20 лет опыта | 1000+ партнеров по брендам | Полная настройка

У нас 20 лет опыта в отрасли, мы сотрудничаем с более чем 1,000 брендами и поддерживаем любые потребности в настройке.

Technical Specifications

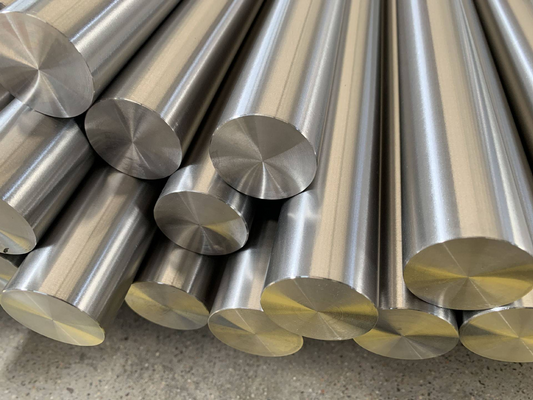

Product Overview

Металлургические характеристики

SA 414 G - это высокопрочная низколегированная конструкционная сталь с мелкозернистой ферритно-перлитной микроструктурой. Контролируемое добавление меди, никеля и хрома обеспечивает повышенную атмосферную коррозионную стойкость и улучшенные механические свойства. Оптимизированное содержание углерода обеспечивает отличную свариваемость при сохранении высоких прочностных характеристик, необходимых для конструкционных применений.

Процесс термообработки

MetalZenith использует контролируемую прокатку при температурах от 850 до 950°C, за которой следует воздушное охлаждение или нормализация при 900-920°C. Этот процесс обеспечивает оптимальное упрочнение зерна и равномерные механические свойства по всему сечению. Контролируемая скорость охлаждения предотвращает чрезмерное закаливание при сохранении желаемых уровней прочности.

Процесс производства

Наше производство стали SA 414 G использует плавку в электродуговой печи с последующими процессами вторичной переработки, включая металлургию в ковше и вакуумное дегазирование. Технология непрерывного литья MetalZenith обеспечивает однородный химический состав и минимальную сегрегацию, за которой следует прецизионная горячая прокатка с компьютерным управлением процессом для обеспечения стабильных механических свойств.

Тестирование структурного качества

Комплексные протоколы тестирования включают оценку производительности сварки с использованием стандартных процедур, оценку формуемости через испытания на изгиб, определение прочности на усталость при циклической нагрузке и тестирование атмосферной коррозионной стойкости в смоделированных экологических условиях. Все испытания соответствуют требованиям ASTM A414 и лучшим практикам отрасли.

Соображения по инженерному применению

Для строительства сооружений SA 414 G обеспечивает отличные соотношения прочности и веса, а также сейсмостойкость. В мостостроении его превосходная усталостная стойкость и свариваемость позволяют создавать сложные конструкции соединений. Для производства машин материал обеспечивает надежную работу при динамических нагрузках. В строительстве транспортных средств он обеспечивает стойкость к ударам и структурную целостность. Общие инженерные приложения выигрывают от его универсальных возможностей обработки и стабильного качества.

🧪 Chemical Composition

| Элемент | Состав (%) |

|---|---|

| Углерод (C) | 0.15 - 0.21 |

| Марганец (Mn) | 0.80 - 1.25 |

| Кремний (Si) | 0.15 - 0.40 |

| Фосфор (P) | ≤ 0.035 |

| Сера (S) | ≤ 0.040 |

| Медь (Cu) | 0.20 - 0.50 |

| Никель (Ni) | 0.25 - 0.50 |

| Хром (Cr) | 0.40 - 0.65 |

⚙️ Mechanical Properties

| Свойство | Значение |

|---|---|

| Предельная прочность (МПа) | ≥ 350 |

| Тянущая прочность (МПа) | 485 - 620 |

| Удлинение (%) | ≥ 18 |

| Энергия удара при 0°C (Дж) | ≥ 27 |

| Твердость (HB) | 140 - 190 |

| Прочность на усталость (МПа) | 160 - 180 |

🔬 Physical Properties

| Свойство | Значение |

|---|---|

| Плотность (г/см3) | 7.85 |

| Температура плавления (°C) | 1510 - 1540 |

| Теплопроводность (Вт/м·К) | 50.2 |

| Тепловое расширение (×10??/К) | 11.8 |

| Модуль упругости (ГПа) | 200 |

| Коэффициент Пуассона | 0.27 - 0.30 |

📏 Product Specifications

| Спецификация | Детали |

|---|---|

| Доступные формы | Плиты, Листы, Балки, Каналы, Уголки, Бруски |

| Диапазон толщины | 8 - 150мм |

| Диапазон ширины | 1200 - 3500мм |

| Диапазон длины | 6000 - 15000мм |

| Соответствие стандартам | ASTM A414 Grade G, AISC, AWS D1.1 |

| Условия термообработки | Нормализованный или Как прокатано |

| Обработка поверхности | Мельничный масштаб, Стреляный, Кислотный |

Давайте создадим успех для вашего проекта

Профессиональная команда, премиум-продукты, полный сервис - успех вашего проекта является нашей миссией

Our Advantages in Processing Сталь SA 414 G

Совершенная контролируемая прокатка технологий

MetalZenith использует современные контролируемые процессы прокатки с точным контролем температуры и оптимизированными графиками редукции для достижения превосходного упрочнения зерна в стали SA 414 G. Наши передовые термомеханические процессы обеспечивают постоянные механические свойства и улучшенную структурную целостность по всему сечению материала.

Комплексное испытание структурной производительности

Наш сталь SA 414 G проходит обширные испытательные протоколы, включая оценку сварочной производительности, оценку формуемости, испытания на усталостную прочность и анализ атмосферной коррозионной стойкости. Современные испытательные мощности MetalZenith обеспечивают оптимальную производительность в требовательных структурных приложениях с долгосрочной надежностью.

Пользовательская обработка и инженерная поддержка

MetalZenith предоставляет комплексные услуги по индивидуальной обработке, включая прецизионную резку, формовку и термообработку, адаптированные к конкретным структурным требованиям. Наша техническая команда предлагает экспертные консультации по выбору материалов, проектированию соединений и методам изготовления для оптимизации производительности в строительных и инфраструктурных проектах.

ВАШ НАДЕЖНЫЙ СТАЛЬ

ПАРТНЕР ПО ПРОИЗВОДСТВУ

Быстрый запрос

Отрасли, которые мы обслуживаем

Профессиональные стальные решения для основных отраслей

Квалификации и сертификаты