20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

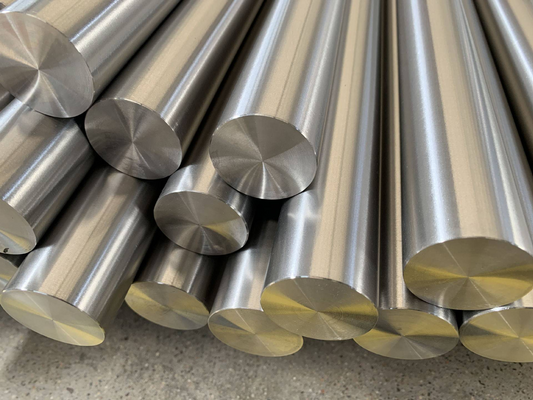

Product Overview

Características Metalúrgicas

AISI 1075 é um aço carbono de alto carbono, contendo 0,70-0,80% de carbono, o que proporciona excelente temperabilidade e resistência ao desgaste. O aço exibe uma microestrutura perlítica na condição recozida, transformando-se em martensita após o tratamento térmico adequado. O processo de fabricação controlado da MetalZenith garante distribuição uniforme de carbonetos e estrutura de grão ideal para propriedades mecânicas superiores.

Processo de Tratamento Térmico

A MetalZenith emprega ciclos de tratamento térmico controlados com precisão otimizados para AISI 1075. Austenitização é realizada a 790-820°C, seguida de resfriamento rápido em óleo ou água para alcançar a máxima dureza. O revenimento a 150-650°C permite o ajuste da dureza entre 42-50 HRC dependendo dos requisitos da aplicação. Nossos fornos controlados por computador garantem uniformidade de temperatura consistente e resultados reproduzíveis.

Processo de Fabricação

Nosso aço AISI 1075 é produzido utilizando tecnologia de forno a arco elétrico com processos de refino secundário, incluindo metalurgia de panela e desgasificação a vácuo. A fundição contínua garante composição química homogênea, enquanto a laminação e resfriamento controlados otimizam a microestrutura. O sistema de controle de qualidade da MetalZenith monitora cada etapa, desde a seleção da matéria-prima até a inspeção final.

Padrões de Qualidade & Certificações

Todos os produtos AISI 1075 fabricados pela MetalZenith estão em conformidade com ASTM A684, ASTM A29 e padrões internacionais equivalentes, incluindo EN 10132 e JIS G4801. Nosso sistema de gestão da qualidade certificado ISO 9001:2015 garante qualidade consistente do produto através de testes abrangentes, incluindo análise química, verificação de propriedades mecânicas, inspeção dimensional e exame metalográfico. Certificados de teste de moinho completos e documentação de rastreabilidade de material são fornecidos com cada remessa.

🧪 Chemical Composition

| Elemento | Composição (%) |

|---|---|

| Carbono (C) | 0.70 - 0.80 |

| Manganês (Mn) | 0.40 - 0.70 |

| Silício (Si) | 0.15 - 0.30 |

| Fósforo (P) | ≤ 0.030 |

| Enxofre (S) | ≤ 0.035 |

| Cromo (Cr) | ≤ 0.40 |

| Níquel (Ni) | ≤ 0.30 |

| Molibdênio (Mo) | ≤ 0.10 |

| Cobre (Cu) | ≤ 0.30 |

| Ferro (Fe) | Equilíbrio |

⚙️ Mechanical Properties

| Propriedade | Valor | Condição |

|---|---|---|

| Resistência à Tração | 1380 - 1520 MPa | Endurecido & Temperado |

| Resistência de Escoamento | 1240 - 1380 MPa | Endurecido & Temperado |

| Alongamento | 8 - 12% | Endurecido & Temperado |

| Redução de Área | 25 - 35% | Endurecido & Temperado |

| Dureza (HRC) | 42 - 50 | Endurecido & Temperado |

| Dureza (HB) | 180 - 220 | Recozido |

| Energia de Impacto (Charpy V) | 15 - 25 J | Temperatura Ambiente |

| Limite de Fadiga | 620 - 690 MPa | 107 ciclos |

| Módulo de Elasticidade | 210 GPa | Temperatura Ambiente |

🔬 Physical Properties

| Propriedade | Valor | Temperatura |

|---|---|---|

| Densidade | 7.85 g/cm³ | 20°C |

| Ponto de Fusão | 1460 - 1500°C | - |

| Condutividade Térmica | 46 W/m·K | 20°C |

| Coeficiente de Expansão Térmica | 12.1×10-6/K | 20-100°C |

| Capacidade Calorífica Específica | 486 J/kg·K | 20°C |

| Resistividade Elétrica | 0.18 µΩ·m | 20°C |

| Permeabilidade Magnética | Ferromagnético | 20°C |

| Temperatura de Curie | 770°C | - |

| Razão de Poisson | 0.27 - 0.30 | 20°C |

📏 Product Specifications

| Especificação | Opções Disponíveis | Normas |

|---|---|---|

| Formas de Produto | Barras Redondas, Barras Planas, Barras Quadradas, Faixas, Chapas, Fios | ASTM A684 |

| Diâmetro da Barra Redonda | 6mm - 300mm | ASTM A29 |

| Dimensões da Barra Plana | Espessura: 3-50mm, Largura: 20-300mm | ASTM A108 |

| Espessura da Chapa | 0.5mm - 12mm | ASTM A1011 |

| Diâmetro do Fio | 0.8mm - 12mm | ASTM A228 |

| Comprimento | Até 12 metros (comprimentos personalizados disponíveis) | Especificação do Cliente |

| Acabamento de Superfície | Laminação a Quente, Laminação a Frio, Descascado, Moído, Polido | ASTM A29 |

| Tolerância Dimensional | ±0.1mm a ±0.5mm (dependendo do tamanho) | ASTM A29 |

| Condição de Tratamento Térmico | Recozido, Normalizado, Endurecido & Temperado | Requisito do Cliente |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing AISI 1075

Tecnologia Avançada de Tratamento Térmico

MetalZenith emprega fornos de atmosfera controlada de última geração e sistemas de resfriamento de precisão para alcançar dureza e microestrutura ideais no aço AISI 1075. Nossos processos de tratamento térmico proprietários garantem propriedades mecânicas consistentes e características superiores de mola em toda a seção transversal do material.

Sistemas Abrangentes de Controle de Qualidade

Nossa instalação certificada pela ISO 9001:2015 possui equipamentos de teste avançados, incluindo espectrômetros, máquinas de teste universais e sistemas de análise metalográfica. Cada lote passa por uma rigorosa verificação da composição química, teste de propriedades mecânicas e exame microestrutural para garantir a conformidade com os padrões ASTM A684.

Processamento Personalizado e Cadeia de Suprimentos Global

MetalZenith oferece amplas capacidades de personalização, incluindo corte de precisão, tratamentos de superfície e ciclos de tratamento térmico especializados adaptados a aplicações específicas. Nossa rede de distribuição global garante entrega confiável em todo o mundo, apoiada por documentação técnica abrangente e serviços de suporte de engenharia.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações