20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

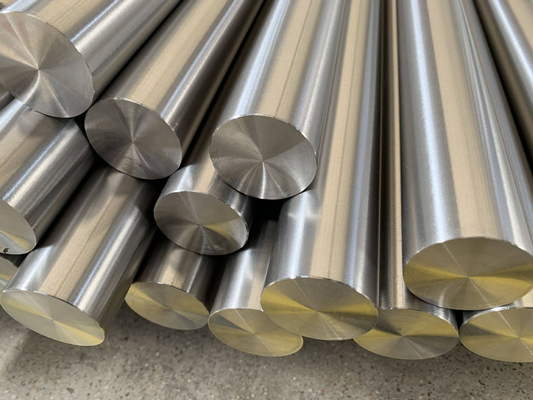

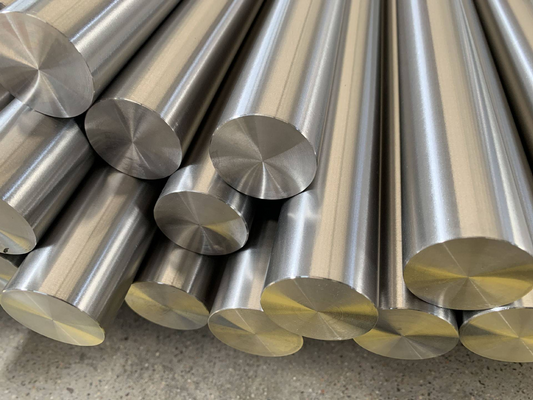

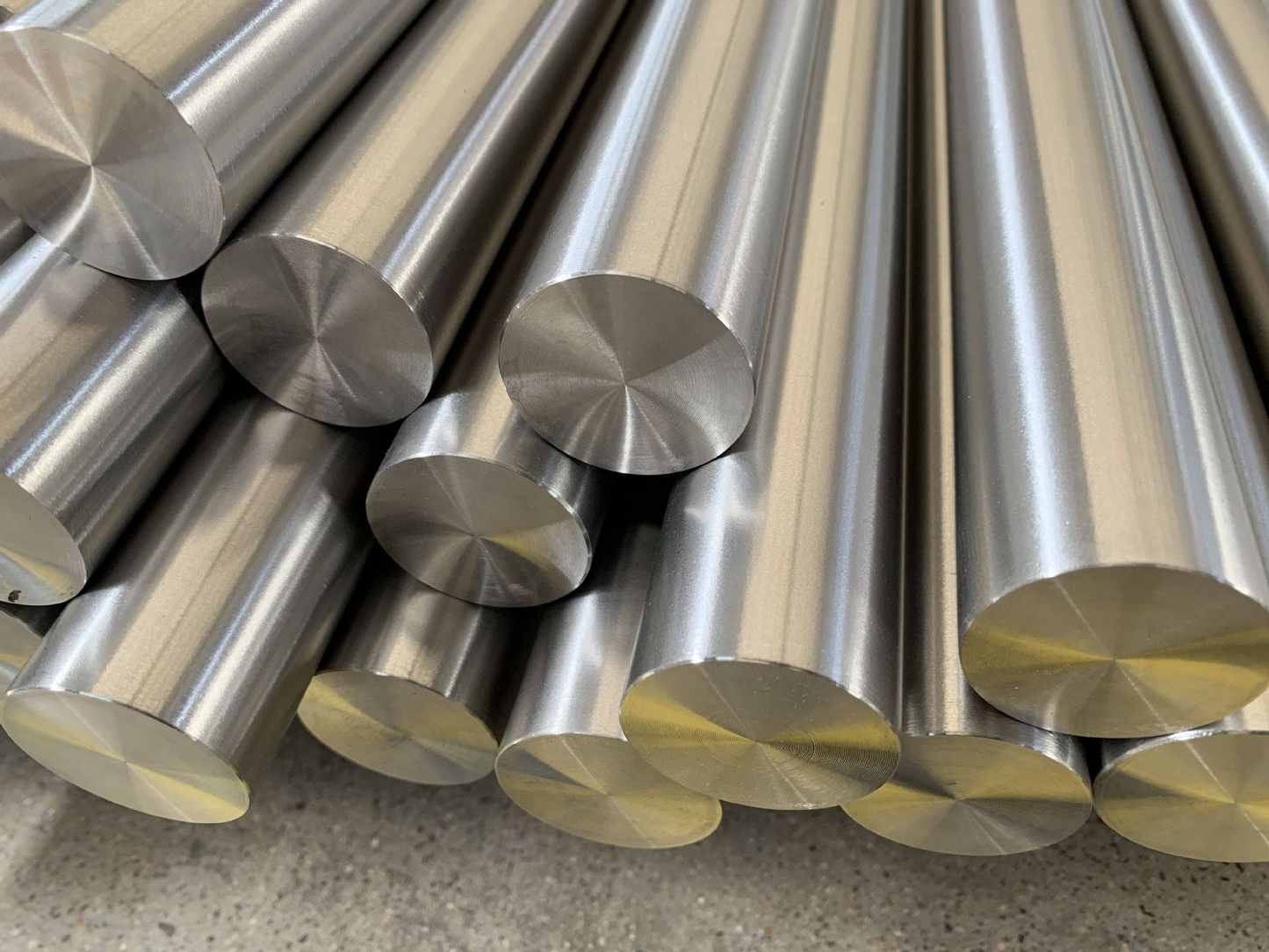

Product Overview

Металлургические характеристики

UNS N07718 является никель-хромовым суперсплавом с осаждением, укрепленным гамма-примесами (Ni&sub3;(Al,Ti)) и гамма-двойными примесами (Ni&sub3;Nb). Уникальное сочетание добавок ниобия и титана обеспечивает исключительное сохранение прочности при повышенных температурах до 700°C, в то время как содержание хрома гарантирует превосходную стойкость к окислению и коррозии в агрессивных средах.

Процесс термообработки

MetalZenith использует точный двухступенчатый процесс старения после раствора отжига при 980°C. Процесс старения состоит из нагрева до 720°C в течение 8 часов, последующего охлаждения в печи до 620°C, выдержки в течение 8 часов, а затем воздушного охлаждения. Эта контролируемая последовательность осаждения оптимизирует образование укрепляющих фаз, сохраняя при этом пластичность и прочность.

Совершенство производственного процесса

Наш интегрированный производственный процесс начинается с вакуумного индукционного плавления (VIM), за которым следует вакуумное дуговое переплавление (VAR) или электрошлаковое переплавление (ESR) для обеспечения исключительной чистоты и однородности. Операции горячей обработки выполняются в строго контролируемых температурных диапазонах (1010-1180°C) для достижения оптимальной зернистой структуры и механических свойств. Возможности холодной обработки обеспечивают точный контроль размеров и улучшенное качество поверхности.

Стандарты качества и тестирование

Каждая партия продукции проходит комплексное тестирование, включая химический анализ с помощью оптической эмиссионной спектроскопии, проверку механических свойств через испытания на растяжение и ударные испытания, а также микроструктурное исследование. Методы неразрушающего контроля, включая ультразвуковую инспекцию, тестирование с использованием жидких проникающих веществ и магнитно-частицкую инспекцию, обеспечивают внутреннюю целостность. Наша система управления качеством соответствует требованиям ISO 9001:2015, AS9100D и NADCAP, обеспечивая полную прослеживаемость от сырьевых материалов до готовой продукции.

Техническая поддержка и инженерные услуги

MetalZenith предоставляет комплексную техническую поддержку, включая рекомендации по выбору материалов, оптимизацию термообработки, разработку сварочных процедур и услуги по анализу отказов. Наши металлургические инженеры тесно сотрудничают с клиентами для разработки индивидуальных решений для конкретных приложений, обеспечивая оптимальную производительность в условиях жесткой эксплуатации. Полные пакеты документации включают сертификаты материалов, отчеты о тестировании и записи о прослеживаемости, соответствующие требованиям аэрокосмической и ядерной промышленности.

🧪 Chemical Composition

| Элемент | Вес % |

|---|---|

| Никель (Ni) | 50.0 - 55.0 |

| Хром (Cr) | 17.0 - 21.0 |

| Железо (Fe) | Остальное |

| Ниобий + Тантал (Nb+Ta) | 4.75 - 5.50 |

| Молибден (Mo) | 2.80 - 3.30 |

| Титан (Ti) | 0.65 - 1.15 |

| Алюминий (Al) | 0.20 - 0.80 |

| Углерод (C) | ≤ 0.08 |

| Марганец (Mn) | ≤ 0.35 |

| Кремний (Si) | ≤ 0.35 |

| Фосфор (P) | ≤ 0.015 |

| Сера (S) | ≤ 0.015 |

| Медь (Cu) | ≤ 0.30 |

| Кобальт (Co) | ≤ 1.00 |

| Бор (B) | ≤ 0.006 |

⚙️ Mechanical Properties

| Свойство | Значение | Условие |

|---|---|---|

| Устойчивость к растяжению | ≥ 1275 MPa | Комнатная температура |

| Предел текучести (0.2% смещение) | ≥ 1035 MPa | Комнатная температура |

| Удлинение | ≥ 12% | Комнатная температура |

| Снижение площади | ≥ 15% | Комнатная температура |

| Твердость | 331-444 HB | Состояние после старения |

| Энергия удара (Charpy V-notch) | ≥ 27 J | Комнатная температура |

| Устойчивость к усталости (10&sup7; циклов) | 620 MPa | Комнатная температура |

| Модуль Юнга | 200 GPa | Комнатная температура |

| Сдвиговой модуль | 77 GPa | Комнатная температура |

| Коэффициент Пуассона | 0.30 | Комнатная температура |

| Устойчивость к растяжению при 650°C | ≥ 1035 MPa | Высокая температура |

| Предел текучести при 650°C | ≥ 825 MPa | Высокая температура |

🔬 Physical Properties

| Свойство | Значение | Температура |

|---|---|---|

| Плотность | 8.19 g/cm³ | 20°C |

| Температура плавления | 1260-1336°C | - |

| Теплопроводность | 11.2 W/m·K | 20°C |

| Теплопроводность | 18.6 W/m·K | 650°C |

| Коэффициент теплового расширения | 13.0×10-6/K | 20-100°C |

| Коэффициент теплового расширения | 14.4×10-6/K | 20-650°C |

| Удельная теплоемкость | 435 J/kg·K | 20°C |

| Электрическое сопротивление | 1.25 µΩ·m | 20°C |

| Магнитная проницаемость | 1.0011 | Комнатная температура |

| Температура Кюри | -112°C | - |

| Тепловая диффузия | 3.15×10-6 m²/s | 20°C |

| Максимальная рабочая температура | 700°C | Непрерывно |

📏 Product Specifications

| Спецификация | Доступные варианты | Стандарты |

|---|---|---|

| Формы продукта | Круглые прутки, квадратные прутки, плоские прутки, пластины, листы, кованые изделия, трубы, трубы | ASTM B637, AMS 5662/5663 |

| Диаметр круглого прутка | 6mm - 500mm | ASTM B637 |

| Размер квадратного прутка | 10mm - 200mm | ASTM B637 |

| Толщина пластины | 3mm - 150mm | ASTM B670 |

| Толщина листа | 0.5mm - 6mm | ASTM B670 |

| Внешний диаметр трубы | 6mm - 200mm | ASTM B983 |

| Обработка поверхности | Горячекатаный, холоднокатаный, обработанный, полированный, травленный | По спецификации клиента |

| Условия термообработки | Растворный отжиг, старение, растворный отжиг + старение | AMS 5662/5663 |

| Размерные допуски | ±0.1mm до ±3mm в зависимости от размера | Стандарты ASTM |

| Длина | До 12 метров (доступны индивидуальные длины) | Спецификация клиента |

| Международные стандарты | ASTM, AMS, UNS, EN, DIN, JIS, GB | Несколько сертификатов |

| Сертификаты испытаний | Сертификат испытаний завода, сертификат материала, сертификат инспекции | EN 10204 3.1/3.2 |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing UNS N07718

Совершенная технология вакуумного плавления

MetalZenith использует современные процессы вакуумного индукционного плавления (VIM), за которыми следует вакуумное дуговое переплавление (VAR), что обеспечивает исключительную чистоту материала, однородность и устранение включений. Наши процессы в контролируемой атмосфере гарантируют постоянный химический состав и превосходные металлургические свойства на протяжении всего ассортимента продукции.

Точные возможности термической обработки

Наши компьютеризированные установки для термической обработки обеспечивают точный контроль температуры и времени для оптимального осаждения твердых растворов UNS N07718. Современная печная технология с равномерными зонами нагрева гарантирует стабильные механические свойства и развитие микроструктуры, соответствуя самым строгим требованиям в области аэрокосмической и ядерной техники.

Полная интеграция цепочки поставок

MetalZenith предлагает комплексные услуги по настройке от обработки сырья до готовых компонентов. Наша интегрированная цепочка поставок включает прецизионную обработку, обработку поверхностей и специализированную упаковку для критических приложений. Глобальная логистическая сеть обеспечивает своевременную доставку с полной документацией по отслеживанию и пакетами сертификатов.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты