20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

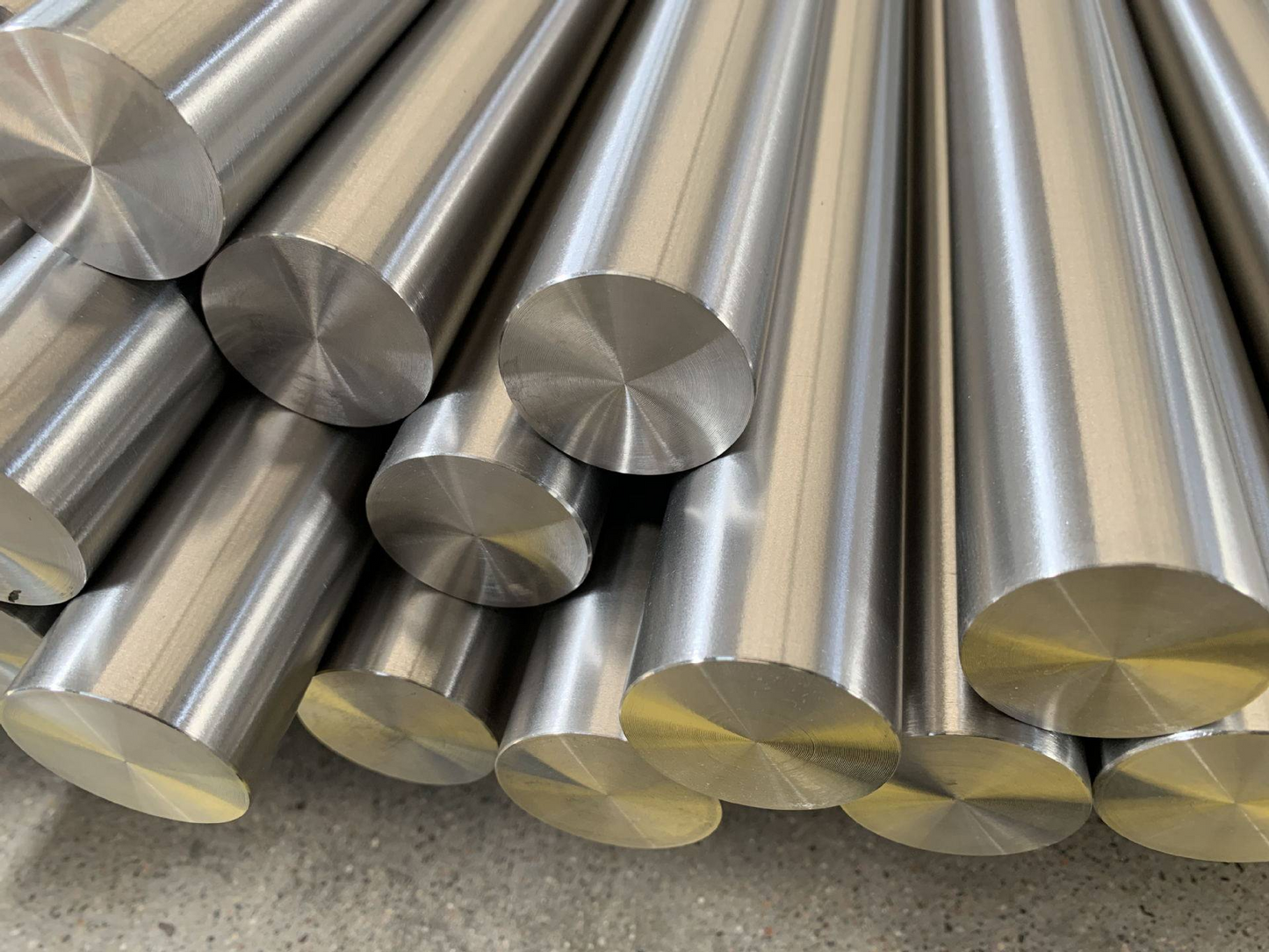

Product Overview

Metallurgical Characteristics

AISI 4150 is a medium-carbon, low-alloy steel with chromium and molybdenum as primary alloying elements. The chromium content (0.80-1.10%) enhances hardenability and provides moderate corrosion resistance, while molybdenum (0.15-0.25%) improves high-temperature strength, creep resistance, and prevents temper brittleness. The balanced carbon content (0.48-0.53%) ensures optimal strength-ductility combination after heat treatment.

Heat Treatment Process

MetalZenith's precision heat treatment involves austenitizing at 845-870°C, followed by oil quenching to achieve martensitic structure. Tempering is performed at 540-650°C depending on desired hardness levels. Our computer-controlled furnaces ensure uniform heating rates and precise temperature control, resulting in consistent mechanical properties and minimal distortion.

Manufacturing Process Excellence

Our AISI 4150 production begins with electric arc furnace melting using premium scrap and alloy additions. Secondary refining through ladle metallurgy and vacuum degassing ensures chemical homogeneity and cleanliness. Continuous casting produces high-quality billets, which undergo controlled rolling to achieve desired mechanical properties and grain structure refinement.

Quality Standards & Testing

Every batch undergoes comprehensive quality control including spectrographic analysis, tensile testing, hardness verification, impact testing, and ultrasonic inspection. MetalZenith maintains compliance with ASTM A29, ASTM A322, and international standards. Our ISO 17025 accredited laboratory ensures accurate testing and certification. Traceability is maintained from raw materials through final delivery, providing complete documentation for critical applications.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.48 - 0.53 |

| Manganese (Mn) | 0.75 - 1.00 |

| Silicon (Si) | 0.15 - 0.35 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Chromium (Cr) | 0.80 - 1.10 |

| Molybdenum (Mo) | 0.15 - 0.25 |

| Nickel (Ni) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.35 |

| Aluminum (Al) | 0.020 - 0.050 |

⚙️ Mechanical Properties

| Property | Annealed Condition | Quenched & Tempered |

|---|---|---|

| Tensile Strength | 630 - 780 MPa | 1030 - 1380 MPa |

| Yield Strength (0.2% offset) | 415 MPa | 895 - 1205 MPa |

| Elongation in 50mm | ≥ 22% | 12 - 18% |

| Reduction of Area | ≥ 50% | 40 - 55% |

| Brinell Hardness (HB) | 187 - 229 | 302 - 388 |

| Rockwell Hardness (HRC) | - | 32 - 42 |

| Impact Energy (Charpy V-notch) | 54 J | 27 - 81 J |

| Fatigue Limit (10^7 cycles) | 280 MPa | 450 - 620 MPa |

| Modulus of Elasticity | 205 GPa | 205 GPa |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1480 - 1520°C |

| Thermal Conductivity (20°C) | 42.7 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 11.2×10-6/K |

| Thermal Expansion Coefficient (20-200°C) | 11.9×10-6/K |

| Thermal Expansion Coefficient (20-400°C) | 12.8×10-6/K |

| Specific Heat Capacity | 486 J/kg·K |

| Electrical Resistivity (20°C) | 0.27 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Poisson's Ratio | 0.27 - 0.30 |

| Shear Modulus | 80 GPa |

📏 Product Specifications

| Specification | Available Options |

|---|---|

| Product Forms | Round bars, Square bars, Flat bars, Plates, Sheets, Forgings, Tubes |

| Round Bar Diameter | 10mm - 500mm |

| Square Bar Size | 10mm - 300mm |

| Flat Bar Dimensions | Thickness: 5-100mm, Width: 20-500mm |

| Plate Thickness | 8mm - 200mm |

| Standard Lengths | 3m, 6m, 9m, 12m (Custom lengths available) |

| Standards Compliance | ASTM A29, ASTM A322, SAE J404, EN 10083-3, JIS G4105 |

| Surface Finish | Hot rolled, Cold drawn, Peeled, Ground, Machined |

| Dimensional Tolerance | h9, h10, h11 (ISO 286-2) |

| Heat Treatment Condition | Annealed, Normalized, Quenched & Tempered |

| Testing & Certification | Mill Test Certificate, Third-party inspection, Ultrasonic testing |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing AISI 4150

Advanced Vacuum Degassing Technology

MetalZenith employs cutting-edge vacuum degassing and ladle refining processes to achieve ultra-low sulfur and phosphorus content in AISI 4150, resulting in superior cleanliness, enhanced fatigue life, and improved machinability compared to conventional production methods.

Precision Heat Treatment Control

Our computer-controlled heat treatment facilities with multi-zone temperature monitoring ensure precise austenitizing, quenching, and tempering cycles. This advanced process control guarantees consistent mechanical properties and optimal microstructure throughout the entire cross-section of AISI 4150 components.

Comprehensive Customization Capabilities

MetalZenith offers extensive customization options including specialized heat treatments, precision machining, surface treatments, and non-standard dimensions. Our engineering team provides technical support for application-specific requirements, ensuring optimal performance in demanding service conditions.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications