20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

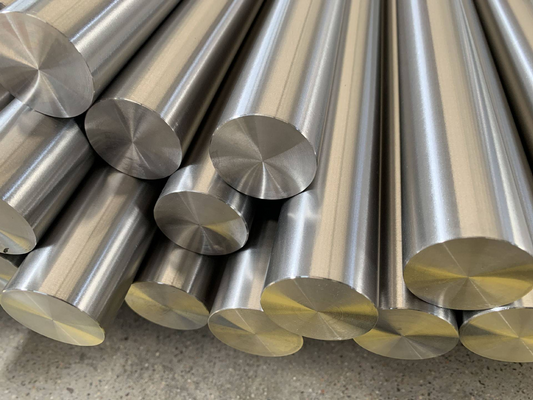

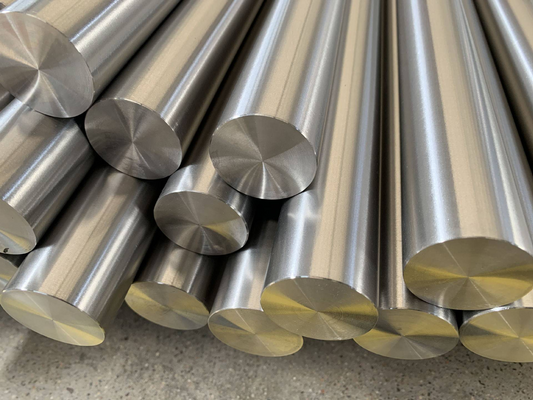

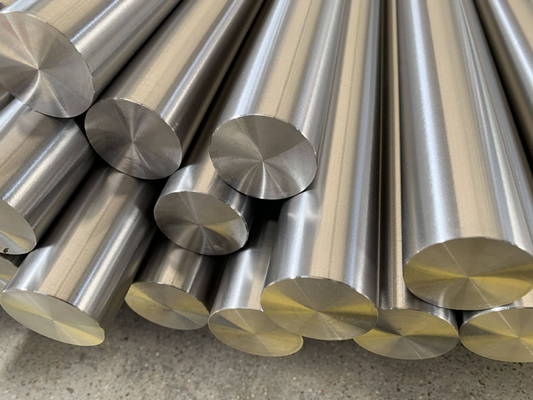

Product Overview

Metallurgical Characteristics

EN L290 is a low-carbon, microalloyed steel with a ferritic-pearlitic microstructure. The controlled addition of niobium, vanadium, and titanium provides grain refinement and precipitation strengthening, resulting in excellent strength-toughness balance. The fine-grained microstructure ensures superior low-temperature impact properties and resistance to brittle fracture.

Manufacturing Process

MetalZenith produces EN L290 through controlled rolling in the austenite recrystallization region followed by accelerated cooling. This thermomechanical controlled processing (TMCP) refines the grain structure and optimizes mechanical properties. Our continuous casting process ensures homogeneous chemical composition and minimal segregation. Advanced ladle metallurgy techniques including vacuum degassing and calcium treatment provide exceptional cleanliness levels.

Heat Treatment

EN L290 is typically supplied in the as-rolled condition with normalized microstructure. Optional heat treatments include stress relieving at 580-620°C for improved dimensional stability and normalized heat treatment at 900-950°C followed by air cooling for enhanced mechanical properties. Post-weld heat treatment may be applied at 580-620°C to relieve residual stresses.

Quality Standards

All EN L290 products manufactured by MetalZenith comply with EN 10208-2, API 5L PSL1 and PSL2, and ISO 3183 standards. Our quality management system includes 100% ultrasonic testing, hydrostatic pressure testing, dimensional inspection, and comprehensive mechanical testing. Chemical composition verification is performed using optical emission spectroscopy with certified reference materials. Impact testing is conducted according to EN 10045-1 using Charpy V-notch specimens at specified temperatures.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.28 |

| Manganese (Mn) | ≤ 1.40 |

| Silicon (Si) | ≤ 0.40 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.30 |

| Molybdenum (Mo) | ≤ 0.15 |

| Copper (Cu) | ≤ 0.50 |

| Niobium (Nb) | ≤ 0.05 |

| Vanadium (V) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.04 |

| Aluminum (Al) | ≥ 0.015 |

| Carbon Equivalent (CE) | ≤ 0.43 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (Rp0.2) | 290-440 MPa |

| Tensile Strength (Rm) | 415-565 MPa |

| Elongation (A) | ≥ 22% |

| Yield to Tensile Ratio | ≤ 0.93 |

| Hardness (HV10) | 150-250 |

| Impact Energy (KV2) at 0°C | ≥ 27 J |

| Impact Energy (KV2) at -20°C | ≥ 40 J |

| Impact Energy (KV2) at -40°C | ≥ 27 J |

| Fatigue Limit (10^7 cycles) | 180-220 MPa |

| Modulus of Elasticity | 210 GPa |

| Poisson's Ratio | 0.27-0.30 |

| Shear Modulus | 80 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.7 mm²/s |

| Coefficient of Linear Expansion (0-100°C) | 11.5×10-6/K |

| Emissivity (oxidized surface) | 0.79 |

📏 Product Specifications

| Specification | Details |

|---|---|

| Available Forms | Seamless Pipes, Welded Pipes, Plates, Sheets, Coils, Bars |

| Pipe Outer Diameter | 21.3-1422 mm |

| Wall Thickness | 2.0-80 mm |

| Plate Thickness | 6-100 mm |

| Plate Width | 1500-4000 mm |

| Length | 6-18 m (or as required) |

| Standards | EN 10208-2, API 5L, ISO 3183, ASTM A333 |

| Surface Finish | Black, Pickled, Oiled, Galvanized, Coated |

| End Preparation | Plain End, Beveled End, Threaded |

| Dimensional Tolerance | ±0.5% (thickness), ±1% (width/diameter) |

| Testing | Hydrostatic, NDT, Chemical Analysis, Mechanical Testing |

| Certification | Mill Test Certificate, Third Party Inspection Available |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN L290

Advanced TMCP Technology

MetalZenith employs thermomechanical controlled processing with precise temperature control and accelerated cooling to achieve fine-grained microstructure, ensuring superior mechanical properties and excellent low-temperature toughness in EN L290 steel.

Comprehensive Quality Control

Our integrated quality management system includes real-time chemical composition monitoring, automated mechanical testing, ultrasonic inspection, and dimensional verification, ensuring every EN L290 product meets or exceeds international standards.

Custom Processing Capabilities

MetalZenith offers extensive customization options including specialized heat treatments, precision machining, surface treatments, and cut-to-length services, delivering EN L290 products tailored to specific project requirements with global logistics support.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications