20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

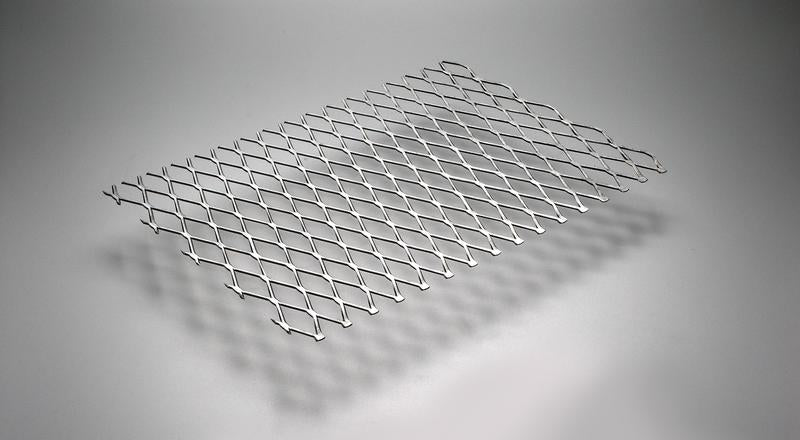

Product Overview

Steel Flattened Expanded Metal is manufactured from high-quality carbon steel through a precision expanding and flattening process. This versatile metal mesh product offers excellent strength-to-weight ratio and superior ventilation properties, making it ideal for industrial and architectural applications.

Key Features:

- High strength-to-weight ratio with excellent rigidity

- Superior ventilation and drainage capabilities

- Non-slip surface texture for safety applications

- Cost-effective alternative to perforated sheets

- Excellent paint and coating adhesion properties

Manufacturing Process: Produced through precision slitting and expanding of steel sheets followed by flattening process to create uniform thickness and smooth surface finish.

Applications: Industrial flooring, walkways, platforms, security fencing, filtration systems, ventilation grilles, architectural facades, and general screening applications.

🧪 Chemical Composition

| Element | Min % | Max % | Typical % | ASTM F1267 Requirement |

|---|---|---|---|---|

| Carbon (C) | - | 0.25 | 0.18 | ≤ 0.25 |

| Manganese (Mn) | 0.30 | 1.50 | 0.85 | 0.30-1.50 |

| Silicon (Si) | - | 0.40 | 0.25 | ≤ 0.40 |

| Phosphorus (P) | - | 0.040 | 0.025 | ≤ 0.040 |

| Sulfur (S) | - | 0.050 | 0.030 | ≤ 0.050 |

| Aluminum (Al) | - | 0.10 | 0.05 | ≤ 0.10 |

| Copper (Cu) | - | 0.35 | 0.20 | ≤ 0.35 |

| Nitrogen (N) | - | 0.012 | 0.008 | ≤ 0.012 |

| Iron (Fe) | Balance | Balance | 98.2 | Balance |

⚙️ Mechanical Properties

| Property | ASTM Requirement | Typical Value | Test Method | Temperature |

|---|---|---|---|---|

| Tensile Strength | 400 MPa min | 450 MPa | ASTM A370 | Room Temp |

| Yield Strength (0.2%) | 250 MPa min | 280 MPa | ASTM A370 | Room Temp |

| Elongation | 20% min | 25% | ASTM A370 | Room Temp |

| Hardness (Brinell) | - | 130 HB | ASTM E10 | Room Temp |

| Hardness (Rockwell B) | - | 75 HRB | ASTM E18 | Room Temp |

| Modulus of Elasticity | - | 200 GPa | ASTM E111 | Room Temp |

| Impact Energy (Charpy V) | - | 80+ J | ASTM E23 | Room Temp |

🔬 Physical Properties

| Property | Value | Unit | Temperature | Test Standard |

|---|---|---|---|---|

| Density | 7.85 | g/cm3 | 20°C | ASTM B311 |

| Melting Point | 1510-1540 | °C | - | DSC Analysis |

| Thermal Conductivity | 50.2 | W/m·K | 100°C | ASTM E1461 |

| Specific Heat | 460 | J/kg·K | 0-100°C | ASTM C351 |

| Linear Expansion | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| Electrical Resistivity | 170 | n|°¤m | 20°C | ASTM B193 |

| Magnetic Permeability | High | μ/μ₀ | Room Temp | ASTM A342 |

| Curie Temperature | 770 | °C | - | Ferromagnetic |

📏 Product Specifications

| Specification | Available Range | Standard Size | Custom Available | Tolerance |

|---|---|---|---|---|

| Sheet Thickness | 0.5mm - 8mm | 2mm | Yes | ±0.1mm |

| Sheet Width | 600mm - 2000mm | 1220mm | Yes | ±5mm |

| Sheet Length | 1000mm - 6000mm | 2440mm | Yes | ±10mm |

| Mesh Opening (LWD) | 3mm - 100mm | 20mm | Yes | ±1mm |

| Mesh Opening (SWD) | 2mm - 50mm | 10mm | Yes | ±0.5mm |

| Strand Width | 1mm - 10mm | 3mm | Yes | ±0.2mm |

| Open Area | 40% - 85% | 65% | Yes | ±3% |

| Surface Finish | Mill, Galvanized, PVC Coated | Mill | Yes | ASTM A123 |

| Standards Compliance | ASTM F1267, ISO 606 | ASTM F1267 | Multiple | Full compliance |

| Packaging | Pallets, Bundles, Crates | Pallets | Custom | Export standard |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing Steel Flattened Expanded Metal

Precision Cutting & Stretching

Advanced manufacturing process employs high-precision cutting and controlled stretching techniques to create uniform mesh patterns across steel sheets, ensuring consistent spacing and strand thickness throughout the entire material surface.

Controlled Flattening Process

Specialized rolling equipment applies precise pressure to flatten expanded metal surfaces, creating smooth, level planes that enhance material stability and improve surface contact area while maintaining structural integrity.

Optimized Material Efficiency

The expansion process maximizes raw material usage by creating openings without material waste, resulting in a lighter weight product that maintains structural strength while reducing overall material costs and environmental impact.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications