What Are Cold Rolled Steel Bars and Their Key Applications

Share

Table Of Content

Table Of Content

Cold rolled steel bars are made and shaped without heat. They are strong, precise, and have a smooth surface. These bars are very important in many industries like building, cars, and making machines. For example:

- Car makers use them for strong parts as more cars are built.

- Builders use them to make structures stronger, especially in growing cities.

- Machine makers like them because they are easy to shape for exact parts.

Their usefulness and dependability make them a key part of modern industries.

Key Takeaways

- Cold rolled steel bars are made without heat. This makes them stronger and more accurate than hot rolled steel.

- These bars are useful in many industries like building, cars, and everyday products.

- Their smooth surface and exact size make them great for jobs needing precise measurements.

- Cold rolled steel bars make products last longer, so they are good for hard tasks.

- To stop rust, cover cold rolled steel with coatings, especially outside.

Understanding Cold Rolled Steel Bars

What Is a Cold Rolled Steel Bar?

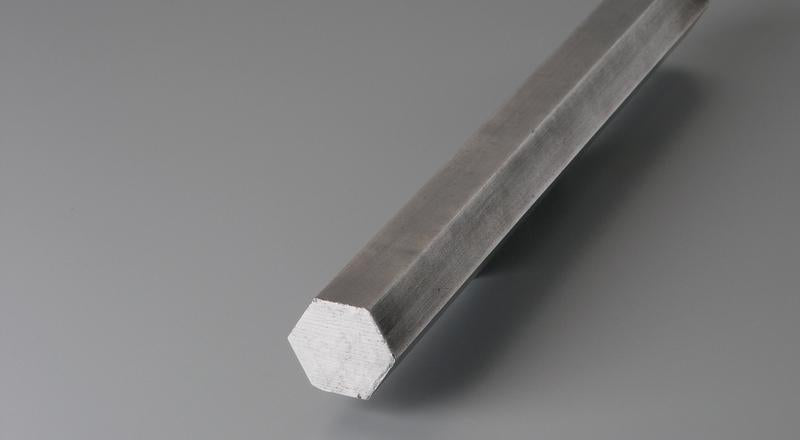

A cold rolled steel bar is steel shaped without heat. Unlike hot rolled steel, it is made at room temperature. This process makes it stronger and more precise. It also gives the steel a smooth surface.

These bars are known for being accurate and smooth. They come in different hardness levels like full-hard, half-hard, and quarter-hard. This makes them useful for many jobs. You’ll see them in construction, cars, and factories where strength matters.

Some important features include:

- Greater Tolerances: These bars are thinner but stay strong.

- Easily Mouldable: They can be shaped for many projects.

- Applications: Used in bridges, appliances, furniture, and airplane parts.

How Cold Rolled Steel Bars Differ from Other Steel Types

Comparison with Hot Rolled Steel

Cold rolled steel bars are very different from hot rolled steel. The cold rolling process makes them 20% stronger. This makes them great for tough jobs. They also have a smoother surface and are more precise. Hot rolled steel is cheaper but less refined.

For example:

- Cold rolled steel feels smooth and slightly oily.

- Its bars are straight with sharp edges.

- Tubes have better shape and evenness.

Comparison with Other Steel Products

Cold rolled steel bars are more precise than other steel products. They are used for exact parts like gears and shafts. The cold rolling process makes them stronger for tough tasks.

But, they cost more because of extra work. Some grades are less bendable, limiting their use. Still, their high quality and flexibility make them popular in many industries.

The Manufacturing Process of Cold Rolled Steel Bars

Overview of the Cold Rolling Process

Getting Steel Ready

The process starts by picking and checking raw steel. The steel must be clean and free of flaws. This step ensures the final product is high quality. After inspection, the steel is cleaned to remove rust or oil. This makes it ready for the cold rolling process.

Rolling and Shaping Without Heat

Cold rolling happens at normal room temperature. The steel goes through rollers to make it thinner. Each pass makes the steel stronger and smoother. The process has many steps with different speeds and thickness changes. For example:

| Rolling Stage | Thickness Change | Speed (m/min) | Temperature (°C) |

|---|---|---|---|

| First Pass | 20-30% | 800-1000 | 20-40 |

| Middle Pass | 15-25% | 600-800 | 30-50 |

| Last Pass | 5-10% | 400-600 | 25-35 |

This careful process makes the steel strong and smooth without losing quality.

Key Parts of the Process

Keeping Temperature Steady

Temperature control is very important in cold rolling. Even though it’s done at room temperature, steady conditions stop cracks or uneven steel. Special tools like roll bending and feedback systems help keep the steel precise. These tools make sure the steel’s size and shape are exact.

Smooth Surface and Accurate Size

Cold rolling improves the steel’s surface and size accuracy. It removes rough spots, leaving it smooth and shiny. Tools like X-ray gauges and sensors check the steel’s size. For example:

| Check Type | Tool Used | Accuracy Level |

|---|---|---|

| Thickness | X-ray gauge | ±0.001mm |

| Width | Optical sensor | ±0.1mm |

| Flatness | Stressometer | ±2 I-units |

These checks make sure the steel is perfect for things like car parts and building materials.

Key Properties and Benefits of Cold Rolled Steel Bars

Strength and Durability

Cold rolled steel bars are very strong and long-lasting. The cold rolling process makes them 20% stronger by hardening the steel. This strength is great for tough jobs that need reliable materials. For example, car parts like control arms and stabilizer bars use this strength. Steering parts, such as tie rods and knuckles, also depend on these features for accuracy and performance.

These steel bars can bend without breaking because they are flexible. This makes them useful for many hard tasks. Car parts made from these bars often get special coatings. These coatings protect them from rust, even in bad weather.

| Property | Description |

|---|---|

| Strength | Cold rolling makes steel 20% stronger through hardening. |

| Ductility | Flexibility allows bending without breaking. |

| Surface Quality | Smooth surface helps in many important uses. |

Precision and Dimensional Accuracy

Cold rolled steel bars are very precise and accurate in size. The way they are made gives them tighter measurements than other steel types. This makes them perfect for jobs needing exact sizes. For example, car parts like gears and shafts need this precision to work well.

Compared to hot rolled steel, cold rolled steel bars have smoother surfaces and better accuracy. Their neat and polished look makes them great for projects where looks and exactness are important.

| Feature | Cold Rolled Steel | Hot Rolled Steel |

|---|---|---|

| Surface Finish | Smoother and more exact | Rough and uneven |

| Dimensional Precision | More accurate sizes | Less exact sizes |

Superior Surface Finish

Cold rolled steel bars have a very smooth surface. The process makes the surface as smooth as 0.1μm Ra, which looks nice and feels polished. This is important for things like furniture or items that need to look good and work well.

They are also very exact in size, with tolerances as close as ±0.013mm. This means they fit perfectly in their intended use, saving time and effort on extra adjustments.

| Measurable Aspect | Value |

|---|---|

| Surface Roughness | As smooth as 0.1μm Ra |

| Dimensional Tolerance | ±0.013mm |

Cold rolled steel bars are strong, precise, and smooth. These qualities make them a trusted choice for building, cars, and factories.

Versatility for Different Uses

Cold rolled steel bars are useful in many industries. Their strength, accuracy, and smooth surface make them very versatile. These bars are used in building, cars, machines, and everyday items.

In building projects, these steel bars are key for strong parts. They are used in beams and columns to hold heavy weights. As cities grow, they are needed more for urban structures.

Car makers use these bars for strong and lasting parts. They are very important in electric cars, which need light but strong materials. Parts like axles, gears, and suspensions benefit from their precision.

Machine makers like these bars for exact parts. They are easy to shape into gears, bearings, and shafts. This helps machines work better and last longer.

For everyday items, these bars are both strong and good-looking. They are used in appliances, furniture, and electronics. Their smooth finish makes products look nice and stay durable.

| Industry | How They Are Used |

|---|---|

| Automotive | For strong, precise parts like gears and axles, especially in EVs. |

| Construction | Used in beams and columns to support buildings and urban growth. |

| Machinery & Equipment | Ideal for making exact parts like gears and shafts for better machine performance. |

| Consumer Goods | Found in furniture, appliances, and electronics for strength and polished looks. |

Cold rolled steel bars are flexible and meet many needs. Their role in different industries shows their value in today’s world.

Applications of Cold Rolled Steel Bars Across Industries

Construction Industry

Structural Frameworks and Support Beams

Cold rolled steel bars are very important in construction. They are used in frameworks and beams for strength and accuracy. These bars make buildings safer and last longer. As cities grow, the need for strong materials like these bars increases.

| Evidence Type | Description |

|---|---|

| Market Demand | More 1018 Cold Rolled Steel Bars are needed for growing cities and new projects. |

| Application | Used in construction to make structures stronger and safer. |

| Market Trends | Global building projects are driving demand for quality materials like cold rolled steel bars. |

Reinforcement in Concrete Structures

Cold rolled steel bars make concrete structures much stronger. They help concrete handle heavy loads and tough weather. These bars are often used in bridges and tall buildings. Engineers choose them because they are strong and last a long time.

Automotive Industry

Drive Shafts and Axles

The automotive industry depends on cold rolled steel bars. They are used to make drive shafts and axles, which need to be very strong. These parts face constant stress, and these bars provide the needed toughness.

- Cold rolled steel is strong, keeping drive shafts reliable.

- It lasts long, even with heavy use in vehicles.

- Its easy shaping allows for making detailed parts.

| Attribute | Description |

|---|---|

| Strength | High strength makes it perfect for drive shafts. |

| Durability | Long-lasting material for tough car parts. |

| Corrosion Resistance | Treated to avoid rust, making parts safer and durable. |

| Weight Reduction | Lighter parts improve fuel efficiency in cars. |

| Cost Efficiency | Affordable production makes it a smart choice. |

| Design Flexibility | Easy to shape for creative car designs. |

Gear Systems and Suspension Components

Cold rolled steel bars are great for gear systems and suspensions. Their exact size helps parts work smoothly and last longer. This is especially useful for electric cars, where every part must be efficient and reliable.

Appliances and Consumer Goods

Components in Home Appliances

Cold rolled steel bars are used in many home appliances. They are found in washing machines and refrigerators. Their smooth surface makes appliances look better and work well, which customers like.

Furniture and Decorative Items

These bars are also used in furniture and decorations. They are strong and look polished, making them great for modern designs. From chairs to picture frames, they add style and strength to products.

Market trends show more use of cold rolled steel bars in consumer goods. They are key in making not just appliances but also machines and tools. This shows their importance in today’s manufacturing world.

Manufacturing and Tooling

Cold rolled steel bars are important for making tools and machines. They are strong, smooth, and precise, which helps create quality parts. These bars make tools last longer and work accurately in tough jobs.

Gears, Bearings, and Shafts

Cold rolled steel bars are used in gears, bearings, and shafts. These parts need exact sizes and smooth surfaces to work well. Cold rolling makes the steel easier to shape into perfect pieces. This reduces damage and helps machines last longer.

For example, car gears and shafts made from these bars improve how cars run. Their strength handles stress, and their smoothness lowers friction. Bearings made from these bars help machines move smoothly and stay reliable.

| Industry Sector | How They Are Used | Benefits |

|---|---|---|

| Automotive | Making strong and precise car parts. | Strength, durability, easy to shape |

| Machinery and Equipment | Creating exact parts with smooth finishes. | Good machinability, strong properties |

Drill Bits and Cutting Tools

Cold rolled steel bars are great for drill bits and cutting tools. These tools need to be strong and resist wear to cut materials. Cold rolling makes the steel harder, which is perfect for these uses.

Drill bits made from these bars stay sharp after many uses. Cutting tools like saws and chisels are durable and make clean cuts. Their smooth finish means less sharpening is needed.

Cold rolled steel bars give tools the strength and accuracy they need. They are a reliable choice for industries that require high-quality parts.

Cold rolled steel bars are strong, accurate, and have smooth surfaces. These features make them dependable for tough jobs. They are used in industries like cars, buildings, and everyday products because they are so useful.

| Industry Sector | Where They Are Used | Why They Are Important |

|---|---|---|

| Automotive | Electric cars, lightweight car parts | Strong and durable materials for long-lasting performance |

| Machinery and Equipment | Exact parts, tools | Easy to shape and great for precise measurements |

| Consumer Goods | Home appliances, furniture, electronics | Look nice and work well for many uses |

These bars are perfect for today’s building and manufacturing needs. From tall buildings to detailed tools, they perform better than other materials.

FAQ

How are cold rolled steel bars different from hot rolled steel?

Cold rolled steel bars are stronger and more exact. They have smoother surfaces and tighter measurements. Hot rolled steel is rougher and less detailed. Use cold rolled steel when you need strength and precision.

Can cold rolled steel bars be used outside?

Yes, but they need protection. Cold rolled steel can rust if it gets wet. Adding paint or coatings stops rusting. For outdoor use, check if the steel is treated for weather.

Are cold rolled steel bars pricier than other steel types?

Yes, they cost more because of how they’re made. Their extra strength, smoothness, and accuracy make them worth it. If your project needs top-quality steel, they are a good choice.

Which industries use cold rolled steel bars the most?

Construction, car-making, and factories use these bars a lot. They add strength to buildings, precision to car parts, and durability to tools. Their flexibility makes them useful in many areas.

How do you take care of cold rolled steel bars?

Keep them dry and clean to stop rust. Store them in a dry place away from water. If they get wet, dry them quickly. Check them often to keep them in good shape for a long time.