20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

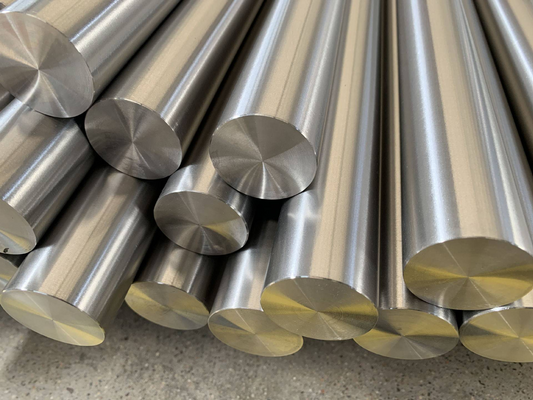

Product Overview

Metallurgical Characteristics

EN C75 is a eutectoid high-carbon steel with a microstructure primarily consisting of pearlite in the annealed condition. The 0.70-0.80% carbon content provides excellent hardenability and enables the formation of fine martensitic structures upon quenching. The balanced manganese content (0.40-0.70%) enhances hardenability while maintaining good ductility. Silicon content (0.15-0.35%) acts as a deoxidizer and contributes to spring properties by improving elastic limit.

Heat Treatment Processes

MetalZenith's heat treatment protocols for EN C75 include spheroidizing annealing at 680-720°C for optimal machinability, followed by controlled cooling. Hardening is performed at 780-820°C with water or oil quenching to achieve 58-62 HRC. Tempering temperatures range from 350-500°C depending on required hardness and spring properties. Our computer-controlled furnaces ensure uniform heating and precise temperature control throughout the cross-section.

Manufacturing Excellence

MetalZenith employs electric arc furnace melting followed by ladle refining and vacuum degassing to minimize inclusions and achieve precise chemistry. Continuous casting ensures homogeneous structure, while controlled hot rolling maintains optimal grain size. Cold drawing operations utilize diamond dies for superior surface finish and dimensional accuracy. Our integrated quality management system includes spectroscopic analysis, mechanical testing, and ultrasonic inspection.

Quality Standards & Certifications

All EN C75 products are manufactured under ISO 9001:2015 quality management systems with full traceability from raw materials to finished products. Testing includes chemical analysis per EN 10204 3.1, mechanical property verification, dimensional inspection, and surface quality assessment. MetalZenith maintains certifications for automotive (TS 16949), aerospace (AS9100), and railway (IRIS) applications, ensuring compliance with the most stringent industry requirements.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.70 - 0.80 |

| Manganese (Mn) | 0.40 - 0.70 |

| Silicon (Si) | 0.15 - 0.35 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Chromium (Cr) | ≤ 0.40 |

| Nickel (Ni) | ≤ 0.40 |

| Molybdenum (Mo) | ≤ 0.10 |

| Copper (Cu) | ≤ 0.40 |

| Aluminum (Al) | ≤ 0.050 |

⚙️ Mechanical Properties

| Property | Annealed Condition | Hardened & Tempered |

|---|---|---|

| Tensile Strength (Rm) | 750 - 950 MPa | 1200 - 1600 MPa |

| Yield Strength (Rp0.2) | 450 - 600 MPa | 900 - 1400 MPa |

| Elongation (A5) | ≥ 12% | 8 - 15% |

| Reduction of Area (Z) | ≥ 35% | 25 - 45% |

| Hardness (HB) | 220 - 280 | - |

| Hardness (HRC) | - | 38 - 50 |

| Impact Energy (KV) | ≥ 25 J | 15 - 35 J |

| Fatigue Limit (10^7 cycles) | 350 - 450 MPa | 500 - 700 MPa |

| Young's Modulus | 210 GPa | 210 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1460 - 1520°C |

| Thermal Expansion Coefficient (20-100°C) | 11.5×10-6/K |

| Thermal Expansion Coefficient (20-200°C) | 12.5×10-6/K |

| Thermal Conductivity (20°C) | 46 W/m·K |

| Specific Heat Capacity | 460 J/kg·K |

| Electrical Resistivity (20°C) | 0.18 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Poisson's Ratio | 0.27 - 0.30 |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round bars, flat bars, square bars, strips, sheets, plates, wire |

| Round Bar Diameter | 6 - 300 mm |

| Flat Bar Dimensions | 10-200 mm width × 3-80 mm thickness |

| Sheet/Plate Thickness | 0.5 - 100 mm |

| Wire Diameter | 0.5 - 20 mm |

| Standard Lengths | 3000, 6000, 9000, 12000 mm (custom lengths available) |

| Surface Finish | Hot rolled, cold drawn, peeled, ground, polished |

| Dimensional Tolerance | h9, h11 (cold drawn), +/-1% (hot rolled) |

| Standards Compliance | EN 10132-4, DIN 17222, ASTM A684, JIS G4801 |

| Heat Treatment Conditions | Annealed, normalized, hardened & tempered, spheroidized |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN C75

Advanced Vacuum Degassing Technology

MetalZenith employs state-of-the-art vacuum degassing and ladle refining systems to achieve ultra-low inclusion content and precise chemical composition control in EN C75 steel, ensuring superior fatigue life and consistent spring performance across all production batches.

Comprehensive Heat Treatment Capabilities

Our integrated heat treatment facilities feature computer-controlled furnaces with precise temperature and atmosphere control, enabling MetalZenith to deliver EN C75 steel in optimized conditions including spheroidized annealed, normalized, and custom-tempered states to meet specific application requirements.

Global Supply Chain & Custom Solutions

MetalZenith maintains strategic inventory locations worldwide and offers comprehensive customization services including precision cutting, surface treatments, and application-specific heat treatment schedules, supported by dedicated technical teams for engineering consultation and rapid delivery.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications