20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

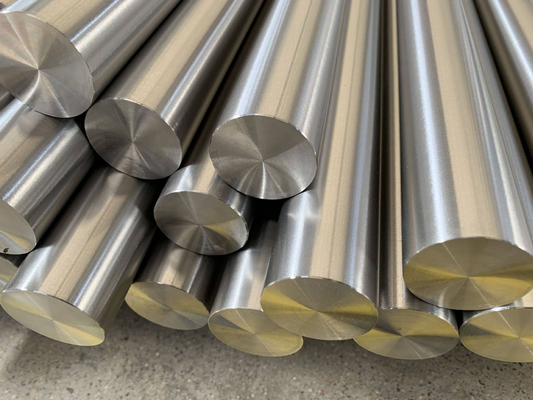

Product Overview

Metallurgical Characteristics

EH32 steel features a fine-grained ferritic-pearlitic microstructure achieved through controlled thermomechanical processing. The steel's enhanced strength is derived from grain refinement, solid solution strengthening, and controlled precipitation of microalloying elements such as niobium and vanadium.

Heat Treatment Process

MetalZenith employs advanced controlled rolling techniques followed by accelerated cooling to achieve optimal mechanical properties. The steel is typically supplied in the normalized or thermomechanically controlled processed (TMCP) condition, with finishing temperatures between 850-950°C and controlled cooling rates to ensure proper microstructural development.

Manufacturing Process

Our EH32 steel production utilizes electric arc furnace melting with secondary refining processes including ladle furnace treatment and vacuum degassing. The steel undergoes continuous casting followed by controlled rolling in our state-of-the-art hot strip mill with precise temperature control and accelerated cooling systems.

Quality Standards & Testing

Every batch of EH32 steel undergoes comprehensive testing including chemical analysis, tensile testing, impact testing at specified temperatures, hardness measurement, and ultrasonic inspection. MetalZenith maintains ISO 9001:2015 certification and follows marine classification society requirements for material traceability and quality documentation.

Weldability & Fabrication

EH32 steel exhibits excellent weldability with carbon equivalent values typically below 0.40%. The steel can be welded using conventional arc welding processes including SMAW, GMAW, and SAW. Preheating may be required for thick sections, typically 100-150°C depending on thickness and ambient conditions.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | 0.90 - 1.60 |

| Silicon (Si) | 0.10 - 0.50 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Chromium (Cr) | ≤ 0.20 |

| Nickel (Ni) | ≤ 0.40 |

| Molybdenum (Mo) | ≤ 0.08 |

| Copper (Cu) | ≤ 0.35 |

| Aluminum (Al) | ≥ 0.015 |

| Niobium (Nb) | ≤ 0.05 |

| Vanadium (V) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.02 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (ReH) | ≥ 315 MPa |

| Tensile Strength (Rm) | 440 - 590 MPa |

| Elongation (A5) | ≥ 22% |

| Impact Energy (KV at -20°C) | ≥ 34 J |

| Impact Energy (KV at -40°C) | ≥ 24 J |

| Brinell Hardness (HB) | 150 - 220 |

| Young's Modulus | 210 GPa |

| Shear Modulus | 81 GPa |

| Poisson's Ratio | 0.30 |

| Fatigue Limit (107 cycles) | 200 MPa |

| Fracture Toughness (KIC) | 150 MPa·m1/2 |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.7 mm²/s |

| Coefficient of Linear Expansion (0-100°C) | 11.5×10-6/K |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Plates, Sheets, Bars, Profiles, Forgings |

| Plate Thickness Range | 6 - 150 mm |

| Sheet Thickness Range | 2 - 6 mm |

| Width Range | 1000 - 4000 mm |

| Length Range | 2000 - 18000 mm |

| Standards Compliance | EN 10225, ASTM A131, JIS G3136, GB/T 712 |

| Surface Finish | Hot Rolled, Normalized, Shot Blasted |

| Edge Condition | Mill Edge, Trimmed Edge, Slit Edge |

| Thickness Tolerance | ± 0.3 mm (t ≤ 40mm), ± 0.05t (t > 40mm) |

| Width Tolerance | ± 10 mm |

| Length Tolerance | ± 25 mm |

| Flatness | ≤ 5 mm/m |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EH32

Advanced Thermomechanical Processing

MetalZenith employs cutting-edge controlled rolling and accelerated cooling technologies to achieve optimal microstructural refinement in EH32 steel, resulting in superior mechanical properties and enhanced low-temperature toughness for marine applications.

Comprehensive Marine Certification

Our EH32 steel production facility maintains certifications from all major marine classification societies including ABS, DNV-GL, Lloyd's Register, and Bureau Veritas, ensuring full compliance with international maritime standards and regulations.

Custom Marine Solutions

MetalZenith offers extensive customization capabilities for EH32 steel products, including specialized heat treatments, precise dimensional tolerances, and tailored mechanical properties to meet specific marine engineering requirements and vessel design specifications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications