20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

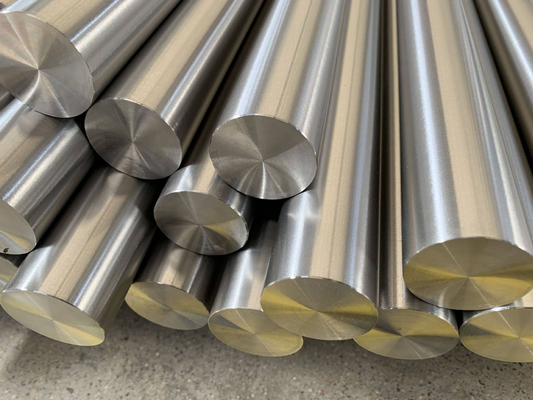

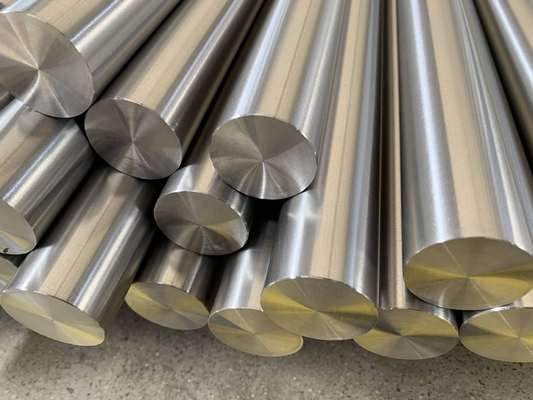

Product Overview

Karakteristik Metalurgi

Baja laut AH32 memiliki struktur mikro ferritik-perlit halus yang dicapai melalui penggulungan terkontrol dan perlakuan panas normalisasi. Komposisi baja dioptimalkan dengan elemen mikroaloying termasuk niobium, vanadium, dan titanium untuk memberikan penyempurnaan butir dan penguatan presipitasi. Ini menghasilkan rasio kekuatan-terhadap-berat yang sangat baik dan ketangguhan suhu rendah yang superior yang penting untuk aplikasi laut.

Proses Perlakuan Panas

MetalZenith menerapkan proses normalisasi yang tepat di mana baja AH32 dipanaskan hingga 900-950°C dan didinginkan dengan udara untuk mencapai sifat mekanik yang optimal. Sistem pendinginan terkontrol kami memastikan distribusi suhu yang merata dan struktur butir yang konsisten di seluruh ketebalan material. Perlakuan penghilang stres tambahan pada 580-620°C dapat diterapkan untuk aplikasi tertentu yang memerlukan stabilitas dimensi yang lebih baik.

Keunggulan Manufaktur

Fasilitas produksi kami yang canggih memanfaatkan teknologi pengolahan terkontrol termomekanis (TMCP) yang maju. Proses manufaktur mencakup pengecoran kontinu, penggulungan terkontrol dengan pemantauan suhu yang tepat, dan sistem pendinginan yang dipercepat. Pemantauan kualitas secara real-time memastikan komposisi kimia dan sifat mekanik yang konsisten. Setiap batch produksi menjalani pengujian komprehensif termasuk pengujian tarik, pengujian impak, dan pemeriksaan ultrasonik.

Standar Kualitas & Kepatuhan

Baja laut AH32 MetalZenith sepenuhnya mematuhi standar internasional termasuk EN 10225, ASTM A131 Grade AH32, dan JIS G3136. Sistem manajemen kualitas kami bersertifikat ISO 9001:2015 dan ISO 14001:2015. Semua produk diproduksi di bawah kontrol kualitas yang ketat dengan pelacakan penuh dari bahan baku hingga produk jadi. Layanan inspeksi dan pengujian pihak ketiga tersedia melalui laboratorium terakreditasi untuk memastikan kepuasan pelanggan yang lengkap dan kepatuhan regulasi.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | ≤ 0.18 |

| Mangan (Mn) | 0.90 - 1.60 |

| Silikon (Si) | 0.10 - 0.50 |

| Fosfor (P) | ≤ 0.035 |

| Belerang (S) | ≤ 0.035 |

| Aluminium (Al) | ≥ 0.015 |

| Niobium (Nb) | 0.02 - 0.05 |

| Vanadium (V) | 0.05 - 0.10 |

| Titanium (Ti) | 0.02 - 0.05 |

| Tembaga (Cu) | ≤ 0.35 |

| Kromium (Cr) | ≤ 0.20 |

| Nikel (Ni) | ≤ 0.40 |

| Molybdenum (Mo) | ≤ 0.08 |

⚙️ Mechanical Properties

| Properti | Nilai |

|---|---|

| Kekuatan Tarik (ReH) | ≥ 315 MPa |

| Kekuatan Tarik (Rm) | 440 - 570 MPa |

| Panjang Regangan (A5) | ≥ 22% |

| Energi Impak (KV pada 0°C) | ≥ 34 J |

| Energi Impak (KV pada -20°C) | ≥ 24 J |

| Kekerasan Brinell (HB) | 150 - 190 |

| Modulus Young | 210 GPa |

| Rasio Poisson | 0.30 |

| Batas Kelelahan (10&sup7; siklus) | 220 MPa |

| Ketangguhan Patah (KIC) | 150 MPa·m¹⁄² |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan | 7.85 g/cm³ |

| Titik Leleh | 1510°C |

| Konduktivitas Termal (20°C) | 54 W/m·K |

| Ekspansi Termal (20-100°C) | 12×10-6/K |

| Kapasitas Panas Spesifik | 500 J/kg·K |

| Resistivitas Listrik | 0.16 µΩ·m |

| Permeabilitas Magnetik | Ferromagnetik |

| Difusivitas Termal | 13.8 mm²/s |

| Suhu Curie | 770°C |

📏 Product Specifications

| Spesifikasi | Detail |

|---|---|

| Bentuk yang Tersedia | Pelat, Lembaran, Gulungan, Potongan sesuai ukuran |

| Rentang Ketebalan | 6 - 150 mm |

| Rentang Lebar | 1500 - 4000 mm |

| Rentang Panjang | 6000 - 18000 mm |

| Standar | EN 10225, ASTM A131, JIS G3136, GB/T 712 |

| Finishing Permukaan | Ditempa Panas, Ditembak Pasir, Diasamkan |

| Kondisi Ujung | Ujung Pabrik, Ujung Dipangkas, Ujung Dipotong |

| Toleransi Ketebalan | ±0.3 mm (6-40mm), ±0.5 mm (>40mm) |

| Toleransi Lebar | ±5 mm |

| Toleransi Panjang | ±10 mm |

| Datar | ≤5 mm/m |

| Masyarakat Klasifikasi | ABS, DNV-GL, LR, BV, CCS, NK, RINA |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing AH32

Pemrosesan Termomekanik Lanjutan

MetalZenith menggunakan teknologi penggulungan terkendali dan normalisasi mutakhir dengan sistem kontrol suhu yang tepat, memastikan struktur butir yang optimal dan sifat mekanik yang superior di setiap pelat baja AH32 yang kami produksi.

Sertifikasi Kualitas Komprehensif

Baja laut AH32 kami telah disertifikasi oleh semua lembaga klasifikasi utama termasuk ABS, DNV-GL, dan Lloyd's Register, dengan pelacakan lengkap dan pengujian pihak ketiga untuk menjamin kepatuhan terhadap standar laut internasional.

Solusi Laut Kustom

MetalZenith menawarkan kemampuan kustomisasi yang luas untuk baja AH32 termasuk pemotongan dimensi yang tepat, perlakuan permukaan, dan perlakuan panas khusus untuk memenuhi persyaratan spesifik dalam pembangunan kapal dan aplikasi lepas pantai.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi