20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

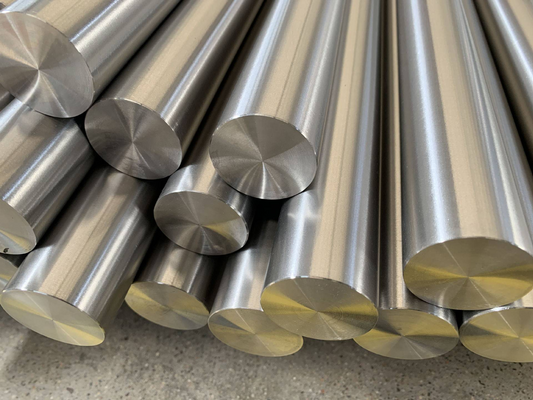

Product Overview

Metallurgical Structure & Composition

ASTM A36 is a low-carbon structural steel with a ferritic-pearlitic microstructure that provides excellent balance of strength, ductility, and weldability. The controlled carbon content (≤0.29%) ensures good formability while maintaining adequate strength for structural applications. MetalZenith's advanced steelmaking process includes ladle refining and vacuum degassing to minimize harmful inclusions and achieve superior cleanliness levels.

Manufacturing Process

Our ASTM A36 steel production utilizes electric arc furnace melting followed by ladle metallurgy for precise chemistry control. The steel undergoes continuous casting to produce high-quality billets and slabs, which are then hot rolled to final dimensions. MetalZenith's controlled rolling process optimizes grain structure and mechanical properties while maintaining dimensional accuracy within tight tolerances.

Heat Treatment & Processing

ASTM A36 steel is typically supplied in the hot-rolled condition without additional heat treatment. However, MetalZenith offers optional stress relieving at 550-650°C for applications requiring improved dimensional stability. Our normalizing treatment at 900-950°C can be applied to refine grain structure and enhance mechanical properties when specified by customers.

Quality Standards & Testing

Every batch of ASTM A36 steel undergoes comprehensive testing including chemical analysis by optical emission spectrometry, tensile testing per ASTM A370, and ultrasonic inspection for internal soundness. MetalZenith maintains full traceability from raw materials through final product delivery, with complete mill test certificates provided for each shipment. Our quality management system complies with ISO 9001:2015 and ASTM A36 specification requirements.

Welding & Fabrication Characteristics

ASTM A36 exhibits excellent weldability with all common welding processes including SMAW, GMAW, GTAW, and SAW. The low carbon equivalent (typically 0.40-0.45) minimizes risk of cold cracking and eliminates need for preheating in most applications. MetalZenith provides detailed welding procedure specifications and consumable recommendations to ensure optimal joint properties in fabricated structures.

🧪 Chemical Composition

| Element | Composition (%) | Specification |

|---|---|---|

| Carbon (C) | 0.25-0.29 | ≤ 0.29% max |

| Manganese (Mn) | 0.80-1.20 | 0.80-1.20% |

| Silicon (Si) | 0.15-0.40 | 0.15-0.40% |

| Phosphorus (P) | ≤ 0.040 | 0.040% max |

| Sulfur (S) | ≤ 0.050 | 0.050% max |

| Chromium (Cr) | ≤ 0.20 | Residual |

| Nickel (Ni) | ≤ 0.20 | Residual |

| Molybdenum (Mo) | ≤ 0.15 | Residual |

| Copper (Cu) | ≤ 0.20 | When specified |

| Iron (Fe) | Balance | Remainder |

⚙️ Mechanical Properties

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | 400-550 MPa (58-80 ksi) | ASTM A370 |

| Yield Strength (0.2% offset) | ≥ 250 MPa (36 ksi) | ASTM A370 |

| Elongation in 50mm | ≥ 20% | ASTM A370 |

| Elongation in 200mm | ≥ 23% | ASTM A370 |

| Brinell Hardness | 119-162 HB | ASTM E10 |

| Rockwell Hardness | 67-87 HRB | ASTM E18 |

| Charpy V-Notch Impact (20°C) | ≥ 27 J (20 ft-lbs) | ASTM A370 |

| Young's Modulus | 200-210 GPa | ASTM E111 |

| Shear Modulus | 80 GPa | ASTM E143 |

| Poisson's Ratio | 0.26-0.30 | ASTM E132 |

🔬 Physical Properties

| Property | Value | Temperature |

|---|---|---|

| Density | 7.85 g/cm³ | 20°C |

| Melting Point | 1425-1540°C | - |

| Thermal Conductivity | 51.9 W/m·K | 20°C |

| Thermal Expansion Coefficient | 11.7×10-6/K | 20-100°C |

| Specific Heat Capacity | 486 J/kg·K | 20°C |

| Electrical Resistivity | 0.162 µΩ·m | 20°C |

| Magnetic Permeability | Ferromagnetic | 20°C |

| Curie Temperature | 770°C | - |

| Thermal Diffusivity | 13.6 mm²/s | 20°C |

| Emissivity | 0.87-0.95 | Oxidized surface |

📏 Product Specifications

| Specification | Available Options | Standards |

|---|---|---|

| Product Forms | Plates, Sheets, Bars, Beams, Channels, Angles, Tubes | ASTM A36 |

| Plate Thickness | 6mm - 200mm (0.25' - 8') | ASTM A36 |

| Sheet Thickness | 0.5mm - 6mm (0.02' - 0.25') | ASTM A36 |

| Bar Diameter | 10mm - 300mm (0.4' - 12') | ASTM A36 |

| Width Range | 100mm - 3000mm (4' - 120') | ASTM A36 |

| Length Range | 1000mm - 12000mm (40' - 480') | ASTM A36 |

| Surface Finish | Hot Rolled, Cold Rolled, Pickled, Shot Blasted | ASTM A36 |

| Edge Condition | Mill Edge, Sheared Edge, Flame Cut, Machined | ASTM A36 |

| Dimensional Tolerance | ±0.5mm to ±3mm depending on size | ASTM A6 |

| Equivalent Standards | EN S235JR, JIS SS400, GB Q235B | International |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing ASTM A36

Advanced Electric Arc Furnace Technology

MetalZenith utilizes state-of-the-art electric arc furnace technology with precise temperature control and automated charging systems, ensuring optimal chemical composition and metallurgical cleanliness in every heat of ASTM A36 steel production.

Comprehensive Quality Control Laboratory

Our ISO 17025 accredited testing laboratory features advanced spectrometers, universal testing machines, and metallographic equipment, providing complete chemical analysis, mechanical testing, and microstructural evaluation for guaranteed ASTM A36 compliance.

Flexible Production & Custom Processing

MetalZenith offers extensive customization capabilities including precision cutting, surface treatment, heat treatment, and special packaging. Our flexible production scheduling and global logistics network ensure timely delivery of ASTM A36 steel in any required form or specification.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications