20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

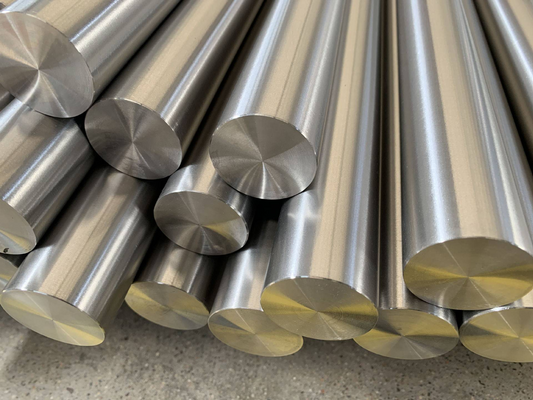

Product Overview

Características Metalúrgicas

O GB Q690 é um aço estrutural de baixo carbono e alta resistência, apresentando uma microestrutura de grão fino obtida através de laminação controlada e processos de resfriamento acelerado. O aço exibe uma microestrutura predominantemente ferrítica-bainítica com precipitados de carboneto dispersos, proporcionando uma excelente combinação de resistência, tenacidade e soldabilidade. A adição controlada de elementos microaleantes, como vanádio, nióbio e titânio, possibilita o endurecimento por precipitação e o refino de grão.

Tratamento Térmico & Processamento

A MetalZenith emprega Processamento Termomecânico Controlado (TMCP) avançado como a principal rota de produção para o aço GB Q690. O processo envolve laminação controlada a temperaturas entre 850-950°C, seguida de resfriamento acelerado para alcançar propriedades mecânicas ótimas. Opções alternativas de tratamento térmico incluem normalização a 900-950°C ou têmpera e revenimento com austenitização a 900-930°C, têmpera em água ou óleo, e revenimento a 580-650°C, dependendo dos requisitos específicos da aplicação.

Excelência no Processo de Fabricação

Nosso processo de fabricação começa com a seleção cuidadosa de matérias-primas e cálculo preciso da carga para alcançar a química alvo. O aço é fundido em fornos de arco elétrico com refino secundário através de forno de panela e desgasificação a vácuo para garantir baixo teor de inclusões e limpeza ideal. A fundição contínua produz lingotes e chapas de alta qualidade, que são posteriormente processados em nossos modernos laminadores equipados com sistemas avançados de controle de processo para controle preciso de temperatura e deformação.

Normas de Qualidade & Certificações

O aço GB Q690 fabricado pela MetalZenith está em conformidade com a norma GB/T 1591-2018 e especificações internacionais equivalentes, incluindo EN 10025-6 S690QL e ASTM A514. Nosso sistema de gestão da qualidade é certificado pela ISO 9001:2015, e mantemos certificações adicionais, incluindo ISO 14001 para gestão ambiental e OHSAS 18001 para saúde e segurança ocupacional. Cada lote de produção passa por testes abrangentes, incluindo análise química por espectroscopia de emissão óptica, verificação de propriedades mecânicas, teste ultrassônico para integridade interna e inspeção dimensional.

Diretrizes de Soldagem & Fabricação

O aço GB Q690 apresenta excelente soldabilidade quando os procedimentos adequados são seguidos. O pré-aquecimento a 100-150°C é recomendado para seções com mais de 25mm de espessura. Consumíveis de soldagem de baixo hidrogênio devem ser utilizados, mantendo as temperaturas entre passes abaixo de 250°C. O tratamento térmico pós-soldagem pode ser benéfico para alívio de tensões em aplicações críticas. O aço pode ser facilmente moldado, usinado e fabricado usando métodos convencionais, embora forças de corte mais altas possam ser necessárias devido ao seu alto nível de resistência.

🧪 Chemical Composition

| Elemento | Conteúdo (%) | Propósito |

|---|---|---|

| Carbono (C) | ≤ 0.18 | Resistência e dureza |

| Manganês (Mn) | 1.00-1.70 | Resistência e temperabilidade |

| Silício (Si) | 0.15-0.60 | Desoxidação e resistência |

| Fósforo (P) | ≤ 0.025 | Impureza controlada |

| Enxofre (S) | ≤ 0.015 | Impureza controlada |

| Cromo (Cr) | 0.30-1.50 | Temperabilidade e resistência |

| Níquel (Ni) | 0.30-2.00 | Tenacidade e resistência |

| Molibdênio (Mo) | 0.15-0.70 | Temperabilidade e resistência ao fluência |

| Vanádio (V) | 0.02-0.12 | Refinamento de grão |

| Nióbio (Nb) | 0.015-0.060 | Endurecimento por precipitação |

| Titânio (Ti) | 0.006-0.050 | Refinamento de grão |

| Alumínio (Al) | ≥ 0.015 | Desoxidação e refinamento de grão |

⚙️ Mechanical Properties

| Propriedade | Valor | Norma de Teste |

|---|---|---|

| Limite de Esforço (ReL) | ≥ 690 MPa | GB/T 228.1 |

| Limite de Tração (Rm) | 770-940 MPa | GB/T 228.1 |

| Alongamento (A50) | ≥ 14% | GB/T 228.1 |

| Energia de Impacto (KV2) a 20°C | ≥ 47 J | GB/T 229 |

| Energia de Impacto (KV2) a -20°C | ≥ 34 J | GB/T 229 |

| Energia de Impacto (KV2) a -40°C | ≥ 27 J | GB/T 229 |

| Dureza Brinell (HBW) | 230-280 | GB/T 231.1 |

| Módulo de Young | 210 GPa | GB/T 22315 |

| Razão de Poisson | 0.30 | GB/T 22315 |

| Limite de Fadiga (10&sup7; ciclos) | 350 MPa | GB/T 4337 |

| Tenacidade à Fratura (KIC) | 120 MPa·m1/2 | GB/T 4161 |

| Teste de Dobra a Frio (180°) | 3t (t = espessura) | GB/T 232 |

🔬 Physical Properties

| Propriedade | Valor | Temperatura/Condições |

|---|---|---|

| Densidade | 7.85 g/cm³ | 20°C |

| Ponto de Fusão | 1510°C | Temperatura solidus |

| Condutividade Térmica | 54 W/m·K | 20°C |

| Coeficiente de Expansão Térmica | 12×10-6/K | 20-100°C |

| Capacidade Calorífica Específica | 500 J/kg·K | 20°C |

| Resistividade Elétrica | 0.16 µΩ·m | 20°C |

| Permeabilidade Magnética | Ferromagnético | Temperatura ambiente |

| Temperatura de Curie | 770°C | Transição magnética |

| Difusividade Térmica | 13.7×10-6 m²/s | 20°C |

| Emissividade | 0.85 | Superfície oxidada |

| Velocidade do Som (Longitudinal) | 5900 m/s | 20°C |

| Velocidade do Som (Transversal) | 3200 m/s | 20°C |

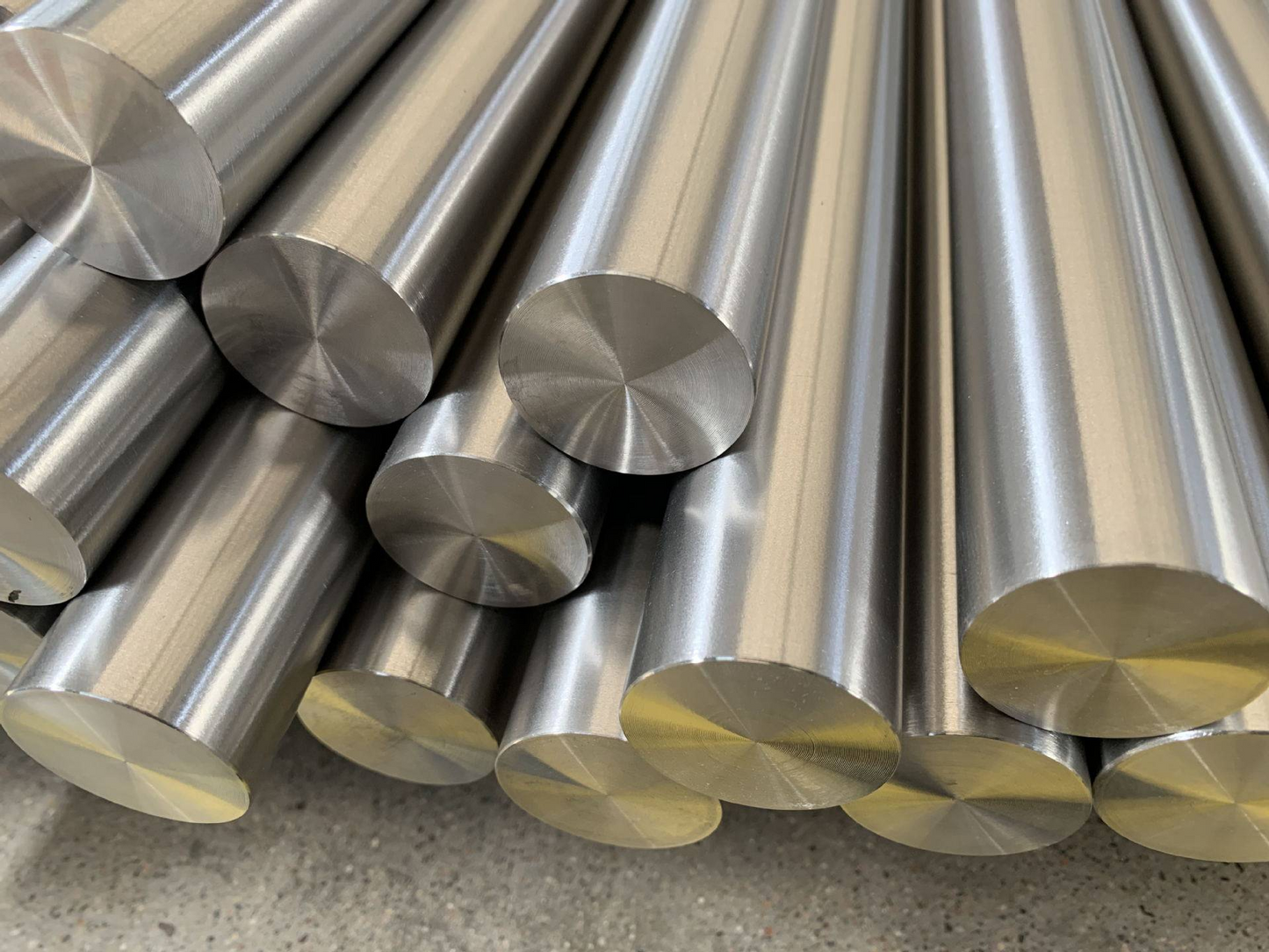

📏 Product Specifications

| Especificação | Opções Disponíveis | Normas |

|---|---|---|

| Formas de Produto | Placas, Folhas, Barras, Tubos, Forjados, Formas personalizadas | GB/T 1591, GB/T 3274 |

| Espessura da Placa | 8-100 mm | GB/T 3274 |

| Largura da Placa | 1500-4200 mm | GB/T 3274 |

| Comprimento da Placa | 6000-18000 mm | GB/T 3274 |

| Diâmetro da Barra | 16-300 mm | GB/T 702 |

| Diâmetro Externo do Tubo | 25-600 mm | GB/T 8162 |

| Espessura da Parede do Tubo | 3-50 mm | GB/T 8162 |

| Acabamento de Superfície | Laminado a quente, Normalizado, Temperado e Revenido, Jateado, Desincrustado | GB/T 1591 |

| Tolerância Dimensional | Classe A, B, C conforme normas GB | GB/T 3274, GB/T 702 |

| Tolerância de Planicidade | ≤ 5 mm/m | GB/T 3274 |

| Condição da Borda | Borda de moinho, Borda aparada, Borda cortada | GB/T 3274 |

| Condição de Entrega | TMCP, N (Normalizado), Q+T (Temperado e Revenido) | GB/T 1591 |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing GB Q690

Tecnologia TMCP Avançada

MetalZenith emprega tecnologia de Processamento Termomecânico Controlado (TMCP) de ponta com controle de temperatura preciso e cronogramas de laminação otimizados para alcançar um refinamento de grão superior e propriedades mecânicas aprimoradas na produção de aço GB Q690.

Controle de Qualidade Abrangente

Nosso sistema integrado de gestão da qualidade apresenta monitoramento em tempo real da composição química, testes mecânicos automatizados e equipamentos avançados de ensaio não destrutivo para garantir que cada lote de aço GB Q690 atenda aos mais altos padrões de qualidade com total rastreabilidade.

Capacidades de Personalização Flexíveis

MetalZenith oferece amplas opções de personalização para o aço GB Q690, incluindo várias formas de produtos, dimensões, tratamentos de superfície e requisitos de processamento especiais, apoiados por nossa rede global de cadeia de suprimentos e serviços de engenharia técnica.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações