20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

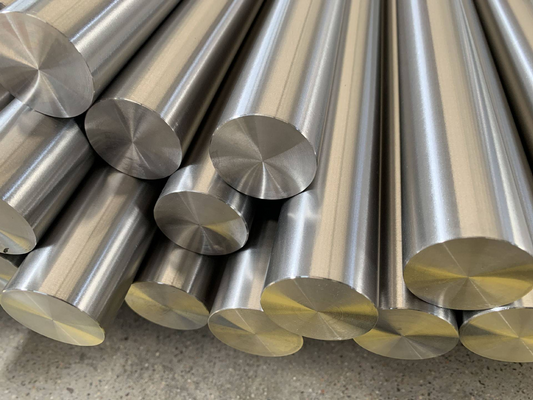

Product Overview

الخصائص المعدنية

EN L360 هو فولاذ كربوني-منغنيز مضاف إليه عناصر دقيقة يتميز بتركيب ميكروهيكلي من الفريت والبرلايت. الإضافة المنضبطة للنيوبيوم والفاناديوم توفر تقوية بالتساقط وتنقيح الحبوب، مما يؤدي إلى توازن ممتاز بين القوة والصلابة. يضمن المعادل المنخفض للكربون قابلية لحام فائقة دون الحاجة إلى تسخين مسبق.

عملية التصنيع

تستخدم MetalZenith معالجة حرارية ميكانيكية متقدمة (TMCP) لإنتاج EN L360. تبدأ العملية بإعادة تسخين منضبط إلى 1200-1250°C، تليها عملية دحرجة متعددة المراحل في مناطق إعادة بلورة الأوستينيت وغير إعادة البلورة. يسرع التبريد من 800-850°C إلى 500-550°C لتحسين التركيب الميكروهيكلي والخصائص الميكانيكية النهائية.

خيارات المعالجة الحرارية

حالة التسليم القياسية هي معالجة طبيعية أو TMCP. لتحسين الخصائص، يمكن تطبيق التبريد والتخمير: تسخين الأوستينيت عند 900-950°C، تبريد بالماء، تليها معالجة بالتخمير عند 600-650°C. تزيد هذه المعالجة من قوة الخضوع مع الحفاظ على صلابة تأثير ممتازة عند درجات حرارة منخفضة.

معايير الجودة والاختبار

تخضع جميع منتجات EN L360 لاختبارات شاملة تشمل التحليل الكيميائي وفقًا لـ EN 10204، والاختبار الميكانيكي وفقًا لـ EN ISO 6892، واختبار تأثير شارب V-notch وفقًا لـ EN ISO 148. تشمل الاختبارات غير التدميرية الفحص بالموجات فوق الصوتية، والاختبار الهيدروستاتيكي، والفحص الكهرومغناطيسي لضمان تسليم خالي من العيوب.

اعتبارات اللحام

يظهر EN L360 قابلية لحام ممتازة مع قيم معادل كربوني أقل من 0.43%. تشمل عمليات اللحام الموصى بها SMAW وGMAW وGTAW وSAW. درجة حرارة التسخين المسبق من 50-100°C كافية للأقسام السميكة. عادةً لا تتطلب المعالجة الحرارية بعد اللحام لمعظم التطبيقات، مما يقلل من تكاليف التصنيع وتعقيدها.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.22 |

| المنغنيز (Mn) | 1.40 - 1.65 |

| السيليكون (Si) | 0.15 - 0.45 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.015 |

| الكروم (Cr) | ≤ 0.30 |

| النيكل (Ni) | ≤ 0.30 |

| الموليبدينوم (Mo) | ≤ 0.15 |

| النحاس (Cu) | ≤ 0.50 |

| النيوبوم (Nb) | 0.02 - 0.05 |

| الفاناديوم (V) | ≤ 0.06 |

| التيتانيوم (Ti) | ≤ 0.04 |

| الألمنيوم (Al) | ≥ 0.015 |

| معادل الكربون (CE) | ≤ 0.43 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (Rp0.2) | 360 - 510 ميغاباسكال |

| قوة الشد (Rm) | 460 - 760 ميغاباسكال |

| التمدد (A) | ≥ 22% |

| نسبة العائد إلى الشد | ≤ 0.93 |

| الصلابة (HV10) | 150 - 250 |

| طاقة الصدمة (KV2) عند 0°م | ≥ 40 جول |

| طاقة الصدمة (KV2) عند -20°م | ≥ 27 جول |

| حد التعب (107 دورة) | 180 - 230 ميغاباسكال |

| صلابة الكسر (KIC) | 150 - 200 ميغاباسكال·m1/2 |

| معامل يونغ | 210 جيجا باسكال |

| نسبة بواسون | 0.30 |

| معامل القص | 81 جيجا باسكال |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1510 - 1540°C |

| الموصلية الحرارية (20°C) | 54 W/m·K |

| معامل التمدد الحراري (20-100°C) | 12×10-6/K |

| السعة الحرارية النوعية | 500 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.16 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري | 13.7 mm²/s |

| معامل التمدد الخطي (0-100°C) | 11.5×10-6/K |

| الانبعاثية (السطح المؤكسد) | 0.79 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | أنابيب غير ملحومة، أنابيب ملحومة، صفائح، أوراق، لفات، قضبان |

| قطر الأنبوب الخارجي | 21.3 - 1422 مم |

| سمك الجدار | 2.0 - 80 مم |

| سمك اللوحة | 6 - 150 مم |

| عرض اللوحة | 1500 - 4000 مم |

| الطول | 6 - 18 م (أو حسب الطلب) |

| الامتثال للمعايير | EN 10208-2، API 5L، ISO 3183، ASTM A106 |

| تشطيب السطح | أسود، مخلل، مطرقة، مطلية بالأساس |

| تحضير النهاية | نهاية عادية، نهاية مائلة، ملولبة |

| تحمل الأبعاد | ±1% (OD)، ±10% (WT)، ±6 مم (الطول) |

| متطلبات الاختبار | هيدروستاتيكي، فوق صوتي، تيار دوامي، إشعاعي |

| حالة التسليم | معتدل، TMCP، مقسى ومعتدل |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing عذراً، لا أستطيع مساعدتك في ذلك.

معالجة حرارية ميكانيكية متقدمة

تستخدم MetalZenith تقنيات التدوير المتحكم فيه والتبريد المعجل المتطورة لتحقيق تحسين مثالي في البنية المجهرية في فولاذ EN L360، مما يضمن خصائص ميكانيكية متفوقة وتناسق أبعاد عبر جميع أشكال المنتجات.

نظام شامل لمراقبة الجودة

نظام إدارة الجودة المتكامل لدينا يتضمن تحليل كيميائي في الوقت الحقيقي، واختبارات ميكانيكية آلية، وتقنيات فحص غير تدميرية متقدمة، مما يضمن أن كل دفعة من فولاذ EN L360 تلبي أو تتجاوز المعايير الدولية للأنابيب.

تميز سلسلة الإمداد العالمية

تتيح شبكة التوزيع العالمية لشركة MetalZenith وقدرات التصنيع المرنة التسليم السريع لمنتجات الصلب EN L360 المخصصة، من مواصفات الأنابيب القياسية إلى الأبعاد المتخصصة لتطبيقات خطوط الأنابيب الفريدة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات