20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

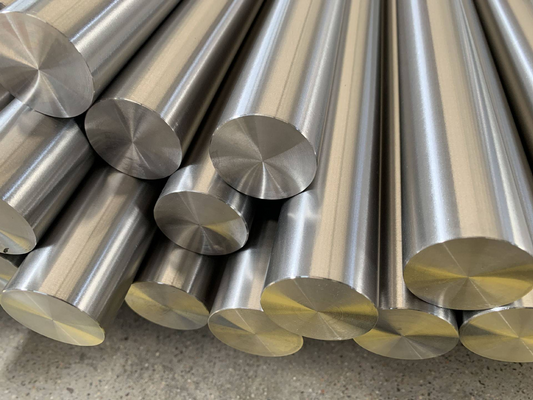

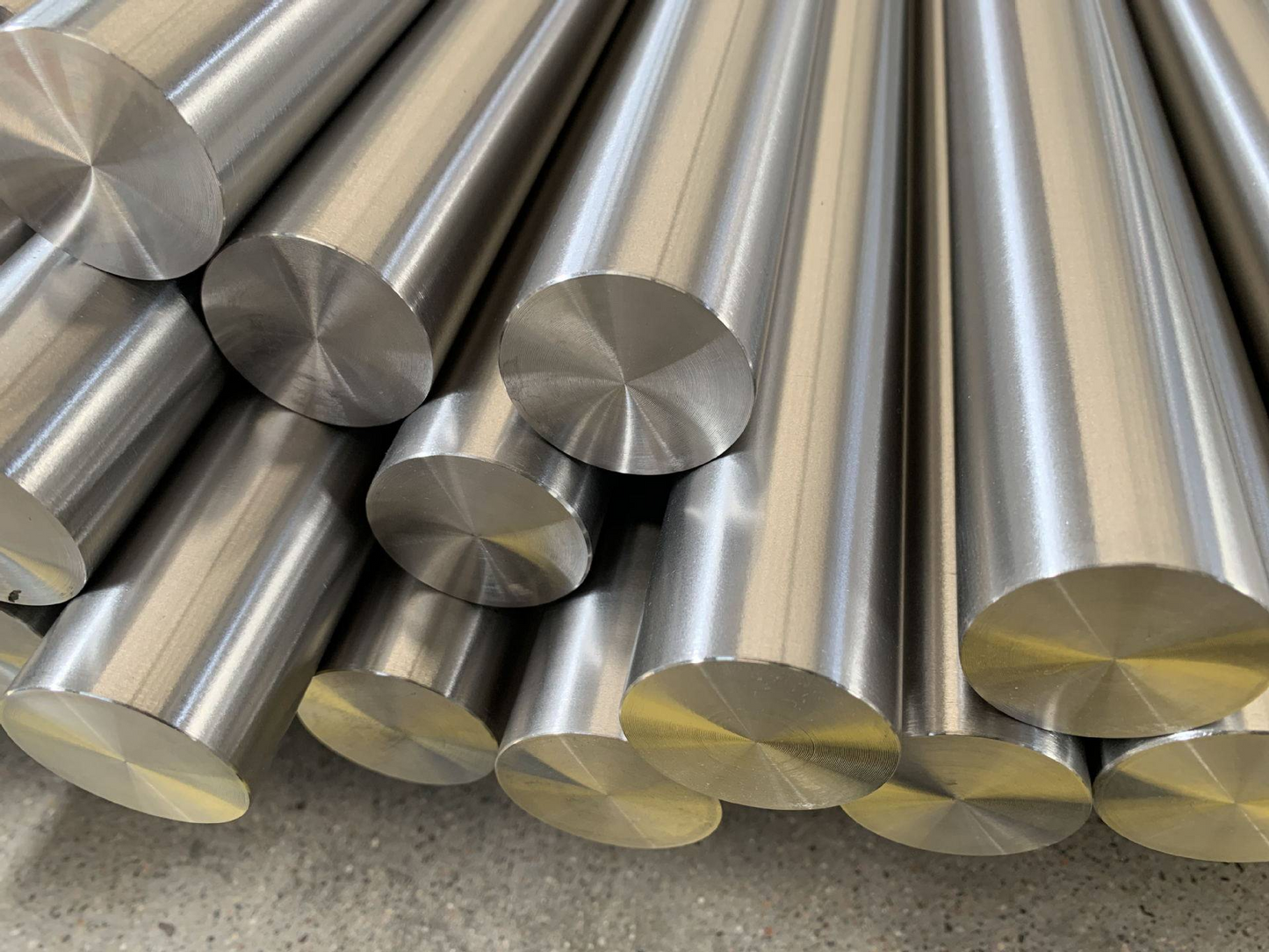

Product Overview

Características Metalúrgicas

O GB 16MnR é um aço de baixa liga com teor de manganês elevado, proporcionando maior resistência e tenacidade em comparação com aços carbono convencionais. O teor controlado de carbono garante excelente soldabilidade, mantendo a resistência adequada para aplicações em vasos de pressão. A microestrutura de grão fino alcançada através de laminação controlada e tratamento térmico de normalização contribui para propriedades mecânicas superiores e resistência ao impacto.

Processo de Tratamento Térmico

A MetalZenith emprega um tratamento térmico de normalização preciso a 900-950°C seguido de resfriamento ao ar para alcançar a microestrutura ideal. Este processo refina a estrutura do grão, melhora as propriedades mecânicas e alivia tensões internas. Um alívio de tensões adicional por recozimento a 600-650°C pode ser aplicado para seções grossas para garantir estabilidade dimensional e reduzir tensões residuais.

Processo de Fabricação

Nosso processo de fabricação começa com a fusão em forno de arco elétrico utilizando matérias-primas de alta qualidade, seguido de refino em panela para controle preciso da composição química. O aço passa por laminação controlada em nossos avançados moinhos de laminação a quente, garantindo propriedades mecânicas uniformes em toda a seção transversal. O processamento final inclui corte de precisão, tratamento de superfície e inspeção de qualidade abrangente.

Normas de Qualidade & Testes

Todos os produtos GB 16MnR fabricados pela MetalZenith estão em conformidade com as normas GB/T 713 e passam por testes rigorosos, incluindo análise química, teste de tração, teste de impacto, medição de dureza e inspeção ultrassônica. Certificação de terceiros e certificados de teste de moinho são fornecidos com cada remessa, garantindo total rastreabilidade e garantia de qualidade para aplicações críticas em vasos de pressão.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.12-0.20 |

| Manganês (Mn) | 1.20-1.60 |

| Silício (Si) | 0.20-0.55 |

| Fósforo (P) | ≤ 0.025 |

| Enxofre (S) | ≤ 0.015 |

| Cromo (Cr) | ≤ 0.25 |

| Níquel (Ni) | ≤ 0.30 |

| Cobre (Cu) | ≤ 0.25 |

| Alumínio (Al) | ≥ 0.020 |

| Nitrogênio (N) | ≤ 0.012 |

⚙️ Mechanical Properties

| Propriedade | Valor |

|---|---|

| Resistência à Tração (Rm) | 450-590 MPa |

| Resistência de Escoamento (ReL) | ≥ 295 MPa |

| Alongamento (A) | ≥ 21% |

| Energia de Impacto (KV2) a 20°C | ≥ 34 J |

| Energia de Impacto (KV2) a 0°C | ≥ 27 J |

| Dureza Brinell (HB) | 131-187 |

| Módulo de Young | 206 GPa |

| Razão de Poisson | 0.30 |

| Limite de Fadiga (10^7 ciclos) | 225 MPa |

🔬 Physical Properties

| Propriedade | Valor |

|---|---|

| Densidade | 7.85 g/cm³ |

| Ponto de Fusão | 1510°C |

| Condutividade Térmica (20°C) | 52 W/m·K |

| Coeficiente de Expansão Térmica (20-100°C) | 12.5×10-6/K |

| Capacidade Calorífica Específica | 460 J/kg·K |

| Resistividade Elétrica (20°C) | 0.18 µΩ·m |

| Permeabilidade Magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

📏 Product Specifications

| Especificação | Opções Disponíveis |

|---|---|

| Formas de Produto | Placas, Folhas, Barras, Forjados, Tubos |

| Espessura da Placa | 6-200 mm |

| Espessura da Folha | 0.5-6 mm |

| Diâmetro da Barra | 10-300 mm |

| Diâmetro Externo do Tubo | 21.3-1219 mm |

| Conformidade com Normas | GB/T 713, ASME SA-516, EN 10028-2 |

| Acabamento de Superfície | Laminado a Quente, Normalizado, Desengordurado |

| Tolerância Dimensional | ±0.1-0.5 mm (dependendo da forma) |

| Comprimento | Até 12 metros (comprimentos personalizados disponíveis) |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing GB 16MnR

Processamento Metalúrgico Avançado

MetalZenith emprega processos de tratamento térmico de laminação controlada e normalização de ponta, garantindo um refino de grão ideal e propriedades mecânicas superiores. Nossa tecnologia avançada de fornos garante controle preciso de temperatura e aquecimento uniforme para qualidade consistente em todo o material.

Controle de Qualidade Abrangente

Nosso laboratório de testes de última geração realiza análises químicas rigorosas, testes mecânicos, inspeção ultrassônica e verificação dimensional. Cada lote passa por documentação de rastreabilidade completa e certificação de terceiros para garantir conformidade com os padrões internacionais.

Soluções Personalizadas & Suprimento Global

MetalZenith oferece amplas capacidades de personalização, incluindo dimensões específicas, acabamentos de superfície e condições de tratamento térmico. Nossa rede de distribuição global garante entrega confiável em todo o mundo, com suporte técnico abrangente e serviços de consultoria em engenharia.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações