20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

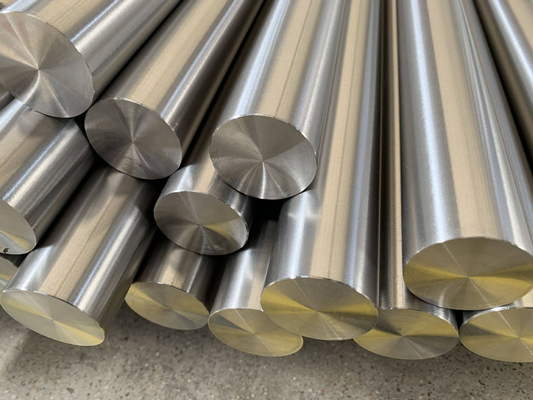

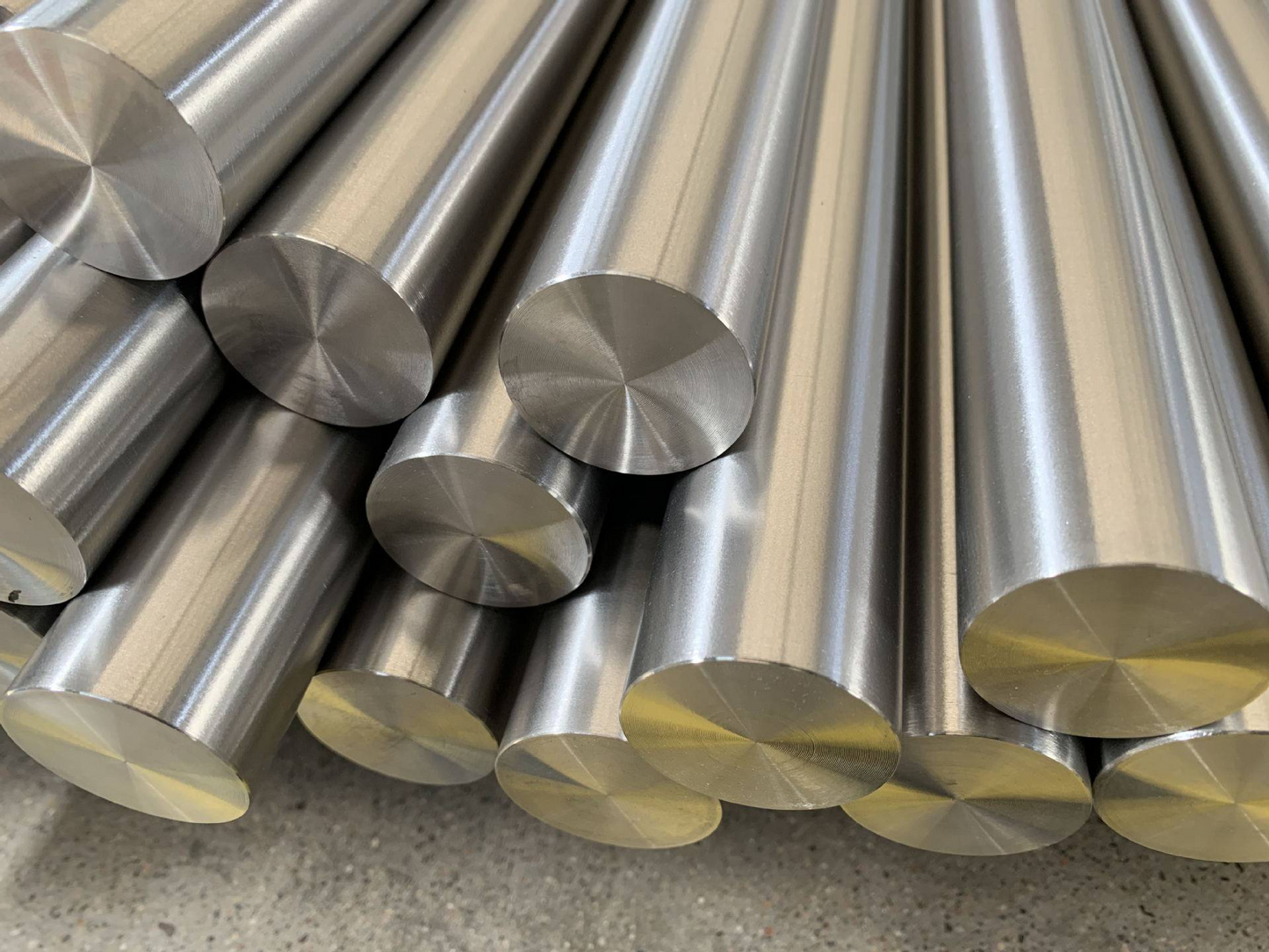

Product Overview

Metallurgical Characteristics

UNS N05500 is a precipitation-hardenable nickel-copper alloy with a face-centered cubic (FCC) austenitic matrix. The alloy achieves its high strength through the formation of coherent Ni&sub3;(Al,Ti) precipitates during age hardening. The microstructure consists of a nickel-copper solid solution matrix with uniformly distributed gamma-prime (γ') precipitates that provide strengthening through coherency strain and order hardening mechanisms.

Heat Treatment Process

MetalZenith employs a controlled three-stage heat treatment process: solution annealing at 980°C followed by rapid cooling, then age hardening at 595°C for 16 hours with furnace cooling. This precise thermal cycle ensures optimal precipitation kinetics and mechanical property development. Our computer-controlled furnaces maintain temperature uniformity within ±5°C throughout the treatment cycle.

Manufacturing Process Excellence

Production begins with vacuum induction melting (VIM) using high-purity raw materials, followed by electroslag remelting (ESR) for enhanced cleanliness. Hot working is performed between 1150-900°C with controlled reduction ratios to achieve optimal grain structure. Cold working capabilities include precision drawing, rolling, and machining operations with strict dimensional control.

Quality Standards and Testing

All UNS N05500 products undergo comprehensive testing including chemical analysis by optical emission spectroscopy, mechanical testing per ASTM E8/E8M, hardness verification, and microstructural examination. Non-destructive testing includes ultrasonic inspection, eddy current testing, and magnetic particle inspection where applicable. MetalZenith maintains full traceability from raw material to finished product with certified test reports meeting aerospace and marine industry requirements.

Corrosion Resistance and Environmental Performance

The alloy exhibits exceptional resistance to seawater, hydrofluoric acid, and various organic compounds. Its corrosion resistance stems from the protective oxide film formation and the inherent nobility of the nickel-copper matrix. Performance is maintained across temperatures from cryogenic conditions to 480°C, making it suitable for demanding marine and chemical processing environments.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 63.0 - 70.0 |

| Copper (Cu) | Remainder |

| Aluminum (Al) | 2.30 - 3.15 |

| Titanium (Ti) | 0.35 - 0.85 |

| Iron (Fe) | ≤ 2.00 |

| Manganese (Mn) | ≤ 1.50 |

| Carbon (C) | ≤ 0.25 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.010 |

⚙️ Mechanical Properties

| Property | Condition | Value |

|---|---|---|

| Tensile Strength | Age Hardened | ≥ 1035 MPa |

| Yield Strength (0.2% offset) | Age Hardened | ≥ 760 MPa |

| Elongation | Age Hardened | ≥ 20% |

| Hardness | Age Hardened | 28-35 HRC |

| Young's Modulus | Room Temperature | 179 GPa |

| Shear Modulus | Room Temperature | 66 GPa |

| Poisson's Ratio | Room Temperature | 0.32 |

| Impact Strength (Charpy V-notch) | Room Temperature | ≥ 35 J |

| Fatigue Strength (10&sup7; cycles) | Rotating Beam | 380 MPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 8.44 g/cm³ |

| Melting Point | 1350-1400°C |

| Thermal Conductivity (20°C) | 17.4 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 13.9×10-6/K |

| Specific Heat Capacity | 419 J/kg·K |

| Electrical Resistivity (20°C) | 0.52 µΩ·m |

| Magnetic Permeability | 1.002 (Non-magnetic) |

| Curie Temperature | -195°C |

| Thermal Diffusivity | 4.9×10-6 m²/s |

📏 Product Specifications

| Product Form | Size Range | Standards |

|---|---|---|

| Round Bar | 6-300 mm diameter | ASTM B865, AMS 4676 |

| Flat Bar | 10-100 mm thickness | ASTM B865 |

| Sheet | 0.5-6.0 mm thickness | ASTM B865, AMS 4676 |

| Plate | 6-100 mm thickness | ASTM B865 |

| Seamless Tube | 6-200 mm OD, 1-20 mm wall | ASTM B865, AMS 4676 |

| Wire | 0.1-10 mm diameter | ASTM B865 |

| Forging Stock | Custom dimensions | ASTM B865, AMS 4676 |

| Surface Finish | Hot rolled, Cold drawn, Machined, Polished | Ra 0.8-6.3 µm |

| Dimensional Tolerance | ±0.1-0.5 mm (depending on form) | ASTM standards |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing UNS N05500

Advanced Vacuum Melting Technology

MetalZenith utilizes state-of-the-art vacuum induction melting (VIM) and electroslag remelting (ESR) processes to produce UNS N05500 with superior chemical homogeneity, reduced inclusions, and exceptional purity levels that exceed industry standards for critical applications.

Precision Heat Treatment Capabilities

Our computer-controlled heat treatment facilities ensure optimal precipitation hardening with precise temperature control (±5°C) and atmosphere management, delivering consistent mechanical properties and microstructural integrity across all product forms and sizes.

Comprehensive Testing and Certification

MetalZenith provides complete material traceability with certified test reports including chemical analysis, mechanical testing, and microstructural examination. Our NADCAP-accredited laboratory ensures compliance with aerospace, marine, and industrial specifications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications