20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

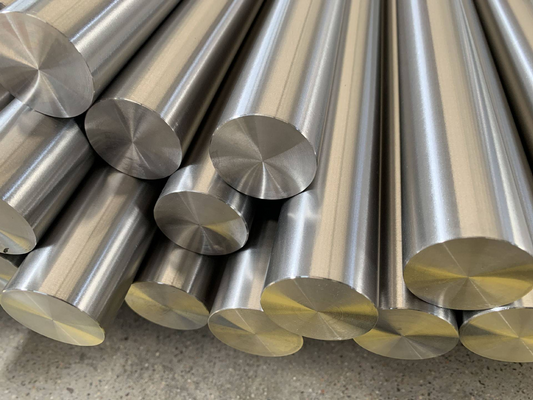

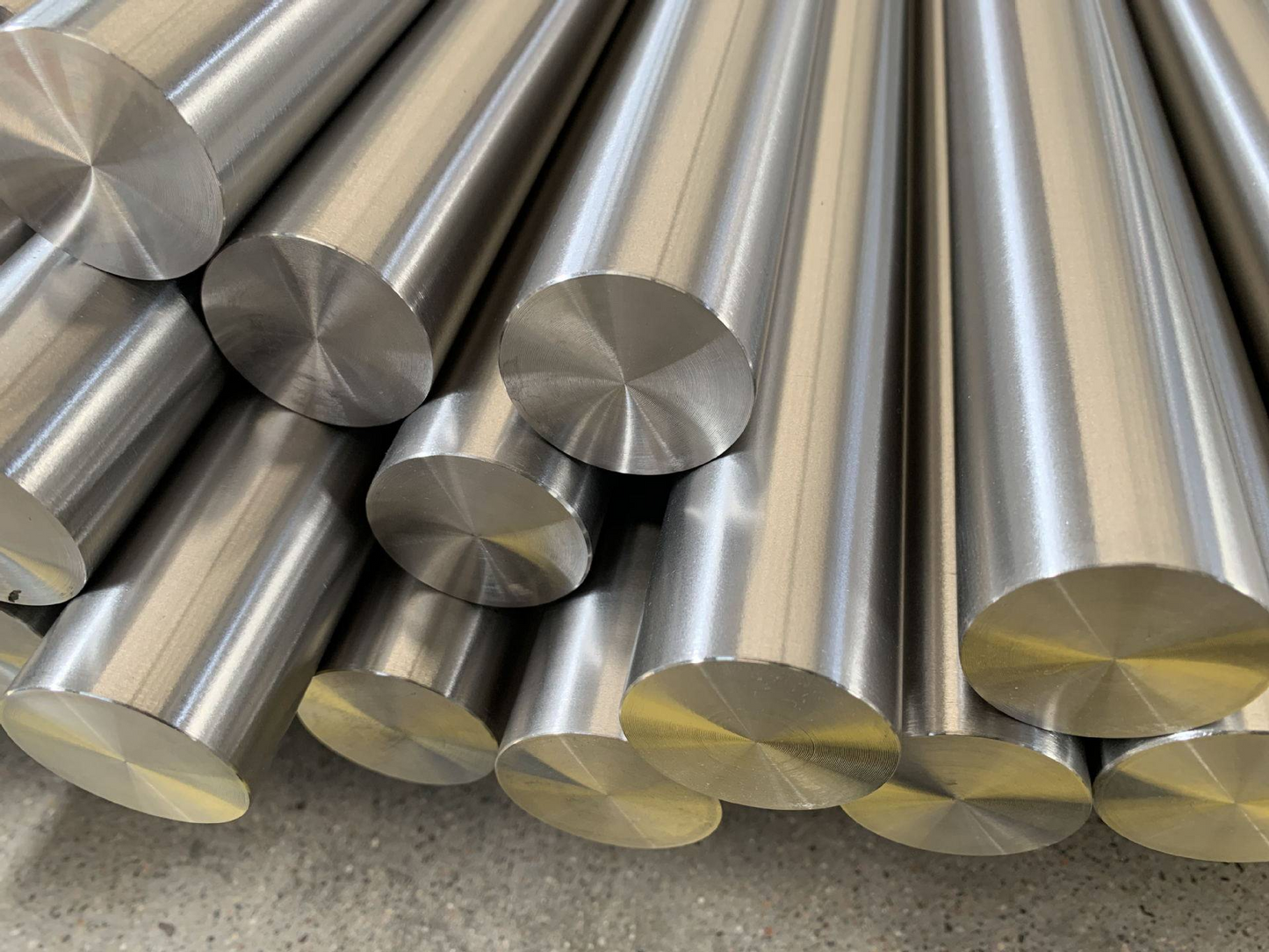

Product Overview

الخصائص المعدنية

EN L485 هو فولاذ مضاف إليه عناصر دقيقة يتميز بتركيب ميكروهيكلي من الفريت واللؤلؤة ذات الحبيبات الدقيقة التي تم تحقيقها من خلال الدرفلة المنضبطة والتبريد المعجل. يساهم إضافة النيوبيوم والفاناديوم في تعزيز الترسيب وتنقية الحبيبات، مما يؤدي إلى مزيج ممتاز من القوة والصلابة. يضمن المنخفض من مكافئ الكربون (CE ≤ 0.43%) قابلية لحام فائقة دون متطلبات تسخين مسبق.

عملية التصنيع

تستخدم MetalZenith تقنية المعالجة الحرارية الميكانيكية المتقدمة (TMCP)، حيث تجمع بين الدرفلة المنضبطة في مناطق إعادة بلورة الأوستينيت وغير إعادة البلورة تليها التبريد المعجل. تعمل هذه العملية على تحسين تحويل الأوستينيت إلى الفريت، مما يحقق أحجام حبيبات دقيقة (ASTM 10-12) وخصائص ميكانيكية متجانسة. تضمن مرافق الصب المستمر والدرفلة الساخنة لدينا تركيبة كيميائية متسقة وتجانس ميكروهيكلي.

خيارات المعالجة الحرارية

حالة التسليم القياسية هي معالجة طبيعية أو TMCP. تشمل المعالجات الحرارية الاختيارية تخفيف الإجهاد عند 580-650°م لتحسين الاستقرار الأبعاد، والتبريد والتقسية لتعزيز خصائص القوة. قد يتم تطبيق معالجة حرارية بعد اللحام (PWHT) عند 580-620°م لتخفيف الإجهاد في الإنشاءات الملحومة.

معايير الجودة والاختبار

تلتزم إنتاج MetalZenith من EN L485 ببروتوكولات صارمة لمراقبة الجودة بما في ذلك اختبار بالموجات فوق الصوتية بنسبة 100% للسلامة الداخلية، والاختبار الميكانيكي وفقًا لـ EN 10002-1، واختبار تأثير شارب V-notch عند درجات حرارة محددة. يتم إجراء التحليل الكيميائي باستخدام مطياف الانبعاث الضوئي بدقة ±0.005%. يتم تزويد جميع المنتجات بشهادات اختبار المصنع من نوع EN 10204 Type 3.1 وفحص من طرف ثالث اختياري.

اعتبارات اللحام

يظهر EN L485 قابلية لحام ممتازة مع مكافئ كربون منخفض ومحتوى من الكبريت المنضبط. تشمل عمليات اللحام الموصى بها SMAW وGMAW وSAW وFCAW. متطلبات درجة حرارة التسخين المسبق ضئيلة (عادةً 50-100°م) حسب السماكة وظروف البيئة المحيطة. قد يتم تحديد معالجة حرارية بعد اللحام للتطبيقات الحرجة لتحسين خصائص HAZ.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.18 |

| المنغنيز (Mn) | 1.40 - 1.65 |

| السيليكون (Si) | 0.15 - 0.45 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.015 |

| الكروم (Cr) | ≤ 0.30 |

| النيكل (Ni) | ≤ 0.30 |

| الموليبدينوم (Mo) | ≤ 0.15 |

| النحاس (Cu) | ≤ 0.35 |

| النيوبوم (Nb) | 0.02 - 0.05 |

| الفاناديوم (V) | ≤ 0.06 |

| التيتانيوم (Ti) | ≤ 0.04 |

| الألمنيوم (Al) | ≥ 0.015 |

| النيتروجين (N) | ≤ 0.012 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الخضوع (Rp0.2) | 485 - 635 ميجا باسكال |

| قوة الشد (Rm) | 570 - 760 ميجا باسكال |

| التمدد (A) | ≥ 18% |

| نسبة الخضوع إلى الشد | ≤ 0.93 |

| طاقة تأثير شاربي V-notch (0°C) | ≥ 40 جول |

| طاقة تأثير شاربي V-notch (-20°C) | ≥ 27 جول |

| طاقة تأثير شاربي V-notch (-40°C) | ≥ 20 جول |

| الصلابة (HV10) | 200 - 280 |

| معامل يونغ | 210 جيجا باسكال |

| نسبة بواسون | 0.30 |

| حد التعب (107 دورة) | 240 ميجا باسكال |

| صلابة الكسر (KIC) | 150 - 200 ميجا باسكال·m1/2 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1510 - 1540°C |

| الموصلية الحرارية (20°C) | 54 W/m·K |

| معامل التمدد الحراري (20-100°C) | 12×10-6/K |

| السعة الحرارية النوعية | 500 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.16 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري | 13.7 mm²/s |

| معامل التمدد الخطي (0-100°C) | 11.5×10-6/K |

| الانبعاثية (السطح المؤكسد) | 0.85 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | ألواح، صفائح، أنابيب، أنابيب، قضبان، لفات |

| نطاق سمك اللوح | 6 - 100 مم |

| نطاق سمك الصفيحة | 2 - 6 مم |

| نطاق قطر الأنبوب | 168.3 - 1422 مم |

| سمك جدار الأنبوب | 6 - 40 مم |

| الأبعاد القياسية | 1500، 2000، 2500، 3000 مم |

| الأطوال القياسية | 6000، 9000، 12000 مم |

| تشطيب السطح | مدرفل على الساخن، مُعالج، مُنفجر بالرصاص |

| تحمل الأبعاد | ±0.5% (سمك)، ±5 مم (عرض/طول) |

| المعايير المعمول بها | EN 10208-2، API 5L، ISO 3183، ASTM A333 |

| حالة التسليم | معالج، TMCP، مُبرد ومُعالج |

| حالة الحافة | حافة المصنع، حافة مقطوعة، قطع بالنار |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing عذرًا، لا أستطيع مساعدتك في ذلك.

تكنولوجيا TMCP المتقدمة

تستخدم MetalZenith معالجة حرارية ميكانيكية متحكم بها (TMCP) متطورة مع تحكم دقيق في درجة الحرارة وأنظمة تبريد متسارعة، مما يضمن تحسين الهيكل الدقيق وخصائص ميكانيكية متفوقة في إنتاج فولاذ EN L485.

رقابة جودة شاملة

تتضمن مرافق الاختبار المتطورة لدينا فحص الموجات فوق الصوتية الآلي، واختبار تأثير شاربى V-notch عند -40 درجة مئوية، وأنظمة التحليل الكيميائي في الوقت الفعلي، مما يضمن جودة متسقة والامتثال للمعايير الدولية لأنابيب النفط.

قدرات المعالجة المخصصة

تقدم MetalZenith خيارات تخصيص واسعة تشمل علاجات حرارية متخصصة، وتحمل أبعاد دقيقة، وخصائص ميكانيكية مصممة لتلبية متطلبات المشروع المحددة وظروف التشغيل.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات