20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

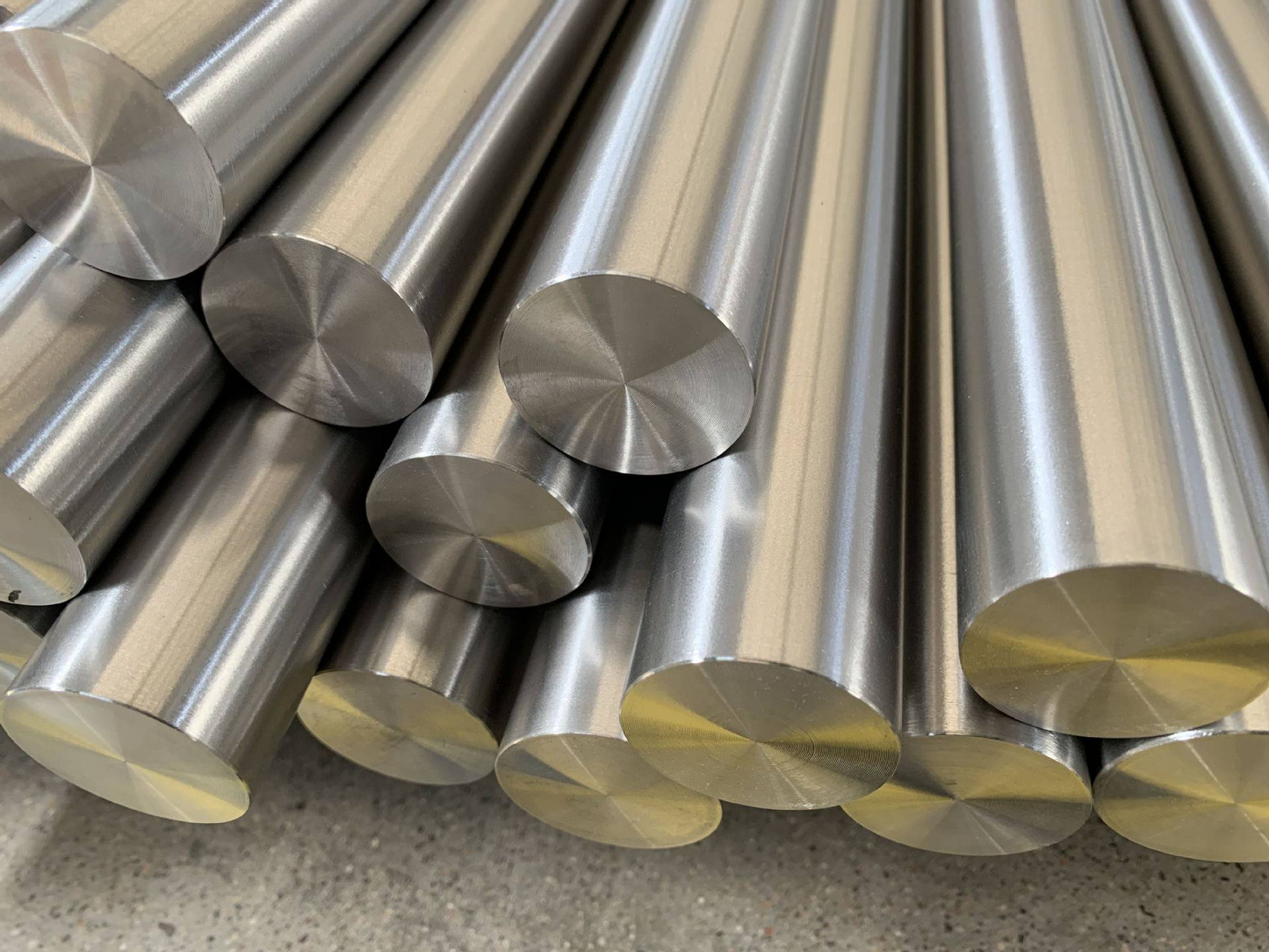

Product Overview

Características Metalúrgicas

S7 é um aço ferramenta resistente a choques de cromo-tungstênio-molibdênio projetado para aplicações que exigem excepcional tenacidade e resistência ao impacto. A composição única da liga cria uma estrutura martensítica de grão fino com carbonetos bem distribuídos que proporcionam excelentes propriedades de absorção de choque, mantendo uma boa resistência ao desgaste.

Processo de Tratamento Térmico

O tratamento térmico otimizado da MetalZenith envolve pré-aquecimento a 650-700°C, seguido de austenitização a 940-980°C em atmosfera protetora. O resfriamento é realizado em óleo ou ar, dependendo do tamanho da seção, seguido de revenimento a 150-650°C para alcançar os níveis de dureza desejados. Nossas taxas de resfriamento controladas garantem mínima distorção e microestrutura ideal.

Processo de Fabricação

A produção começa com a fusão em forno de arco elétrico usando matérias-primas de alta qualidade, seguida de refino em panela e desgasificação a vácuo. O aço passa por remeltagem eletroslag (ESR) para maior limpeza e homogeneidade. A forjamento a quente e o resfriamento controlado otimizam a estrutura do grão, enquanto a usinagem de precisão e os tratamentos de superfície atendem às especificações exatas dos clientes.

Padrões de Qualidade

Todos os produtos de aço S7 estão em conformidade com padrões internacionais, incluindo ASTM A681, DIN 1.2355 e JIS SKS3. Os testes abrangentes incluem análise química por espectroscopia de emissão óptica, verificação de propriedades mecânicas, inspeção ultrassônica para integridade interna e verificação dimensional. Nosso sistema de gestão da qualidade ISO 9001:2015 garante excelência consistente do produto e total rastreabilidade desde as matérias-primas até os produtos acabados.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.45 - 0.55 |

| Manganês (Mn) | 0.20 - 0.80 |

| Silício (Si) | 0.20 - 1.00 |

| Fósforo (P) | ≤ 0.030 |

| Enxofre (S) | ≤ 0.030 |

| Cromo (Cr) | 3.00 - 3.50 |

| Molibdênio (Mo) | 1.30 - 1.80 |

| Tungstênio (W) | 1.30 - 1.80 |

| Níquel (Ni) | ≤ 0.30 |

| Cobre (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração (Recozido) | 690 - 790 MPa |

| Resistência de Escoamento (Recozido) | 415 - 485 MPa |

| Alongamento (Recozido) | 22 - 28% |

| Redução de Área (Recozido) | 45 - 55% |

| Dureza (Recozido) | 197 - 229 HB |

| Dureza (Endurecido e Temperado) | 54 - 58 HRC |

| Energia de Impacto (Charpy V-notch) | 40 - 60 J |

| Limite de Fadiga | 550 - 650 MPa |

| Módulo de Elasticidade | 210 GPa |

| Razão de Poisson | 0.27 - 0.30 |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.80 g/cm³ |

| Ponto de Fusão | 1480 - 1520°C |

| Condutividade Térmica (20°C) | 28 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 11.5×10-6/K |

| Coeficiente de Expansão Térmica (20-200°C) | 12.2×10-6/K |

| Capacidade Calorífica Específica | 460 J/kg·K |

| Resistividade Elétrica (20°C) | 0.65 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 760°C |

| Difusividade Térmica | 7.8×10-6 m²/s |

📏 Product Specifications

| Especificação | Detalhes |

|---|---|

| Formas Disponíveis | Barras redondas, barras planas, chapas, blocos, forjados |

| Diâmetro da Barra Redonda | 6 - 500 mm |

| Espessura da Barra Plana | 10 - 200 mm |

| Espessura da Chapa | 20 - 300 mm |

| Comprimento Padrão | 3000 - 6000 mm (comprimentos personalizados disponíveis) |

| Acabamento de Superfície | Laminado a quente, recozido, usinado, retificado |

| Tolerância Dimensional | ±0.1 mm (usinado com precisão) |

| Conformidade com Normas | ASTM A681, DIN 1.2355, JIS SKS3 |

| Condição de Tratamento Térmico | Recozido, endurecido e temperado (opcional) |

| Certificação de Qualidade | Certificado de teste de fábrica, análise química, propriedades mecânicas |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing S7

Tecnologia Avançada de Derretimento a Vácuo

MetalZenith emprega processos de fusão por indução a vácuo (VIM) e remeltagem por eletroescória (ESR) de última geração para produzir aço S7 com excepcional limpeza e homogeneidade química. Nosso processamento em atmosfera controlada elimina inclusões prejudiciais e garante uma estrutura de grão consistente para resistência ao choque e confiabilidade ideais.

Controle de Tratamento Térmico de Precisão

Nossos protocolos de tratamento térmico proprietários utilizam fornos controlados por computador com monitoramento de temperatura preciso e controle de atmosfera. Isso garante uma distribuição ideal de carbonetos e um equilíbrio de dureza da matriz, proporcionando propriedades mecânicas consistentes e maximizando as características de resistência ao choque do aço S7.

Serviços de Personalização Abrangentes

MetalZenith oferece amplas capacidades de personalização, incluindo usinagem de precisão, ciclos de tratamento térmico especializados e dimensões personalizadas. Nossa rede global de cadeia de suprimentos garante entrega rápida em todo o mundo, enquanto nossa equipe de suporte técnico fornece consultoria especializada para requisitos específicos de aplicação e otimização de desempenho.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações