20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

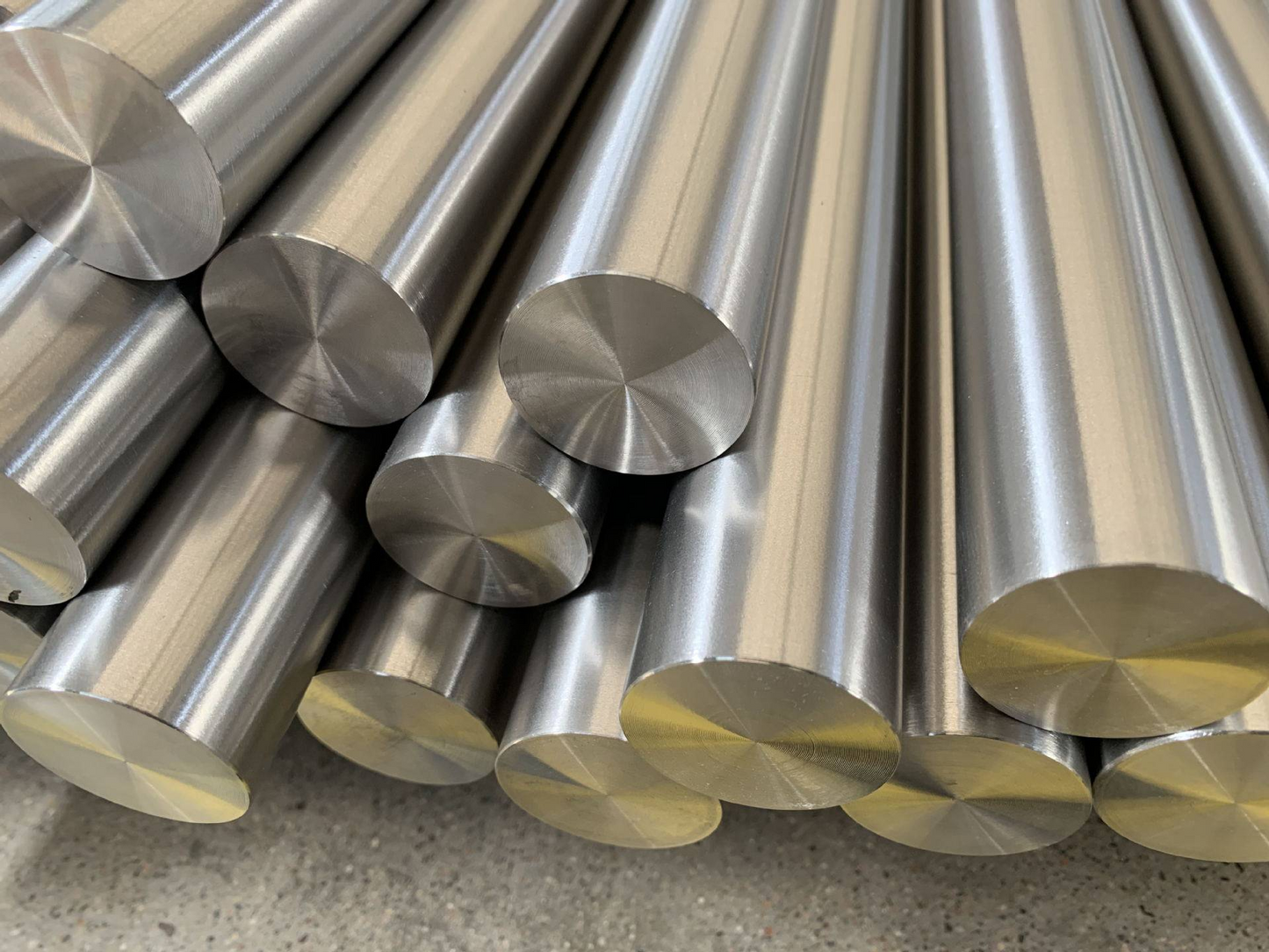

Product Overview

Metallurgical Characteristics

AH36 marine steel features a fine-grained ferrite-pearlite microstructure achieved through controlled rolling and normalizing heat treatment. The steel's composition includes microalloying elements such as niobium, vanadium, and titanium, which provide grain refinement and precipitation strengthening. This results in an optimal balance of strength, toughness, and weldability essential for marine applications.

Heat Treatment Process

MetalZenith employs a precise normalizing process where the steel is heated to 900-950°C and air-cooled to achieve uniform microstructure and stress relief. Our controlled cooling rates ensure consistent mechanical properties throughout the plate thickness. The normalizing treatment enhances grain refinement and eliminates residual stresses from hot rolling.

Manufacturing Process

Our production process begins with electric arc furnace steelmaking followed by ladle refining for precise chemistry control. Continuous casting produces high-quality slabs with minimal segregation. Controlled rolling at specific temperature ranges optimizes grain structure, while inline cooling systems ensure uniform properties. Advanced process control systems monitor temperature, reduction ratios, and cooling rates throughout production.

Quality Standards and Testing

Every heat of AH36 steel undergoes comprehensive testing including chemical analysis, tensile testing, Charpy impact testing at specified temperatures, and ultrasonic examination. MetalZenith maintains ISO 9001:2015 quality management systems and holds certifications from major classification societies. Our quality control procedures ensure full traceability from raw materials to finished products, with detailed mill test certificates provided for each shipment.

Welding and Fabrication

AH36 steel exhibits excellent weldability with most conventional welding processes including SMAW, GMAW, FCAW, and SAW. The controlled carbon equivalent ensures minimal preheating requirements and reduces the risk of cold cracking. Post-weld heat treatment is typically not required for most applications, making it ideal for shipyard fabrication processes.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | 0.90 - 1.60 |

| Silicon (Si) | 0.10 - 0.50 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Aluminum (Al) | ≥ 0.015 |

| Niobium (Nb) | 0.02 - 0.05 |

| Vanadium (V) | 0.05 - 0.10 |

| Titanium (Ti) | 0.02 - 0.05 |

| Nitrogen (N) | ≤ 0.009 |

| Copper (Cu) | ≤ 0.35 |

| Chromium (Cr) | ≤ 0.20 |

| Nickel (Ni) | ≤ 0.40 |

| Molybdenum (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (ReH) | ≥ 355 MPa |

| Tensile Strength (Rm) | 490 - 630 MPa |

| Elongation (A5) | ≥ 22% |

| Impact Energy (KV at 0°C) | ≥ 34 J |

| Impact Energy (KV at -20°C) | ≥ 24 J |

| Brinell Hardness (HB) | 150 - 200 |

| Young's Modulus | 210 GPa |

| Poisson's Ratio | 0.30 |

| Fatigue Limit (107 cycles) | 160 MPa |

| Fracture Toughness (K1C) | 80 - 120 MPa·m1/2 |

| Reduction of Area | ≥ 50% |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (at 20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.8 mm²/s |

| Emissivity (oxidized surface) | 0.79 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Plates, Sheets, Bars, Sections |

| Plate Thickness Range | 6 - 150 mm |

| Plate Width Range | 1500 - 4000 mm |

| Plate Length Range | 6000 - 18000 mm |

| Surface Finish | Hot Rolled, Normalized, Shot Blasted |

| Edge Condition | Mill Edge, Trimmed Edge, Flame Cut |

| Dimensional Tolerance | EN 10029 Class A/B |

| Flatness Tolerance | ≤ 5 mm/m |

| Standards Compliance | ASTM A131, EN 10225, JIS G3106 |

| Classification Society Approval | ABS, DNV-GL, LR, BV, CCS |

| Heat Treatment Condition | Normalized (N) |

| Impact Test Temperature | 0°C, -20°C, -40°C |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing AH36

Advanced Controlled Rolling Technology

MetalZenith employs sophisticated controlled rolling and normalizing processes with precise temperature control to achieve optimal grain refinement and superior mechanical properties. Our thermomechanical processing ensures consistent strength, toughness, and weldability throughout the steel structure.

Comprehensive Quality Testing Systems

Our integrated quality control laboratory features advanced testing equipment including optical emission spectrometers, universal testing machines, Charpy impact testers, and ultrasonic flaw detection systems. Every batch undergoes rigorous chemical analysis, mechanical testing, and non-destructive evaluation to guarantee compliance with marine steel standards.

Flexible Production and Global Supply

MetalZenith offers extensive customization capabilities including various plate thicknesses, cut-to-size services, and special surface treatments. Our global distribution network and strategic inventory management ensure reliable supply chain support with competitive lead times for marine construction projects worldwide.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

สอบถามด่วน

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications