 - 35 | درجة حرارة الغرفة |

| معامل يونغ | 210 جيجا باسكال | درجة حرارة الغرفة |

| قوة الشد | 620 ميجا باسكال | 700°م |

| قوة الخضوع | 380 ميجا باسكال | 700°م |

| طاقة الصدمة (شاربي V-notch) | ≥ 40 جول | درجة حرارة الغرفة |

| قوة التعب (10&sup7; دورة) | 400 ميجا باسكال | درجة حرارة الغرفة |

🔬 Physical Properties

| الخاصية | القيمة | نطاق درجة الحرارة |

|---|---|---|

| الكثافة | 8.19 جرام/سم³ | 20°م |

| نقطة الانصهار | 1390 - 1425°م | - |

| الموصلية الحرارية | 11.2 واط/م·ك | 20°م |

| الموصلية الحرارية | 18.5 واط/م·ك | 500°م |

| السعة الحرارية النوعية | 460 جول/كجم·ك | 20°م |

| معامل التمدد الحراري | 12.8×10-6/ك | 20-100°م |

| معامل التمدد الحراري | 15.2×10-6/ك | 20-700°م |

| المقاومة الكهربائية | 1.18 µΩ·م | 20°م |

| نفاذية مغناطيسية | بارامغناطيسي | درجة حرارة الغرفة |

| درجة حرارة كوري | غير قابل للتطبيق | - |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | شريط دائري، شريط مسطح، لوح، صفيحة، شريط، سلك، أنبوب، أنبوب، مخزون تزوير |

| قطر الشريط الدائري | 6mm - 300mm (±0.1mm tolerance) |

| سمك اللوح | 0.5mm - 6mm (±0.05mm tolerance) |

| سمك الصفيحة | 6mm - 100mm (±0.1mm tolerance) |

| قطر السلك | 0.1mm - 10mm (±0.02mm tolerance) |

| قطر الأنبوب الخارجي | 6mm - 200mm (سمك الجدار 0.5-20mm) |

| المعايير الدولية | ASTM B637, AMS 5382, BS HR 6, DIN 17742, EN 2.4630 |

| تشطيب السطح | مدرفل على الساخن، مسحوب على البارد، مؤكسد لامع، مخلل، مصقول، مصقول |

| حالة المعالجة الحرارية | مؤكسد محلول، مقوى بالتساقط، مخفف للإجهاد |

| خيارات الطول | قياسي: 3م، 6م؛ أطوال مخصصة متاحة حتى 12م |

| التغليف | صناديق خشبية، حزم فولاذية، تغليف واقي، تغليف تصدير |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing UNS N07040

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي المتطورة (VIM) وإعادة الصهر بالقوس الفراغي (VAR) لإنتاج UNS N07040 النقي للغاية مع الحد الأدنى من الشوائب وتجانس معدني فائق، مما يضمن أداءً استثنائيًا في درجات الحرارة العالية وموثوقية عالية.

تحكم دقيق في معالجة الحرارة

تتميز مرافق معالجة الحرارة المتطورة لدينا بأفران جوية تتحكم فيها الكمبيوتر مع ت uniformity دقيق في درجة الحرارة (±5°C) والتحكم في الجو، مما يعزز تصلب الترسيب لتحقيق أقصى قوة وخصائص ميكانيكية متسقة في جميع أنحاء المادة.

تكامل سلسلة التوريد الكامل

MetalZenith تقدم تخصيصًا شاملاً من المواد الخام إلى المكونات النهائية، بما في ذلك المعالجة الدقيقة، ومعالجات السطح، والتغليف. تضمن شبكتنا اللوجستية العالمية التسليم في الوقت المحدد مع تتبع كامل ووثائق الشهادات للتطبيقات الجوية والتطبيقات الحرجة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات