20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

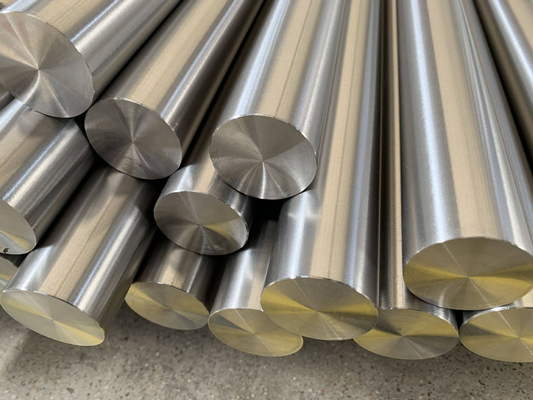

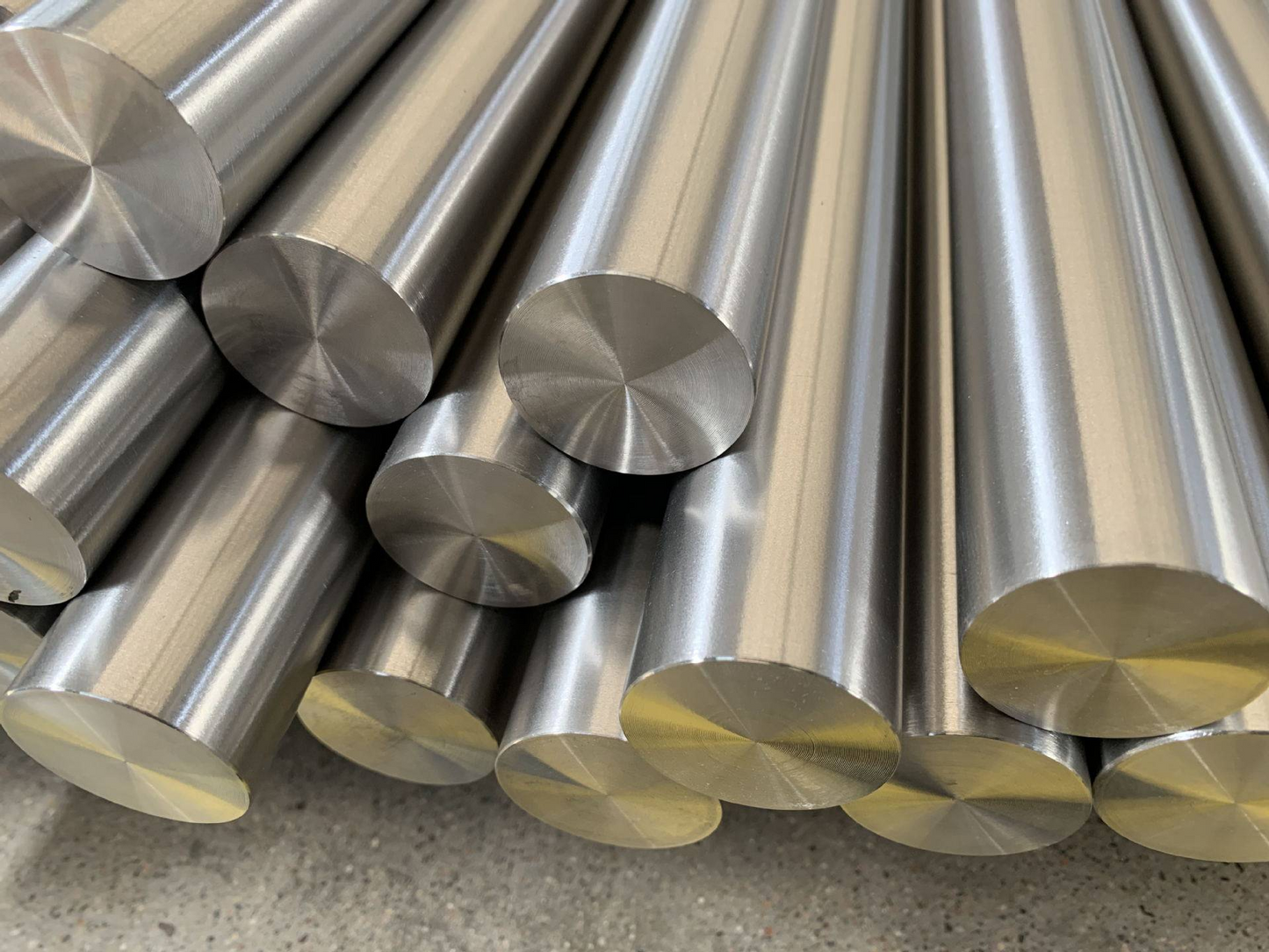

Product Overview

الخصائص المعدنية

UNS N07750 هو سبيكة فائقة من النيكل والكروم مقواة بواسطة ترسبات غاما-برايم (Ni3(Al,Ti)). تظهر السبيكة احتفاظًا استثنائيًا بقوة درجات الحرارة العالية، ومقاومة ممتازة للأكسدة، وخصائص تمزق زحف متفوقة تصل إلى 700°C. يوفر الإضافة المنضبطة للألمنيوم والتيتانيوم والنيوبيوم استجابة مثالية لتصلب الترسبات.

عملية المعالجة الحرارية

تستخدم MetalZenith دورات معالجة حرارية دقيقة تشمل التلدين في محلول عند 1095°C تليها تبريد منضبط وتقدم عند 704°C لمدة 20 ساعة. تعمل هذه العملية على تحسين حجم وتوزيع ترسبات غاما-برايم، مما يضمن خصائص ميكانيكية مستقرة وثبات أبعاد. تحافظ أفراننا التي يتم التحكم فيها بواسطة الكمبيوتر على تجانس درجة الحرارة ضمن ±5°C.

عملية التصنيع

تبدأ الإنتاج بالذوبان بالتحريض الفراغي (VIM) باستخدام مواد خام عالية النقاء، تليها إعادة الذوبان بالقوس الفراغي (VAR) لتحسين النظافة. يتم العمل الساخن ضمن نطاق درجات الحرارة من 1010-1175°C، مع التحكم الدقيق في نسب التخفيض لتحقيق هيكل حبيبي مثالي. يتم استخدام العمل البارد ودورات التلدين الوسيطة لأشكال المنتجات المحددة.

معايير الجودة والاختبار

تخضع جميع المواد لاختبارات شاملة تشمل التحليل الكيميائي بواسطة مطيافية الانبعاث الضوئي، والتحقق من الخصائص الميكانيكية وفقًا لمعايير ASTM، وفحص البنية المجهرية، والاختبار غير المدمر. يضمن الفحص بالموجات فوق الصوتية سلامة داخلية، بينما يتم التحقق من جودة السطح من خلال الاختبار البصري واختبار الاختراق. يتم الحفاظ على تتبع المواد بالكامل من الذوبان إلى تسليم المنتج النهائي.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.08 كحد أقصى |

| المنغنيز (Mn) | 1.00 كحد أقصى |

| السيليكون (Si) | 0.50 كحد أقصى |

| الفوسفور (P) | 0.015 كحد أقصى |

| الكبريت (S) | 0.015 كحد أقصى |

| الكروم (Cr) | 14.0 - 17.0 |

| النيكل (Ni) | 70.0 كحد أدنى |

| الحديد (Fe) | 5.0 - 9.0 |

| الألمنيوم (Al) | 0.40 - 1.00 |

| التيتانيوم (Ti) | 2.25 - 2.75 |

| النيوبوم (Nb) | 0.70 - 1.20 |

| النحاس (Cu) | 0.50 كحد أقصى |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (درجة حرارة الغرفة) | 1275 MPa min |

| قوة الخضوع (0.2% انزياح) | 1035 MPa min |

| التمدد في 50 مم | 15% min |

| تخفيض المساحة | 15% min |

| الصلابة (روكويل C) | 35-45 HRC |

| قوة الصدمة (شاربي V-notch) | 41 J min |

| قوة التعب (10&sup7; دورة) | 620 MPa |

| تمزق الزحف (649°C، 100 ساعة) | 690 MPa |

| معامل يونغ | 214 GPa |

| معامل القص | 85 GPa |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.25 g/cm³ |

| نقطة الانصهار | 1393-1430°C |

| الموصلية الحرارية (20°C) | 11.2 W/m·K |

| الموصلية الحرارية (649°C) | 19.5 W/m·K |

| التوسع الحراري (20-100°C) | 11.2×10-6/K |

| التوسع الحراري (20-649°C) | 13.3×10-6/K |

| السعة الحرارية (20°C) | 435 J/kg·K |

| المقاومة الكهربائية (20°C) | 1.18 µΩ·m |

| نفاذية مغناطيسية | 1.004 (مغناطيسي قليلاً) |

| درجة حرارة كوري | -73°C |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | بار دائري، بار مسطح، لوح، صفيحة، أنبوب، ماسورة، سلك، مخزون تزوير |

| قطر البار الدائري | 6mm - 300mm |

| سمك اللوح | 0.5mm - 6mm |

| سمك الصفيحة | 6mm - 100mm |

| نطاق OD للأنبوب | 6mm - 219mm |

| الامتثال للمعايير | ASTM B637، AMS 5542، AMS 5667، UNS N07750 |

| تشطيب السطح | مدرفل على الساخن، مسحوب على البارد، مخلل، مصقول، مشغول |

| تحمل الأبعاد | ±0.1mm إلى ±0.5mm (حسب الشكل والحجم) |

| خيارات الطول | أطوال قياسية 3م، 6م، 12م أو مقطعة حسب الطول |

| حالة المعالجة الحرارية | مخلوط محلول، مُعمر، أو محدد من قبل العميل |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing UNS N07750

تكنولوجيا الصهر بالفراغ المتقدمة

MetalZenith تستخدم عمليات الصهر بالتحريض الفراغي المتقدمة (VIM) وإعادة الصهر بالقوس الفراغي (VAR) لتحقيق نقاء استثنائي للمواد وتجانس كيميائي. إن صهرنا في جو محكم يزيل الشوائب ويضمن ترسيب غاما-برايم المتسق لأداء مثالي في درجات الحرارة العالية.

تحكم دقيق في معالجة الحرارة

تقدم مرافق المعالجة الحرارية التي تتحكم فيها الكمبيوتر تحكمًا دقيقًا في درجة الحرارة والوقت لعمليات التلدين بالحلول والشيخوخة. يضمن ذلك تقوية الترسيب المثلى، وخصائص ميكانيكية متسقة، واستقرار أبعاد عبر جميع أشكال وأحجام المنتجات.

اختبار شامل وشهادة

تخضع كل دفعة لرقابة جودة صارمة تشمل التحليل الكيميائي، والاختبارات الميكانيكية، وفحص البنية المجهرية. تضمن شهادات AS9100D و NADCAP لدينا الامتثال لمعايير الطيران، بينما تدعم تتبع المواد الكامل متطلبات التطبيقات الحرجة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات