20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

Product Overview

Características Metalúrgicas

GB 42CrMo é um aço de baixa liga com cromo e molibdênio como principais elementos de liga, proporcionando excelente endurecimento e propriedades de endurecimento total. O teor de cromo melhora a resistência à corrosão e o endurecimento, enquanto o molibdênio melhora a resistência a altas temperaturas e reduz a fragilidade ao revenido. O teor equilibrado de carbono garante uma relação ideal entre resistência e tenacidade.

Processo de Tratamento Térmico

O processo de tratamento térmico da MetalZenith envolve austenitização a 850-870°C seguida de resfriamento em óleo para alcançar a estrutura martensítica. O revenido é realizado a 550-650°C dependendo dos níveis de dureza requeridos. Nossos fornos de atmosfera controlada garantem aquecimento uniforme e previnem a descarbonização. O alívio de tensões a 600-650°C é recomendado para componentes usinados.

Excelência no Processo de Fabricação

Nosso processo de produção começa com a seleção cuidadosa de matérias-primas e fusão em forno de arco elétrico com controle preciso da adição de ligas. O refino secundário através de forno de panela e desgasificação a vácuo remove impurezas e garante homogeneidade química. A fundição contínua produz lingotes de alta qualidade, seguidos de laminação controlada para alcançar as propriedades mecânicas e a estrutura de grão desejadas.

Padrões de Qualidade e Testes

A MetalZenith mantém protocolos rigorosos de controle de qualidade, incluindo análise química por espectroscopia de emissão óptica, testes mecânicos de acordo com os padrões ASTM e EN, testes ultrassônicos para integridade interna e inspeção dimensional. Todos os produtos são fornecidos com certificados de teste de fábrica e documentação de rastreabilidade completa. Testes especiais, incluindo testes de fadiga, tenacidade à fratura e testes de corrosão, estão disponíveis mediante solicitação.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.38-0.45 |

| Silício (Si) | 0.17-0.37 |

| Manganês (Mn) | 0.50-0.80 |

| Fósforo (P) | ≤ 0.035 |

| Enxofre (S) | ≤ 0.035 |

| Cromo (Cr) | 0.90-1.20 |

| Molibdênio (Mo) | 0.15-0.25 |

| Níquel (Ni) | ≤ 0.30 |

| Cobre (Cu) | ≤ 0.25 |

| Alumínio (Al) | ≥ 0.020 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração (Rm) | 980-1180 MPa |

| Resistência de Escoamento (Rp0.2) | ≥ 785 MPa |

| Alongamento (A5) | ≥ 12% |

| Redução de Área (Z) | ≥ 45% |

| Dureza (HB) | 293-331 |

| Energia de Impacto (KV2) a 20°C | ≥ 63 J |

| Limite de Fadiga (10^7 ciclos) | 450-500 MPa |

| Módulo de Young | 210 GPa |

| Razão de Poisson | 0.27-0.30 |

| Módulo de Cisalhamento | 80 GPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1470-1520°C |

| Condutividade Térmica (20°C) | 42.6 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12.2×10-6/K |

| Capacidade Calorífica Específica | 460 J/kg·K |

| Resistividade Elétrica (20°C) | 0.27 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividade Térmica (20°C) | 11.8 mm²/s |

| Coeficiente de Expansão Linear (20-200°C) | 12.8×10-6/K |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

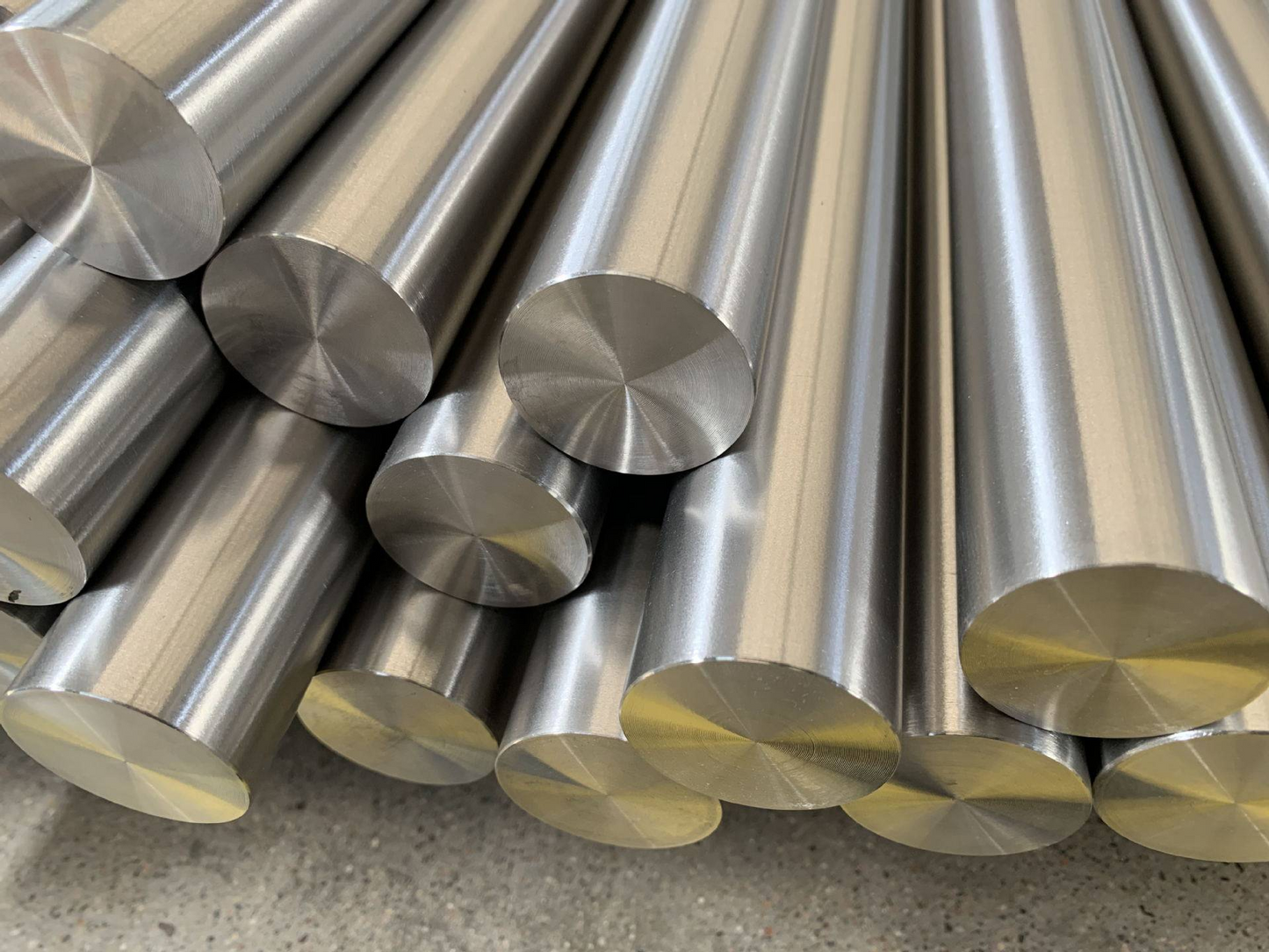

| Formas de Produto | Barras redondas, barras quadradas, barras planas, chapas, folhas, tubos, forjados |

| Diâmetro da Barra Redonda | 10-300 mm |

| Espessura da Chapa | 6-200 mm |

| Espessura da Folha | 0.5-6 mm |

| Comprimento | Até 12 metros (comprimentos personalizados disponíveis) |

| Normas | GB/T 3077, ASTM A29, EN 10083, JIS SCM440 |

| Acabamento de Superfície | Laminado a quente, trefilado a frio, descascado, retificado, usinado |

| Condição de Tratamento Térmico | Recozido, normalizado, temperado e revenido |

| Tolerância Dimensional | h9, h10, h11 (tolerâncias personalizadas disponíveis) |

| Retilineidade | ≤ 1mm/m |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing GB 42CrMo

Processamento Metalúrgico Avançado

MetalZenith emprega tecnologia de forno elétrico a arco de ponta com processos de refino secundário, incluindo tratamento em forno de panela e desgasificação a vácuo. Esta abordagem metalúrgica avançada garante homogeneidade química superior, conteúdo reduzido de inclusões e controle ideal da microestrutura para propriedades mecânicas aprimoradas.

Sistema Abrangente de Controle de Qualidade

Nosso sistema integrado de gestão da qualidade apresenta análise espectroscópica em tempo real, testes mecânicos automatizados, inspeção ultrassônica e verificação dimensional. Cada lote passa por rigorosos protocolos de teste com documentação de rastreabilidade completa, garantindo qualidade consistente e conformidade com padrões internacionais.

Personalização Flexível e Suprimento Global

MetalZenith oferece amplas capacidades de personalização, incluindo condições específicas de tratamento térmico, tolerâncias dimensionais e acabamentos de superfície. Nossa rede de distribuição global e gestão estratégica de inventário garantem um desempenho confiável da cadeia de suprimentos com prazos competitivos tanto para especificações padrão quanto personalizadas.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações