20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

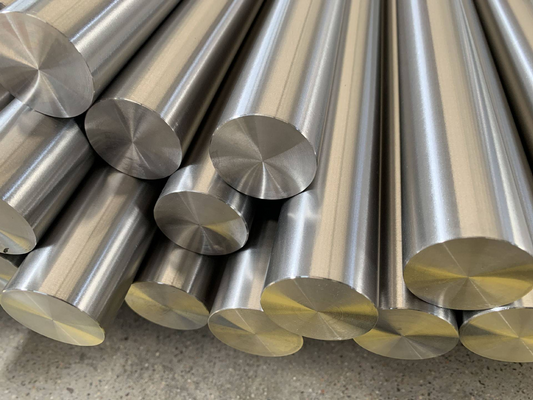

Product Overview

الخصائص المعدنية

EN L245 هو فولاذ منخفض الكربون مع هيكل دقيق يتكون بشكل أساسي من الفريت والبيرلايت. الإضافة المنضبطة لعناصر الميكروسبائك مثل الفاناديوم والنيوبيوم توفر تحسين الحبوب وتقوية الترسيب، مما يؤدي إلى تحسين توازن القوة والصلابة.

عملية التصنيع

تنتج MetalZenith فولاذ EN L245 من خلال عمليات تصنيع فولاذ متقدمة تشمل صهر فرن القوس الكهربائي، وتنقية القادوس، والصب المستمر. يخضع الفولاذ للدرفلة المنضبطة في منطقة الأوستنيت تليها تبريد متسارع لتحقيق الخصائص الميكانيكية والهيكل الدقيق المطلوب.

معالجة الحرارة

عادة ما يتم توفير فولاذ EN L245 في حالة معالجة حرارية أو معالجة حرارية ميكانيكية. يتم إجراء التطبيع عند 900-950°C تليها تبريد في الهواء. للحصول على خصائص محسنة، قد يتم استخدام الدرفلة المنضبطة مع درجات حرارة الدرفلة النهائية من 750-850°C.

خصائص اللحام

يضمن المعادل المنخفض للكربون (CE ≤ 0.43%) قابلية لحام ممتازة دون الحاجة إلى التسخين المسبق لمعظم التطبيقات. تشمل عمليات اللحام الشائعة SMAW و GMAW و GTAW و SAW. عادةً لا تتطلب معالجة الحرارة بعد اللحام للسمك حتى 25 مم.

معايير الجودة

يتوافق فولاذ EN L245 من MetalZenith مع EN 10208-1 لأنابيب الفولاذ لأغراض الضغط، وAPI 5L لأنابيب الخط، وISO 3183 لصناعات النفط والغاز الطبيعي. تخضع جميع المنتجات لاختبارات صارمة تشمل التحليل الكيميائي، واختبار الشد، واختبار الصدمات، واختبار الصلابة، والفحص غير المدمر.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.21 |

| المنغنيز (Mn) | ≤ 1.20 |

| السيليكون (Si) | ≤ 0.40 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.015 |

| الكروم (Cr) | ≤ 0.30 |

| النيكل (Ni) | ≤ 0.30 |

| الموليبدينوم (Mo) | ≤ 0.15 |

| النحاس (Cu) | ≤ 0.50 |

| الفاناديوم (V) | ≤ 0.06 |

| النيوبيم (Nb) | ≤ 0.05 |

| التيتانيوم (Ti) | ≤ 0.04 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة العائد (Rt0.5) | 245-450 ميجا باسكال |

| قوة الشد (Rm) | 415-565 ميجا باسكال |

| التمدد (A) | ≥ 22% |

| نسبة العائد إلى الشد | ≤ 0.93 |

| طاقة تأثير شاربي V-Notch (0°C) | ≥ 27 جول |

| الصلابة (HV10) | ≤ 250 |

| معامل يونغ | 210 جيجا باسكال |

| نسبة بواسون | 0.30 |

| حد التعب (10^7 دورات) | 180 ميجا باسكال |

| صلابة الكسر (KIC) | 120-150 ميجا باسكال·m^0.5 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1510°C |

| الموصلية الحرارية (20°C) | 54 W/m·K |

| معامل التمدد الحراري (20-100°C) | 12×10-6/K |

| السعة الحرارية النوعية | 500 J/kg·K |

| المقاومة الكهربائية (20°C) | 0.16 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري | 13.7 mm²/s |

| الانبعاثية (السطح المؤكسد) | 0.85 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | أنابيب غير ملحومة، أنابيب ملحومة، ألواح، صفائح، لفات |

| نطاق قطر الأنبوب | 21.3mm - 1422mm (NPS 1/2 - 56) |

| سمك الجدار | 2.0mm - 80mm |

| سمك اللوحة | 6mm - 100mm |

| نطاق الطول | 5.8m - 18m (طول عشوائي/ثابت) |

| الامتثال للمعايير | EN 10208-1، API 5L، ISO 3183، ASTM A53 |

| تشطيب السطح | أسود، مجلفن، مطلي بـ 3PE، مطلي بـ FBE |

| تحضير النهاية | نهاية عادية، نهاية مائلة، ملولبة |

| تحمل الأبعاد | ±1% (القطر)، ±12.5% (سمك الجدار) |

| متطلبات الاختبار | اختبار هيدروستاتيكي، NDT، تحليل كيميائي، اختبار ميكانيكي |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing عذرًا، لا أستطيع مساعدتك في ذلك.

معالجة حرارية ميكانيكية متقدمة

تستخدم MetalZenith تقنية الدرفلة المتحكم بها والتبريد المعجل لتحقيق تحسين مثالي للحبيبات وتعزيز الخصائص الميكانيكية في فولاذ EN L245، مما يضمن متانة فائقة وميكروهيكل موحد في جميع أنحاء المادة.

نظام شامل لمراقبة الجودة

يتم إجراء فحص بالموجات فوق الصوتية بنسبة 100% ، وتحليل كيميائي ، واختبار ميكانيكي على كل دفعة في مختبر الاختبار المتطور لدينا. تضمن المعدات المتقدمة لفحص NDT وعلماء المعادن المعتمدين أن الفولاذ EN L245 يلبي أعلى معايير خطوط الأنابيب الدولية.

معالجة مخصصة والإمداد العالمي

تقدم MetalZenith حلول معالجة مخصصة تشمل الأبعاد المخصصة، ومعالجات السطح، ومعالجات الحرارة المتخصصة. تضمن شبكتنا اللوجستية العالمية التسليم في الوقت المناسب لمنتجات الصلب EN L245 في جميع أنحاء العالم مع الوثائق والشهادات الكاملة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات