20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

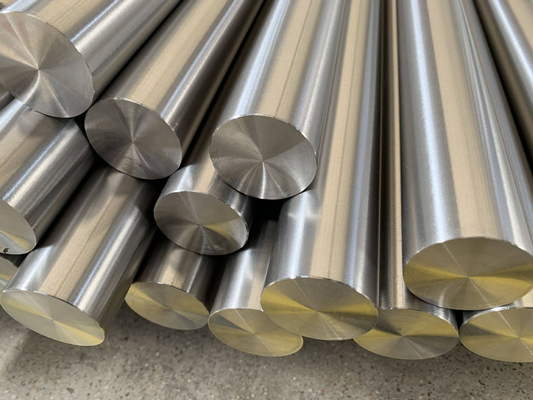

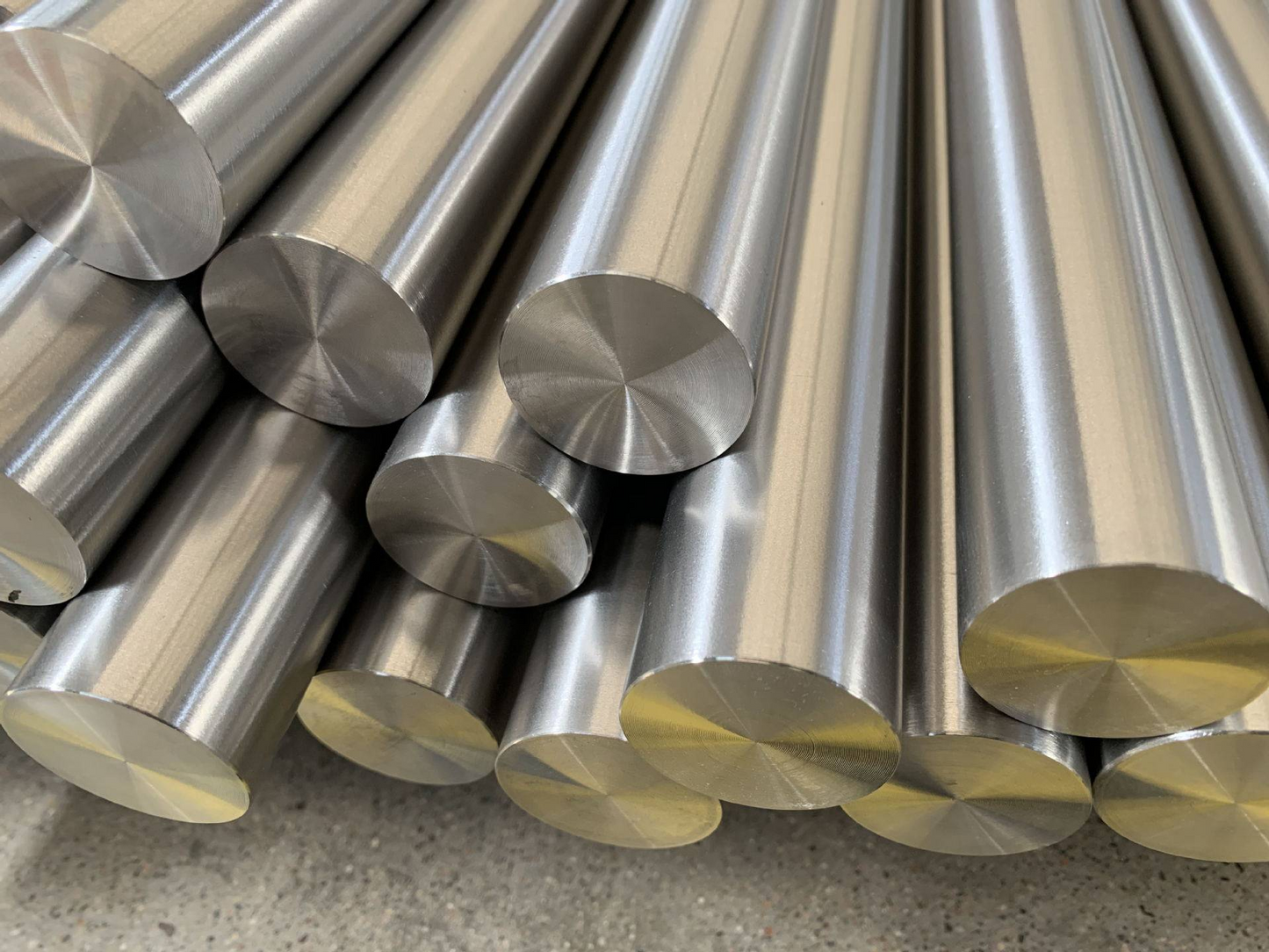

Product Overview

الخصائص المعدنية

يظهر UNS N06022 هيكل أوستنيتي مكعب مركزي الواجهة مع استقرار استثنائي عبر نطاق واسع من درجات الحرارة. يوفر المزيج الفريد من الكروم والموليبدينوم والتنغستن مقاومة ممتازة للتآكل المحلي، بما في ذلك التآكل النقطي، وتآكل الشقوق، وتصدع التآكل الناتج عن الإجهاد. تضمن عملية التصلب المتحكم بها من MetalZenith توزيعًا مثاليًا للكربيد وكيمياء حدود الحبوب.

عملية المعالجة الحرارية

تتم عملية التلدين القياسية عند 1120°C (2050°F) تليها تبريد سريع لمنع ترسيب الكربيد. تستخدم MetalZenith أفران جوية متحكم بها بدقة مع اتساق درجة حرارة ±5°C. تزيل معالجة السطح بعد المعالجة الحرارية الأكسدة مع الحفاظ على دقة الأبعاد. قد يتم تطبيق علاجات تخفيف الإجهاد عند 870°C للمكونات الملحومة.

عملية التصنيع

تبدأ الإنتاج بصهر التحريض الفراغي للمواد الخام الممتازة، تليها إعادة صهر الكهرومغناطيسية لتحسين النظافة. تستخدم عمليات العمل الساخن معدات تشكيل ودرفلة متحكم بها بواسطة الكمبيوتر مع الحفاظ على ملفات درجة حرارة دقيقة. تشمل قدرات العمل البارد الدرفلة الدقيقة، والسحب، وعمليات التشكيل مع دورات تلدين متوسطة حسب الحاجة.

معايير الجودة والاختبار

تحافظ MetalZenith على أنظمة جودة شاملة متوافقة مع متطلبات ISO 9001:2015 وAS9100D وNADCAP. تشمل بروتوكولات الاختبار التحليل الكيميائي عبر ICP-OES، والتحقق من الخصائص الميكانيكية، والفحص بالموجات فوق الصوتية، وفحص السائل النافذ، واختبارات التآكل المتخصصة بما في ذلك طرق ASTM G48 وG28. ترافق جميع الشحنات وثائق تتبع المواد والشهادات الكاملة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| نيكل (Ni) | الرصيد (56.0 كحد أدنى) |

| كروم (Cr) | 20.0 - 22.5 |

| موليبدينوم (Mo) | 12.5 - 14.5 |

| تنجستن (W) | 2.5 - 3.5 |

| حديد (Fe) | 2.0 - 6.0 |

| كوبالت (Co) | ≤ 2.5 |

| كربون (C) | ≤ 0.015 |

| منغنيز (Mn) | ≤ 0.50 |

| سيليكون (Si) | ≤ 0.08 |

| فوسفور (P) | ≤ 0.02 |

| كبريت (S) | ≤ 0.010 |

| فاناديوم (V) | ≤ 0.35 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد (درجة حرارة الغرفة) | ≥ 690 MPa (100 ksi) |

| قوة العائد (0.2% انحراف) | ≥ 310 MPa (45 ksi) |

| التمدد في 50 مم | ≥ 45% |

| الصلابة (برينيل) | ≤ 223 HB |

| الصلابة (روكويل ب) | ≤ 96 HRB |

| طاقة الصدمة (شاربي V-notch) | ≥ 203 J (150 ft-lbs) |

| قوة التعب (10&sup7; دورة) | 310 MPa |

| معامل المرونة | 206 GPa (30×10&sup6; psi) |

| نسبة بواسون | 0.31 |

| معامل القص | 81.4 GPa |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 8.69 g/cm³ (0.314 lb/in³) |

| نقطة الانصهار | 1370-1400°C (2500-2550°F) |

| الموصلية الحرارية (100°C) | 11.1 W/m·K (6.4 Btu/hr·ft·°F) |

| التوسع الحراري (20-100°C) | 12.4×10-6/K (6.9×10-6/°F) |

| السعة الحرارية النوعية | 394 J/kg·K (0.094 Btu/lb·°F) |

| المقاومة الكهربائية (20°C) | 1.18 µΩ·m |

| نفاذية مغناطيسية | 1.002 (غير مغناطيسي أساساً) |

| درجة حرارة كوري | غير قابل للتطبيق (بارامغناطيسي) |

| الانتشار الحراري (100°C) | 3.24×10-6 m²/s |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | لوح، ورقة، شريط، قضيب، سلك، أنبوب، ماسورة، تزوير |

| سمك اللوح | 6mm - 200mm (0.25' - 8') |

| سمك الورقة | 0.5mm - 6mm (0.02' - 0.25') |

| قطر القضيب | 6mm - 300mm (0.25' - 12') |

| نطاق OD للأنبوب | 6mm - 610mm (0.25' - 24') |

| الامتثال للمعايير | ASTM B575, B619, B622, B626, ASME SB-575, EN 2.4602 |

| تشطيبات السطح | تشطيب مطحنة، مخلل، مصقول، مصقول |

| تحمل الأبعاد | معيار ASTM أو مخصص حسب المواصفات |

| خيارات الطول | أطوال قياسية أو قطع حسب الحجم |

| الحالة | تم تسخينها بالحل (1120°C + تبريد سريع) |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing UNS N06022

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي المتطورة (VIM) وإعادة الصهر بالتيار الكهربائي (ESR) لإنتاج UNS N06022 مع تجانس كيميائي استثنائي ومحتوى حد أدنى من الشوائب، مما يضمن مقاومة فائقة للتآكل وخصائص ميكانيكية ممتازة.

أنظمة مراقبة الجودة الشاملة

نظام إدارة الجودة المتكامل لدينا يتميز بمراقبة العمليات في الوقت الفعلي، وتحليل الطيف المتقدم، وبروتوكولات اختبار ميكانيكية شاملة. كل دفعة تخضع لاختبارات تآكل صارمة وتحليل للميكروهيكل لضمان أداء متسق.

معالجة مخصصة والإمداد العالمي

MetalZenith تقدم قدرات تخصيص واسعة تشمل المعالجات الحرارية المتخصصة، والتشغيل الدقيق، وتعديلات السبائك المخصصة. تضمن شبكة التوزيع العالمية لدينا تسليم موثوق في جميع أنحاء العالم مع تتبع كامل للمواد ووثائق الشهادات.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات