What are the Properties and Applications of Hot Rolled Steel Bars

Share

Table Of Content

Table Of Content

Hot rolled steel bars are important in many industries today. They are strong and can be used in many ways. These bars are used in building, cars, and energy projects. They are long-lasting and save money, so they are very useful. In 2023, the global market for these bars was worth about $100 billion. By 2032, it might grow to $165 billion. This shows how needed they are for making beams, car frames, and energy systems. Their special way of being made helps them work well for many jobs. This makes them a trusted choice for different projects.

Key Takeaways

- Hot rolled steel bars are strong and long-lasting, perfect for building and machines.

- These bars are simple to shape and bend for custom uses.

- They are cheaper to make than cold rolled steel, saving money.

- Their rough surface helps paint or coatings stick well, great for concrete.

- Hot rolled steel bars are used in building, cars, farming, and energy work.

- Picking the right type of steel is key for strength and flexibility.

- More industries need hot rolled steel bars, so demand is rising.

- Using recycled steel is common now, making production more eco-friendly.

What Are Hot Rolled Steel Bars?

Definition and Characteristics

Hot rolled steel bars are useful materials used in many industries. These include car making, farming, mining, and building. They come in shapes like strips, squares, rounds, and flats. This makes them fit for many jobs. Grades like A569, AISI 1008, A36, A529-50, and A572-50 show their strength and uses. Rules like ASTM A36 and EN 10025 set safety and performance standards. Labels and certifications prove they meet these rules, like the Commercial Standard CS 150-48 for rail steel bars.

Overview of the Hot Rolling Process

Heating Above Recrystallization Temperature

The hot rolling process starts by heating steel very high, around 1,100°F (593°C). This heat softens the steel, making it easy to shape. The temperature must be controlled carefully. Small changes can ruin the product and cost money.

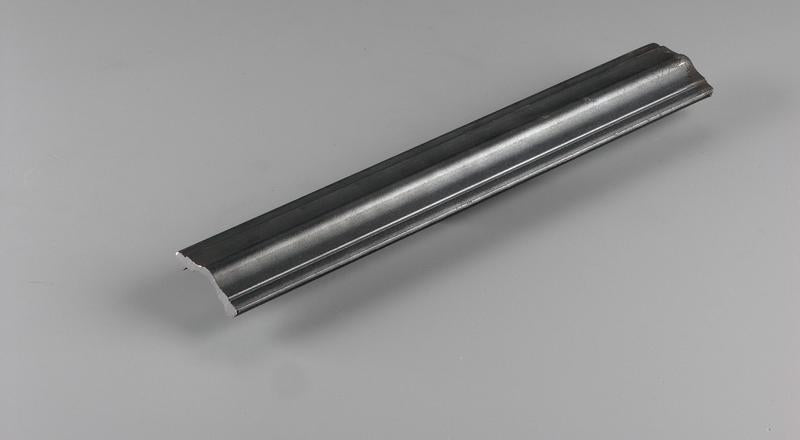

Shaping and Cooling

After heating, the steel goes through rollers to get its shape. It can become bars or sheets. The pressure must be just right to avoid machine damage and ensure good results. After shaping, the steel cools naturally. This gives it a rough surface, which can later be polished or coated to look better and resist rust.

Key Differences Between Hot Rolled and Cold Rolled Steel Bars

Hot rolled steel bars are not the same as cold rolled ones:

- Manufacturing Process: Hot rolling heats steel above 1,100°F, while cold rolling shapes it cold.

- Surface Finish: Hot rolled bars feel rough, but cold rolled bars are smooth.

- Cost: Hot rolled bars are cheaper to make, saving money for big projects.

- Strength and Precision: Cold rolled bars are stronger and more exact. Hot rolled bars bend easier and are simpler to work with.

These differences make hot rolled bars great for building strong, affordable structures where looks and exact sizes matter less.

Properties of Hot Rolled Steel Bars

Strong and Durable

Hot rolled steel bars are very strong and durable. They can hold heavy weights without breaking. This makes them great for bridges, buildings, and machines. Their strength comes from how they are made. The hot rolling process makes the steel tough and able to handle stress. These bars are safe and reliable for big projects.

Easy to Shape and Stretch

Hot rolled steel bars can stretch and bend easily. Stretching without breaking is called ductility. Bending into shapes is called malleability. These features make the bars useful for many jobs. You can cut or shape them into parts for tools or machines.

Tests check these features to ensure good quality. Below is a table showing two common tests:

| Test Type | What It Measures |

|---|---|

| Stretch Percentage | How much the metal stretches compared to its original length. |

| Narrowest Cross-Section | The smallest part of the metal after it breaks. |

These tests show the bars can bend and stretch a lot. This makes them useful for many different tasks.

Surface Features

Rough Texture

Hot rolled steel bars have a rough surface. This happens when the steel cools in the air. The roughness helps paint or coatings stick better. It works well for jobs where looks don’t matter, like concrete reinforcements.

Oxidation Layer

The high heat during making causes a thin rust layer. This layer is called scale and forms on the surface. It can protect the steel for a short time. For some uses, the scale needs to be cleaned off. Methods like pickling or sandblasting can remove it. Even with the scale, the steel stays strong inside. This keeps it dependable for many uses.

Cost-Effectiveness and Availability

Hot rolled steel bars are strong and affordable. They are a top choice for industries needing lots of tough materials. These bars are great for projects that need strength and flexibility without costing too much.

Making hot rolled steel bars is cheaper because of how they are made. The steel is heated very hot and shaped while soft. This uses less energy and fewer steps than cold rolling, which needs extra work for smoothness and precision. Because of this, hot rolled steel bars cost less and are perfect for big projects like buildings and roads.

Another benefit is how easy they are to find. In 2023, the market for these bars was worth $100 billion. By 2032, it might grow to $165 billion, with a yearly growth of 5.5%. This shows more people need them for building and car-making as cities grow. You can get these bars in many sizes and types to fit your project needs.

Hot rolled steel bars are also very useful. They work well for jobs where smooth surfaces and exact sizes don’t matter. This makes them great for building parts, support bars, and big machines. Since they are used so much, they are always in stock, helping you avoid project delays.

Advantages of Hot Rolled Steel Bars

Versatility in Applications

Hot rolled steel bars are very useful in many industries. They are used in construction, farming, mining, energy, and factories. Their strength, flexibility, and low cost make them fit for many jobs.

For example, in construction, they are used for beams and columns. In factories, they help make car parts and machines. Miners use them to support tunnels and build tools. Farmers use them in tractors and other farm machines.

| Industry | Uses |

|---|---|

| Construction | Beams, columns, and concrete support. |

| Manufacturing | Car parts, machines, and tools. |

| Mining | Tunnel supports and machine parts. |

| Energy | Power plant structures and oil/gas tools. |

| Agriculture | Tractor and farm machine parts. |

This makes hot rolled steel bars a trusted choice for many industries.

Ease of Shaping and Fabrication

Hot rolled steel bars are easy to shape and work with. You can bend, cut, or weld them without breaking. This makes them great for making custom parts.

The high heat during making softens the steel. This helps it take big or complex shapes. It also costs less to make than cold rolled steel.

- Cheaper to make than cold rolled steel.

- Flexible for shaping and building.

- Strong enough to bend and weld without breaking.

| Benefit | Details |

|---|---|

| Cost-Effective | Cheaper to make due to less energy and simpler steps. |

| Easy to Shape | High heat allows big and complex shapes. |

| Useful in Many Fields | Works in construction, cars, and heavy machines. |

These features make hot rolled steel bars a smart pick for many jobs.

Suitability for Large-Scale and Structural Uses

Hot rolled steel bars are strong and last a long time. They are perfect for big projects like buildings and bridges. They can handle heavy loads and impacts, making them great for structures.

They are also affordable, which helps with big budgets. You can use them for beams, columns, and other parts. They are easy to find, so your project won’t be delayed.

- Strong and durable, great for big structures.

- Used in buildings, bridges, and other large projects.

- Affordable and easy to get for beams and columns.

Using hot rolled steel bars keeps your big projects strong and on budget.

Applications of Hot Rolled Steel Bars

Construction Industry

Structural Beams and Columns

Hot rolled steel bars are very important in construction. They give strength to beams and columns, helping buildings and bridges stay strong. These bars are great for big projects like skyscrapers and bridges. Their toughness helps them handle heavy loads without breaking.

Many countries need more hot rolled steel bars as they build new roads and buildings. These bars are key for making safe and strong structures.

Reinforcement Bars for Concrete

Hot rolled steel bars make concrete stronger and less likely to crack. They stick well to concrete, creating a solid mix that lasts long. Projects like highways and bridges use these bars a lot. Their rough surface helps them grip the concrete tightly, making structures safer.

- Hot rolled steel bars help make concrete strong for big projects.

- They are also used in homes to keep them safe.

- More people are using these bars because they work so well.

Automotive Industry

Chassis and Frames

Car makers use hot rolled steel bars to make chassis and frames. These parts need to be strong but not too heavy. Flat steel bars are perfect for this job. They help cars stay safe and use less fuel.

- Hot rolled steel bars are used for car frames and axles.

- Electric cars need strong materials, so these bars are in demand.

- These bars are great for handling stress and staying strong.

Engine and Suspension Components

Hot rolled steel bars are also used in car engines and suspension systems. They are strong and bendable, which is good for moving parts. Suspension systems use these bars to absorb shocks and keep cars steady. As more electric cars are made, the need for these bars grows.

Agriculture and Heavy Equipment

Machinery and Tools

Farm machines like tractors and plows use hot rolled steel bars. These bars are tough and can handle rough conditions. Farmers like them because they last long and need less fixing.

- Hot rolled steel bars are used in farm tools and machines.

- They are strong enough for hard jobs on farms.

- Farmers save money because these bars don’t break easily.

Equipment Frames

Hot rolled steel bars are also used to make frames for heavy machines. These frames need to hold a lot of weight and work all the time. The bars are strong and easy to shape, making them perfect for this. Machines like bulldozers and harvesters rely on these bars for support.

Farmers and builders use hot rolled steel bars because they are strong and last long. These bars help make machines and tools that work well for tough jobs.

Energy Sector

Pipelines and Infrastructure

Hot rolled steel bars are important for energy systems. They are used in pipelines that carry oil, gas, and other materials. These bars are strong and can handle high pressure and tough conditions. Their strength keeps energy systems safe and working well.

In oil and gas work, round steel bars help build rigs and other structures. They hold heavy weights and handle impacts, making them reliable. Power plants also use these bars for strong parts. As the energy industry grows, more of these bars are needed.

- Flat steel bars are used in pipelines and oil rigs.

- Round bars are key for oil and gas systems.

- Power plants need these bars for their strength.

Renewable Energy Components

Renewable energy projects need hot rolled steel bars more than ever. Wind turbines use flat steel bars to stay strong in bad weather. These bars are easy to shape, which helps make complex turbine parts.

Wind farms and solar projects are increasing the demand for these bars. Solar panel mounts also use them for support. Their low cost and flexibility make them great for green energy projects.

- Wind turbines need flat steel bars for strength.

- Solar panels use these bars for support.

- Renewable energy growth is boosting demand for these bars.

General Manufacturing

Industrial Equipment

Hot rolled steel bars are crucial for making industrial machines. They are strong and last long, perfect for heavy-duty tools. These bars are used in mining and construction machines. They can carry heavy loads and resist damage, ensuring they last.

Their rough surface makes them easy to weld and shape. This helps create custom parts for special machines. From conveyor frames to machine parts, these bars are dependable.

- Used in mining and construction machines.

- Strong and durable for heavy equipment.

- Easy to weld and shape for custom parts.

Custom Fabrications

Hot rolled steel bars are great for making custom designs. They can bend into complex shapes without losing strength. This makes them useful for unique structures and parts.

In building projects, these bars are used for beams, columns, and concrete reinforcements. They can handle heavy weights and impacts, keeping structures safe. These bars are also used in concrete to add strength and prevent cracks.

- Used in beams, columns, and reinforced concrete.

- Great for making unique and complex designs.

- Add strength and safety to custom projects.

Hot rolled steel bars are flexible and strong materials. They are essential for modern energy and manufacturing industries.

Factors to Think About When Picking Hot Rolled Steel Bars

When choosing hot rolled steel bars, think about key factors. These help make sure the material fits your project and works well.

Needs for Your Project

First, know what your project needs. Different jobs need different features like strength or bending ability. For example, building projects need bars that hold heavy weight. Factory work might need bars that are easy to shape or weld.

Here’s how to pick the right steel bars:

- List what your project needs, like strength or rust resistance.

- Pick a steel grade that matches your needs. For example, C1010 is easy to shape, while C1045 is stronger.

- Think about how easy it is to cut, weld, or shape the bars. Hot rolled steel is usually easier to work with than cold rolled steel.

By focusing on these steps, you’ll pick steel bars that work well for your project.

Grades and Rules

Steel grades and rules decide how good and useful the bars are. Always check if the steel meets rules like ASTM or EN standards. These rules make sure the steel is safe and strong.

Different grades have different uses. Low-carbon steel like A36 is good for general building. High-carbon steel is stronger for tougher jobs. Always check labels to make sure the steel fits your project’s needs.

Price and Supply

Price and availability matter when picking steel bars. Market changes can affect costs and delivery times.

The table below shows how market trends affect price and supply:

| Market Trend Description | Effect on Price and Supply |

|---|---|

| More construction and factory work needing steel bars | Higher demand raises prices and lowers availability. |

| Eco-friendly production methods | Can lower costs by making production more efficient. |

| Problems in global supply chains and raw material price changes | Makes prices and availability less certain. |

To handle these issues, plan ahead and use trusted suppliers. Buying in bulk or locally can save money and avoid delays. By knowing market trends, you can make better choices and keep your project on schedule.

Picking the right hot rolled steel bars means balancing cost, quality, and performance. Careful planning helps your project succeed.

Future Trends in Hot Rolled Steel Bars

New Ways to Make Steel Bars

Making hot rolled steel bars is getting better with new tools. Machines called automated rolling mills are speeding up the process. These machines make fewer mistakes and work faster. They also help create bars with exact sizes. AI technology is now used to check quality during production. This ensures the bars are strong and well-made.

Factories are also using less energy to make steel bars. This saves money and helps the environment. Better rolling methods are making bar sizes more accurate. Special heat treatments are making the bars stronger and tougher.

- Rolling machines work faster and make fewer mistakes.

- AI checks quality to ensure strong steel bars.

- Energy-saving methods cut costs and help the planet.

These changes make hot rolled steel bars better and cheaper for your projects.

Eco-Friendly Steel Production

Steel makers now focus on saving energy and reducing waste. Many factories use recycled steel to make new bars. This helps the environment by cutting down on trash.

For example, some companies follow strict green rules like ISO 14025. These rules show they care about the planet. Buying steel from these companies supports eco-friendly choices.

- Using less energy lowers pollution.

- Recycled steel helps reduce waste.

- Green certifications prove eco-friendly practices.

Steel bars made from recycled materials are becoming popular. They are a smart choice for building and factory jobs. As more people want green materials, you’ll see more options available.

New Uses in Growing Industries

Hot rolled steel bars are now used in new industries. Electric cars (EVs) need these bars for special parts. Developing countries also need more steel bars for big building projects.

The table below shows new uses for steel bars:

| Where They’re Used | How They’re Used |

|---|---|

| Everyday Products | Used to make many items we use daily. |

| Farm Machines | Important for tools and machines that help grow food. |

| Big Building Projects | Needed for bridges, roads, and other large structures. |

| Electric Cars | Used in parts for modern electric vehicles. |

| Construction Jobs | Helps make concrete stronger and safer. |

These new uses show how helpful hot rolled steel bars are. As industries grow, these bars will be needed even more.

Hot rolled steel bars are strong, flexible, and affordable. They are used in many areas like building, cars, and factories. Their easy shaping makes them a top pick for modern jobs.

The table below shows their role in different industries:

| Industry | Use | Demand Level |

|---|---|---|

| Construction | Needed for strong buildings and bridges | High |

| Automotive | Important for making cars, including electric ones | Big |

| Industrial | Used for tools and machines as factories grow | Large |

Knowing about hot rolled steel bars helps you choose wisely. This ensures your projects are strong, efficient, and dependable.

FAQ

What makes hot rolled steel bars different from cold rolled steel bars?

Hot rolled steel bars are shaped when very hot. This makes them cheaper and easier to use. Cold rolled steel bars are made at room temperature. They have a smoother surface and are more precise.

Can you use hot rolled steel bars for outdoor projects?

Yes, they can be used outside. But their rough surface and rust layer might need extra coatings. These coatings help stop rust and make them last longer in bad weather.

How do you choose the right grade of hot rolled steel bars?

Think about what your project needs, like strength or flexibility. For example, A36 is good for general building. Stronger grades work better for heavy-duty jobs. Always check rules like ASTM or EN for guidance.

Are hot rolled steel bars eco-friendly?

Yes, they can be. Many makers use recycled steel and save energy during production. Look for certifications like ISO 14025 to ensure they meet green standards.

Why are hot rolled steel bars cost-effective?

Making them takes fewer steps and less energy than cold rolled steel. This lowers costs, making them great for big projects like bridges and buildings.

Can you weld hot rolled steel bars easily?

Yes, they are easy to weld because they bend well. Their rough surface helps make strong welds. Cleaning the rust layer first gives better results.

What industries rely on hot rolled steel bars the most?

Construction, car-making, and energy industries use them a lot. They are used for beams, car frames, pipelines, and wind turbines. Their flexibility makes them useful in many areas.

How do you maintain hot rolled steel bars?

Keep them in a dry place to stop rust. Add coatings or paint to protect them. Check them often to find and fix any damage.

💡 Tip: Talk to a supplier or expert to pick the best steel bars for your project.