What is C Channel Steel and How is it Used in Construction

Share

Table Of Content

Table Of Content

What is C Channel Steel and How is it Used in Construction

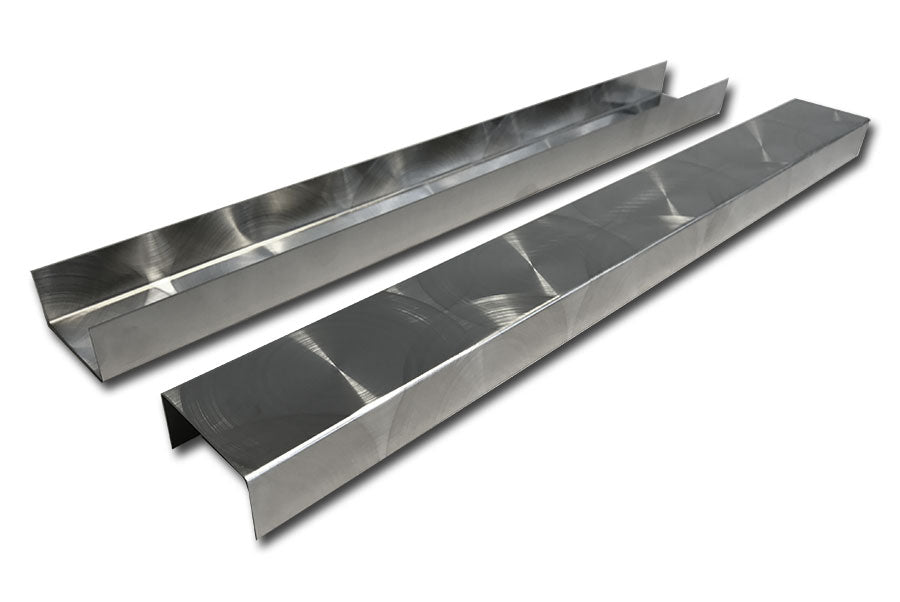

C channel steel, named for its distinctive C-shaped cross-section, is a vital material in construction and engineering. Its design provides excellent strength and stability, making it ideal for structural support in walls, roofs, and floors. You’ll also find it in bridge construction, where it reinforces decks and trusses to ensure efficient load distribution. This material’s versatility extends to industrial equipment, fencing, and even custom fabrications. Its ability to resist bending and shear forces makes it a reliable choice for projects requiring durability and precision.

Key Takeaways

- C channel steel has a C-shape that gives it strength and stability.

- It is flexible and used for walls, roofs, and bridges.

- Types like galvanized and stainless steel resist rust for outdoor use.

- It is strong but light, saving money on materials and transport.

- Picking the right type means checking weight needs and conditions.

- Adding coatings and doing upkeep can make it last longer.

- Structural engineers can help you pick the safest and best option.

- It can be recycled, helping the environment and saving resources.

Key Features of C Channel Steel

Shape and Design

The unique C-shaped design of c channel steel plays a critical role in its structural performance. This shape consists of a vertical web and horizontal flanges. The vertical web acts as the primary load carrier, effectively handling shear forces and providing strength in demanding applications like bridge construction. The horizontal flanges resist bending forces and offer surfaces for mounting, bolting, or welding. This design ensures stability and simplifies assembly.

The C-channel’s shape not only enhances its strength but also minimizes material usage. This makes it a cost-effective solution for various construction needs. Whether you’re working on a building frame or an industrial project, the design ensures efficient load distribution and reliable performance.

Material Composition

C channel steel is made from different materials, each offering unique properties suited to specific applications. The table below highlights the most common materials and their characteristics:

| Material | Properties | Applications |

|---|---|---|

| Carbon Steel | Excellent strength, widely used in indoor applications | Machinery, warehouse shelving |

| Galvanized Steel | Coated with zinc for corrosion resistance | Outdoor structures like bridges or fences |

| Stainless Steel | Resistant to rust and corrosion, ideal for marine and chemical industries | Chemical processing plants, coastal installations |

Carbon steel provides exceptional strength, making it ideal for indoor use. Galvanized steel, with its zinc coating, offers corrosion resistance, making it perfect for outdoor structures. Stainless steel, known for its rust resistance, is often used in marine environments or chemical industries. By choosing the right material, you can ensure the durability and efficiency of your project.

Strength and Load-Bearing Capacity

C channel steel is renowned for its impressive strength and ability to bear heavy loads. Its load-bearing capacity depends on its size and weight. For example, a C15 x 50 channel has a depth of 15 inches and weighs 50 pounds per foot, making it suitable for large-scale projects. On the other hand, a smaller C10 x 15.3 channel, with a depth of 10 inches and a weight of 15.3 pounds per foot, is better suited for lighter applications.

| Designation | Area (in²) | Depth (in) | Weight (lb/ft) |

|---|---|---|---|

| C15 x 50 | 14.7 | 15.00 | 50 |

| C15 x 40 | 11.8 | 15.00 | 40 |

| C15 x 33.9 | 9.96 | 15.00 | 33.9 |

| C12 x 30 | 8.82 | 12.00 | 30 |

| C12 x 25 | 7.35 | 12.00 | 25 |

| C12 x 20.7 | 6.09 | 12.00 | 20.7 |

| C10 x 30 | 8.82 | 10.00 | 30 |

| C10 x 25 | 7.35 | 10.00 | 25 |

| C10 x 20 | 5.88 | 10.00 | 20 |

| C10 x 15.3 | 4.49 | 10.00 | 15.3 |

| C9 x 20 | 5.88 | 9.00 | 20 |

When selecting c channel steel, you should consider the load requirements of your project. Larger channels handle heavier loads, while smaller ones are more suitable for lighter tasks. This versatility makes c channel steel a reliable choice for a wide range of construction applications.

Corrosion Resistance and Durability

When you choose materials for construction, durability often becomes a top priority. C channel steel stands out because of its excellent resistance to corrosion and its long-lasting performance. This feature makes it a reliable option for projects exposed to harsh environments, such as coastal areas, industrial zones, or regions with extreme weather conditions.

Corrosion resistance in c channel steel depends on the material and coating used. For example:

- Galvanized steel: A zinc coating protects the steel from rust and oxidation. This type works well for outdoor applications like bridges, fences, and roofing systems.

- Stainless steel: Its chromium content forms a protective layer that resists rust and chemical damage. This makes it ideal for marine environments or chemical processing plants.

Tip: If your project involves exposure to moisture, chemicals, or saltwater, consider using stainless or galvanized c channel steel for maximum durability.

The durability of c channel steel also comes from its structural integrity. Its C-shaped design not only provides strength but also reduces the risk of deformation over time. This ensures that your structures remain stable and secure, even under heavy loads or challenging conditions. Additionally, the material requires minimal maintenance, saving you time and money in the long run.

Another advantage is its ability to withstand temperature fluctuations. Whether it’s freezing winters or scorching summers, c channel steel maintains its performance without cracking or warping. This makes it a dependable choice for both indoor and outdoor projects.

To extend the lifespan of your c channel steel, you can apply protective coatings or paints. These add an extra layer of defense against environmental factors. Regular inspections and cleaning also help prevent the buildup of dirt or corrosive substances, ensuring the material stays in top condition.

By selecting the right type of c channel steel and taking proper care of it, you can create structures that last for decades. Its combination of corrosion resistance and durability makes it a smart investment for any construction project.

Best Quality Metal Products of Ansteel (China)

Types of C Channel Steel

C channel steel comes in various types, each designed to meet specific construction needs. Understanding these types helps you choose the right material for your project.

Plain C Channel Steel

Plain C channel steel is the most basic form of this material. It is made from untreated carbon steel, which provides excellent strength and versatility. This type is commonly used in indoor applications where exposure to moisture or corrosive elements is minimal. You might find it in machinery frames, shelving units, or interior structural supports.

However, plain C channel steel has lower resistance to rust and corrosion compared to other types. This makes it less suitable for outdoor or high-moisture environments. If your project involves such conditions, you may need to consider alternatives like galvanized or stainless steel channels.

Galvanized C Channel Steel

Galvanized C channel steel is coated with a layer of zinc, which significantly enhances its corrosion resistance. This type is ideal for outdoor applications, such as bridges, fences, or roofing systems, where exposure to moisture and weather elements is unavoidable. The zinc coating acts as a protective barrier, preventing rust and extending the material's lifespan.

To better understand the difference between plain and galvanized C channel steel, refer to the table below:

| Type of Steel | Corrosion Resistance |

|---|---|

| Plain C Channel | Lower resistance to rust and corrosion |

| Galvanized C Channel | High resistance due to zinc coating, ideal for outdoor use |

If you need a durable and cost-effective solution for outdoor projects, galvanized C channel steel is a reliable choice.

Stainless Steel C Channels

Stainless steel C channels offer superior performance in terms of strength, durability, and corrosion resistance. These channels are made from stainless steel, which contains chromium. This element forms a protective layer that resists rust, even in harsh environments like coastal areas or chemical processing plants.

Stainless steel C channels also provide additional benefits, as shown in the table below:

| Advantage | Description |

|---|---|

| Strength-to-Weight benefits | Provides a better strength-to-weight ratio than some other forms of metal. |

| Corrosion resistance | Suitable for various applications including process plants, water, acids, and alkaline solutions. |

| Sanitation | Ideal for high-hygiene environments like hospitals and food processing plants due to ease of cleaning. |

| Resistance to fire and heat | Resists scaling and maintains heat resistance. |

These features make stainless steel C channels an excellent choice for projects requiring high hygiene standards, such as hospitals or food processing facilities. They are also well-suited for environments with extreme temperatures or chemical exposure.

By understanding the unique properties of each type of C channel steel, you can select the one that best fits your project's requirements.

Custom or Specialized C Channels

Custom or specialized C channels are tailored to meet the unique demands of specific industries or projects. These channels go beyond standard designs, offering enhanced functionality and precision for specialized applications. If your project has unique structural or design requirements, custom C channels can provide the perfect solution.

You might encounter custom C channels in industries where standard options fall short. For example:

- Construction: Reinforced profiles are often used in earthquake-resistant structures or high-rise buildings. These channels provide additional strength and stability to withstand extreme forces.

- Transportation: Lightweight, precision-shaped channels are essential for vehicle frames and railcars. They help reduce weight while maintaining structural integrity.

- Renewable Energy: Mounting systems for solar panels or wind turbines frequently require custom profiles. These channels ensure proper alignment and secure installation in challenging environments.

- Industrial Equipment: Machinery supports, conveyor systems, and protective enclosures often rely on custom C channels. These profiles enhance durability and fit seamlessly into complex designs.

Custom C channels are manufactured using advanced techniques like laser cutting, CNC machining, or roll forming. These methods allow for precise shaping and sizing, ensuring the channels meet your exact specifications. You can choose from various materials, including carbon steel, stainless steel, or galvanized steel, depending on your project's needs. For instance, stainless steel might be ideal for environments with high humidity or chemical exposure, while galvanized steel works well for outdoor applications.

Tip: When designing custom C channels, consider factors like load requirements, environmental conditions, and compatibility with other materials. Collaborating with engineers or manufacturers can help you achieve the best results.

The versatility of custom C channels makes them a valuable asset in modern construction and engineering. Whether you need a unique shape, enhanced strength, or specific material properties, these channels can adapt to your requirements. By investing in custom solutions, you ensure your project meets both functional and aesthetic goals.

Applications of C Channel Steel in Construction

Structural Support

C channel steel plays a crucial role in providing structural support across various construction projects. Its high strength and load-bearing capacity make it a reliable choice for creating sturdy frameworks. You can find it in applications such as:

- Wall Studs: Used to build strong frameworks for walls in residential and commercial buildings.

- Roof Trusses: Ideal for spanning long distances in large-scale roofing systems.

- Floor Joists: Commonly used in lightweight steel frame constructions to support heavy loads.

- Bridge Decks and Trusses: Ensures efficient load distribution and stability in bridge construction.

- Infrastructure Reinforcement: Provides long-term stability in culverts, tunnels, and retaining walls.

- Frameworks for Equipment: Used in constructing industrial machine frameworks and conveyor systems.

- Custom Fabrications: Tailored to create specialized supports for unique machinery.

The versatility of c channel steel allows it to adapt to different structural needs. Whether you’re working on a bridge or an industrial facility, this material ensures durability and stability.

Framing and Partitioning

C channel steel is widely used in framing and partitioning systems due to its exceptional strength-to-weight ratio. This property provides strong support while keeping the overall weight of structures low. You’ll find this especially beneficial in projects where reducing material weight is essential for efficiency and cost-effectiveness.

Compared to wood or standard steel beams, c channel steel offers better load-bearing capacity for its weight. It can endure significant vertical and lateral forces without compromising its structural integrity. This makes it a preferred choice for both residential and commercial buildings. Whether you’re constructing interior partitions or framing large spaces, c channel steel ensures stability and long-lasting performance.

Roofing and Ceiling Systems

C channel steel is an excellent material for roofing and ceiling systems. Its strength and durability make it suitable for load-bearing applications, especially in large buildings or warehouses. The high strength-to-weight ratio allows for wider spacing between supports, reducing material costs and speeding up installation times.

You’ll appreciate how easy it is to install c channel steel in roofing systems. Its lightweight nature simplifies handling, while its structural integrity ensures safety and reliability. This combination of features makes it a cost-effective and efficient solution for expansive roof spans. Whether you’re working on a commercial warehouse or a residential project, c channel steel provides the support you need without compromising quality.

Bridges and Infrastructure Projects

C channel steel plays a vital role in bridges and infrastructure projects due to its exceptional strength and versatility. You’ll find it indispensable in components that endure significant stress, such as bridge decks and trusses. Its high load-bearing capacity ensures efficient distribution of heavy traffic loads, making it a reliable choice for large-scale infrastructure.

Here are some key ways c channel steel contributes to these projects:

- Provides critical support for bridge decks, ensuring stability under heavy loads.

- Distributes forces effectively, reducing stress on individual components.

- Offers durability and resilience, even in harsh environments.

- Facilitates faster installation due to its lighter weight, saving time and labor costs.

- Galvanized variants resist corrosion, extending the lifespan of structures.

- Reinforces tunnels, culverts, and retaining walls, protecting against geological pressures.

When working on infrastructure projects, you can rely on c channel steel for its ability to withstand demanding conditions. Its combination of strength, durability, and ease of installation makes it a preferred material for engineers and builders.

Industrial Equipment and Machinery

C channel steel is a cornerstone in the construction of industrial equipment and machinery. Its structural integrity and adaptability make it ideal for various applications. Whether you’re designing machine frames or conveyor systems, this material ensures stability and precision.

The table below highlights common uses of c channel steel in industrial equipment:

| Type of Equipment | Description |

|---|---|

| Machine Frames | Used in constructing frames of industrial machinery for stability and support. |

| Conveyor Systems | Forms the backbone of conveyor systems, ensuring structural alignment. |

| Custom Supports | Provides specialized support for various machinery applications. |

You’ll notice that c channel steel offers both strength and flexibility, which are essential for industrial settings. For example, in conveyor systems, it ensures proper alignment and prevents structural failures. In custom supports, it adapts to unique machinery designs, providing tailored solutions for specific needs.

By incorporating c channel steel into your industrial projects, you can achieve reliable performance and long-lasting results. Its ability to handle heavy loads and resist wear makes it a valuable asset in manufacturing and engineering environments.

Best Quality Metal Products of Ansteel (China)

Benefits of Using C Channel Steel

High Strength-to-Weight Ratio

C channel steel offers an outstanding strength-to-weight ratio, making it a preferred material for many construction projects. Its design allows it to support heavy loads without adding unnecessary weight. This feature is especially important in applications like bridges, where minimizing material weight is crucial for efficiency.

Here are some key advantages of its strength-to-weight ratio:

- It provides exceptional load-bearing capacity while keeping the material lightweight.

- Its open profile reduces material usage, making it more efficient than solid steel beams or concrete.

- It lowers transportation costs and simplifies installation, particularly in automotive and aerospace applications.

By choosing c channel steel, you can achieve a balance between strength and efficiency, ensuring your structures remain durable without becoming overly heavy.

Cost-Effectiveness

C channel steel strikes a perfect balance between affordability and performance. Its unique design enhances load-bearing capacity while reducing material usage. This ensures long-lasting performance without inflating costs. Compared to other structural materials, it provides a cost-effective solution for a wide range of applications.

For example, using c channel steel in your project can reduce both material and labor expenses. Its lightweight nature simplifies handling and installation, saving time and effort. Additionally, its durability minimizes the need for frequent repairs or replacements, further lowering long-term costs.

If you’re looking for a material that delivers strength and reliability without breaking the budget, c channel steel is an excellent choice.

Versatility in Design and Use

The versatility of c channel steel makes it suitable for various construction applications. Its unique shape and customizable features allow it to adapt to different project requirements. Whether you’re working on a residential building, an industrial facility, or a large-scale infrastructure project, this material can meet your needs.

| Design Feature | Description |

|---|---|

| Unique Shape | The C shape provides structural integrity and versatility in various applications. |

| Strength-to-Weight Ratio | Offers robust support while minimizing overall weight, crucial for efficiency in construction. |

| Surface Treatments | Enhances durability against environmental factors, ensuring longevity in various settings. |

| Customizable Hole Patterns | Allows for quick assembly and integration into larger systems, improving efficiency. |

| Advanced Manufacturing Processes | Enables customization and functional enhancements, expanding application possibilities. |

| Reinforcements and Inserts | Increases load-bearing capacity and resistance to deformation, suitable for heavy-duty applications. |

You can use c channel steel in framing, roofing, machinery, and even custom fabrications. Its adaptability ensures that it fits seamlessly into your project, regardless of complexity. By leveraging its design features, you can create efficient and durable structures tailored to your specific needs.

Long Lifespan and Low Maintenance

When you choose materials for construction, durability and maintenance often become top priorities. C channel steel stands out as a material that offers both a long lifespan and minimal upkeep. Its unique properties make it a reliable choice for projects that demand longevity and cost efficiency.

One of the key reasons for its durability is its resistance to environmental stress. Galvanized variants, for example, come with a zinc coating that protects the steel from corrosion. This feature ensures that the material performs well even in harsh conditions like coastal areas or industrial zones. You’ll find that this corrosion resistance significantly extends the lifespan of structures made with c channel steel.

Another advantage lies in its ability to withstand physical impacts and heavy loads. Whether used in tunnels, culverts, or retaining walls, c channel steel provides structural resilience. Its strength ensures that these components remain stable over time, reducing the need for frequent repairs. In industrial settings, it serves as a stable foundation for machinery frames, supporting heavy equipment without compromising performance.

You’ll also appreciate how c channel steel minimizes maintenance costs. Its durability means fewer repairs and replacements, saving you both time and money. For example, when used in fencing or barriers, it offers long-lasting protection against wear and tear. This makes it a popular choice for projects where reliability and low upkeep are essential.

The material’s versatility further enhances its value. You can use it in a wide range of applications, from industrial enclosures to structural reinforcements. Its ability to adapt to different environments and conditions ensures that it remains a dependable option for decades. By investing in c channel steel, you’re choosing a material that combines strength, durability, and cost-effectiveness.

To maximize its lifespan, consider selecting the right type of c channel steel for your project. Galvanized or stainless steel options work best in environments with high moisture or chemical exposure. Regular inspections and occasional cleaning can also help maintain its condition, ensuring that your structures stay strong and secure for years to come.

Tip: For projects exposed to harsh weather or heavy loads, galvanized or stainless steel c channels provide the best long-term performance.

By choosing c channel steel, you’re not just building for today—you’re creating structures that will stand the test of time with minimal maintenance.

How to Choose the Right C Channel Steel

Selecting the right c channel steel for your project involves evaluating several critical factors. By understanding your requirements and the material's properties, you can ensure optimal performance and durability.

Assessing Load Requirements

The first step in choosing c channel steel is determining the load requirements of your project. This involves analyzing the forces the material will need to withstand, such as weight, tension, and shear. The table below outlines key factors to consider:

| Factor | Description |

|---|---|

| Strength and Durability | Typical tensile strength values range between 250 and 550 MPa, allowing it to withstand significant loads. |

| Dimensional Specifications | Web height, flange width, and thickness directly influence performance and load capacity. |

| Mechanical Performance | High strength-to-weight ratio and rigidity under load make C-channel steel ideal for various applications. |

You should match the channel's dimensions and strength to the specific demands of your project. For example, larger web heights and thicker flanges provide greater load-bearing capacity, making them suitable for heavy-duty applications like bridge construction or industrial equipment.

Tip: Always consult load charts or structural engineers to ensure the chosen c channel steel meets safety and performance standards.

Considering Environmental Factors

Environmental conditions play a significant role in determining the type of c channel steel you should use. Exposure to moisture, chemicals, or extreme temperatures can affect the material's performance and lifespan. For outdoor projects, galvanized steel with a zinc coating offers excellent corrosion resistance. In marine or chemical environments, stainless steel is a better choice due to its inherent rust resistance.

If your project involves high humidity or saltwater exposure, prioritize materials with protective coatings. For example, epoxy or powder coatings enhance resistance to weathering and chemical damage. These coatings add an extra layer of protection, ensuring the material remains durable over time.

Note: Consider the long-term environmental impact on the material. Choosing the right type of steel upfront can save you from costly repairs or replacements later.

Evaluating Material and Coating Options

The material and coating you select directly influence the performance and longevity of your c channel steel. Below is a table summarizing common options and their applications:

| Material Type | Key Properties | Applications |

|---|---|---|

| Cold-formed C-channel | Increased rigidity and dimensional accuracy | Precision applications like automotive frameworks |

| Hot-rolled C-channel | Easier customization and forming | General construction |

| Galvanized Steel | Zinc coating for corrosion resistance | Outdoor or marine environments |

| Stainless Steel | Inherent corrosion resistance | Chemical processing plants, coastal installations |

| Aluminum C-channel | Lightweight and corrosion-resistant | Transportation and architectural applications |

| Custom C-channel | Tailored dimensions and properties for specific project requirements | Unique project needs |

For outdoor applications, galvanized steel provides robust protection against rust. Stainless steel excels in chemically aggressive environments, while aluminum offers a lightweight alternative for transportation or architectural projects. Custom c channels allow you to tailor dimensions and properties to meet unique project specifications.

Tip: Evaluate the cost-effectiveness of each option. While stainless steel may have a higher upfront cost, its durability often makes it a more economical choice in the long run.

By carefully assessing load requirements, environmental factors, and material options, you can select the ideal c channel steel for your project. This ensures your structure remains strong, durable, and cost-effective.

Consulting with Structural Engineers

When working on a construction project, consulting with structural engineers is one of the smartest decisions you can make. These professionals bring expertise that ensures your project meets safety, durability, and performance standards. Their guidance helps you select the right type of C channel steel for your specific needs.

Why You Should Consult a Structural Engineer

Structural engineers analyze the unique requirements of your project. They consider factors like load-bearing capacity, environmental conditions, and material compatibility. This ensures that the C channel steel you choose can handle the demands of your structure. Without their input, you risk selecting materials that may not perform as expected, leading to costly repairs or safety issues.

Tip: Always involve a structural engineer during the planning phase. Early consultation can save you time and money by preventing design errors.

What Structural Engineers Evaluate

Structural engineers focus on several critical aspects when recommending C channel steel. Here’s what they typically assess:

- Load Requirements: They calculate the forces your structure will face, such as weight, tension, and shear.

- Material Properties: They evaluate the strength, corrosion resistance, and durability of different steel types.

- Environmental Factors: They consider exposure to moisture, chemicals, or extreme temperatures.

- Design Specifications: They ensure the dimensions and shape of the C channel steel align with your project’s design.

By addressing these factors, structural engineers help you make informed decisions that enhance the safety and longevity of your construction.

Benefits of Professional Guidance

Working with a structural engineer offers several advantages:

- Safety Assurance: Engineers ensure your structure complies with building codes and safety standards.

- Cost Efficiency: Their recommendations help you avoid over-engineering or under-engineering, saving material and labor costs.

- Optimized Performance: They select materials that maximize strength and durability while minimizing weight.

Note: Structural engineers also provide detailed reports and calculations, which can be essential for obtaining permits or approvals.

How to Collaborate Effectively

To get the most out of your consultation, prepare the following information:

- Project blueprints or sketches.

- Details about the intended use of the structure.

- Information about the environment where the structure will be built.

Sharing these details allows the engineer to provide tailored advice that aligns with your goals.

By consulting with structural engineers, you gain the confidence that your project will stand the test of time. Their expertise ensures that every piece of C channel steel you use contributes to a safe, efficient, and durable structure.

C channel steel stands out as a versatile and reliable material in construction. Its C-shaped profile provides strength and efficiency, resisting bending and shear forces. You’ll find it used in applications ranging from support beams in buildings to structural reinforcement in bridges. Its high tensile strength and resistance to deformation make it ideal for carrying heavy loads, even in harsh environments. Additionally, its strength-to-weight ratio promotes cost-effective construction, while its corrosion resistance ensures longevity. Whether you’re framing, reinforcing, or fabricating custom structures, c channel steel offers a dependable solution for your needs.

Best Quality Metal Products of Ansteel (China)

FAQ

What is the difference between C channel steel and I-beam steel?

C channel steel has a C-shaped cross-section, while I-beam steel has an "I" shape. C channels are lighter and better for smaller projects or framing. I-beams handle heavier loads and are used in large-scale construction like bridges or skyscrapers.

Can you cut or customize C channel steel?

Yes, you can cut and customize C channel steel to fit your project. Manufacturers use techniques like laser cutting or CNC machining for precise dimensions. Always consult professionals to ensure the modifications meet safety and structural requirements.

How do you prevent C channel steel from rusting?

Choose galvanized or stainless steel for rust resistance. For plain steel, apply protective coatings like paint or powder. Regular maintenance, such as cleaning and inspections, also helps prevent rust in harsh environments.

Is C channel steel suitable for outdoor use?

Yes, galvanized or stainless steel C channels work well outdoors. Galvanized steel resists rust with its zinc coating, while stainless steel withstands moisture and chemicals. These options ensure durability in outdoor conditions like rain or humidity.

How do you calculate the load capacity of C channel steel?

You calculate load capacity by considering the channel's size, material, and application. Use load charts or consult a structural engineer for accurate calculations. This ensures the steel can handle the required weight safely.

What tools do you need to install C channel steel?

You’ll need basic tools like drills, bolts, and welding equipment for installation. For precise cuts, use saws or laser cutters. Always follow safety guidelines and use proper protective gear during installation.

Can you recycle C channel steel?

Yes, C channel steel is recyclable. Steel retains its properties after recycling, making it an eco-friendly choice. Recycling reduces waste and supports sustainable construction practices.

What industries commonly use C channel steel?

C channel steel is widely used in construction, transportation, and manufacturing. You’ll find it in building frames, bridges, machinery, and even renewable energy projects like solar panel mounts. Its versatility makes it valuable across industries.

Best Quality Metal Products of Ansteel (China)