20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

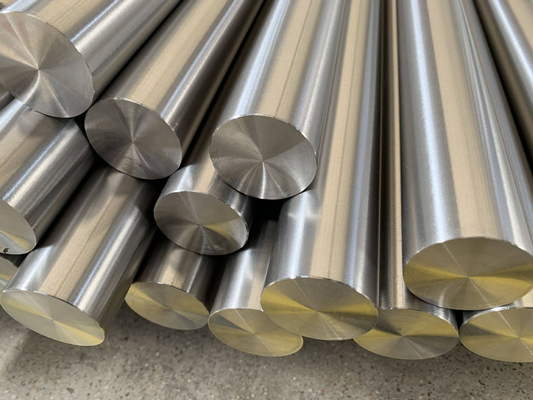

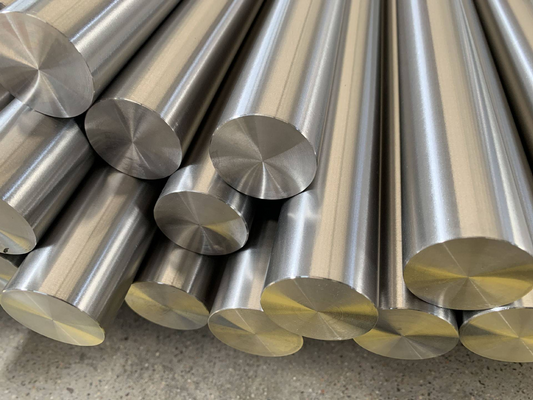

Product Overview

冶金特性

UNS N10665は、還元環境において優れた耐腐食性を持つ固溶体強化ニッケル-モリブデン合金です。高いモリブデン含有量(26-30%)は、塩酸、硫酸、その他の還元媒体に対する優れた耐性を提供します。この合金は、650°Cまでの温度で耐腐食性を維持し、優れた熱安定性を示します。

熱処理と加工

MetalZenithは、1065-1120°Cでの固溶化アニーリングを行い、その後急冷して最適な特性を得ます。この合金は析出硬化によって硬化することはできませんが、冷間加工によって強度を得ます。私たちの制御された雰囲気の熱処理は、酸化を防ぎ、表面品質を維持します。熱間加工は、割れを防ぐために温度を慎重に制御しながら1010-1175°Cの間で行われます。

製造プロセスの優秀性

私たちの製造プロセスは、高純度の原材料を使用した真空誘導溶解から始まり、その後、清浄度を向上させるために真空アーク再溶解を行います。インゴットは、熱間加工の前に均質化熱処理を受けます。MetalZenithの高度な圧延および鍛造能力は、製品の断面全体にわたって均一な微細構造と機械的特性を確保します。

品質基準と試験

すべてのUNS N10665製品は、光学放出分光法による化学分析、ASTM基準に基づく機械試験、超音波検査、専門的な腐食試験を含む包括的な試験を受けます。MetalZenithは、原材料から完成品までの完全なトレーサビリティを維持し、製鋼試験証明書、熱処理記録、寸法検査報告書を含む詳細な文書を提供します。私たちの品質システムは、ASTM B333、NACE MR0175、およびその他の関連国際基準に準拠しています。

🧪 Chemical Composition

| 要素 | 組成 (%) |

|---|---|

| ニッケル (Ni) | バランス (62.0 最小) |

| モリブデン (Mo) | 26.0 - 30.0 |

| クロム (Cr) | ≤ 1.0 |

| 鉄 (Fe) | ≤ 2.0 |

| コバルト (Co) | ≤ 1.0 |

| 炭素 (C) | ≤ 0.02 |

| マンガン (Mn) | ≤ 1.0 |

| シリコン (Si) | ≤ 0.10 |

| リン (P) | ≤ 0.04 |

| 硫黄 (S) | ≤ 0.03 |

⚙️ Mechanical Properties

| 特性 | 値 |

|---|---|

| 引張強度(究極) | 760 - 1035 MPa |

| 降伏強度(0.2% オフセット) | ≥ 350 MPa |

| 50mmでの伸び | ≥ 40% |

| 硬度(ブリネル) | ≤ 230 HB |

| 硬度(ロックウェルB) | ≤ 100 HRB |

| ヤング率 | 230 GPa |

| せん断弾性率 | 85 GPa |

| ポアソン比 | 0.35 |

| 衝撃エネルギー(シャルピーVノッチ) | ≥ 200 J |

🔬 Physical Properties

| プロパティ | 値 |

|---|---|

| 密度 | 9.24 g/cm³ |

| 融点 | 1370 - 1400°C |

| 熱伝導率 (100°C) | 11.1 W/m·K |

| 熱伝導率 (500°C) | 18.4 W/m·K |

| 熱膨張 (20-100°C) | 11.1×10-6/K |

| 熱膨張 (20-500°C) | 12.4×10-6/K |

| 比熱 (20°C) | 377 J/kg·K |

| 電気抵抗率 (20°C) | 1.31 µΩ·m |

| 磁気透過率 | 1.002 (常磁性) |

| キュリー温度 | 非磁性 |

📏 Product Specifications

| 仕様 | 利用可能なオプション |

|---|---|

| 製品形状 | 丸棒、平棒、シート、プレート、チューブ、パイプ、鍛造品、ワイヤー |

| 丸棒直径 | 6mm - 300mm |

| 平棒寸法 | 10×3mm - 200×50mm |

| シート厚さ | 0.5mm - 6mm |

| プレート厚さ | 6mm - 100mm |

| チューブ外径 | 6mm - 219mm |

| 規格 | ASTM B333, ASTM B564, ASTM B619, ASTM B622, ASTM B626, ASTM B574 |

| 表面仕上げ | 熱間圧延、冷間圧延、焼鈍、酸洗い、研磨 |

| 寸法公差 | ±0.1mmから±0.5mm(形状とサイズに依存) |

| 長さ | 最大12メートル(カスタム長さあり) |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing UNS N10665

高度な真空溶融技術

MetalZenithは、最先端の真空誘導溶解(VIM)および真空アーク再溶解(VAR)プロセスを利用して、優れた化学均一性、最小限の不純物、並びに卓越した冶金品質を持つUNS N10665を生産しています。私たちの制御された雰囲気処理は、最適な純度と性能特性を保証します。

包括的な品質管理システム

私たちの統合品質管理システムには、高度な分光分析、機械試験ラボ、および専門的な腐食試験施設が含まれています。すべてのバッチは厳格な検査を受け、完全なトレーサビリティ文書が提供され、一貫した材料特性と国際基準への適合が保証されます。

カスタム処理とグローバル供給

MetalZenithは、精密加工、熱処理の最適化、特別な表面処理を含む広範なカスタマイズ機能を提供します。私たちのグローバルな流通ネットワークと戦略的な在庫管理は、柔軟な配送オプションを備えた信頼性の高いサプライチェーンのパフォーマンスを確保します。

あなたの信頼できる 鋼

製造パートナー

クイックお問い合わせ

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証