20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

Product Overview

الخصائص المعدنية

يظهر فولاذ الأدوات D3 بنية مجهرية معقدة تتكون من مصفوفة مارتينسيتية مع كربيدات الكروم الموزعة بشكل موحد (M7C3 و M23C6). يوفر محتوى الكربون العالي (2.0-2.35%) مع إضافة الكروم الكبيرة (11-13%) مقاومة استثنائية للتآكل من خلال تشكيل كربيدات صلبة. تلغي خصائص التصلب بالهواء الحاجة إلى التبريد بالزيت، مما يقلل من مخاطر التشوه والتصدع في هندسة الأدوات المعقدة.

عملية المعالجة الحرارية

تستخدم MetalZenith التصلب في جو محكم عند 980-1020 درجة مئوية يتبعه تبريد بالهواء لتحقيق صلابة مثالية. يتم تطبيق معالجة تحت الصفر عند -80 درجة مئوية لتقليل محتوى الأوستينيت المحتجز إلى أقل من 5%. يضمن التخمير المزدوج عند 150-200 درجة مئوية استقرار الأبعاد وتخفيف الإجهاد مع الحفاظ على مستويات صلابة تتراوح بين 58-62 HRC لأقصى أداء للأدوات.

عملية التصنيع المتقدمة

تبدأ عملية الإنتاج لدينا بالذوبان بالتحريض في الفراغ لضمان تجانس كيميائي وتقليل الشوائب. يعمل إعادة الذوبان بالكهرباء على تحسين البنية المجهرية وإزالة التوزيع غير المتجانس. يضمن التشكيل المحكم مع مراقبة دقيقة لدرجة الحرارة تحسين تدفق الحبوب وتوزيع الكربيدات. تحافظ عمليات التشغيل النهائية والطحن على ت tolerances الأبعاد الضيقة الضرورية لتطبيقات الأدوات الدقيقة.

اختبارات الجودة المتخصصة

تقوم MetalZenith بتنفيذ بروتوكولات اختبار شاملة تشمل رسم توزيع صلابة روكويل عبر المقطع العرضي بالكامل، وتحليل حيود الأشعة السينية لتحديد كمية الأوستينيت المحتجز (الهدف <5%)، وفحص معدني لحجم الكربيدات وتوزيعها المتجانس، واختبار إجهاد الشعاع الدوار عند 10^7 دورة. يضمن اختبار استقرار الأبعاد تحت ظروف الدورة الحرارية أداءً متوقعًا في التطبيقات الدقيقة.

اعتبارات تقنية محددة للتطبيق

بالنسبة لتطبيقات أدوات القطع، فإن مقاومة التآكل العالية والاحتفاظ بالحافة لـ D3 تجعلها مثالية لعمليات التقطيع والتشكيل على المواد الصلبة. في تصنيع القوالب، تقلل خصائص التصلب بالهواء من التشوه في الهندسات المعقدة. بالنسبة لتطبيقات المحامل، يوفر التوزيع المتجانس للكربيدات أنماط تآكل متسقة وعمر خدمة ممتد. في الآلات الدقيقة، يضمن استقرار الأبعاد بعد المعالجة الحرارية tolerances الضيقة. بالنسبة لمكونات السيارات، يوفر الجمع بين الصلابة والصلابة أداءً موثوقًا تحت ظروف التحميل الدوري.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 2.00 - 2.35 |

| الكروم (Cr) | 11.00 - 13.00 |

| المنغنيز (Mn) | 0.15 - 0.45 |

| السيليكون (Si) | 0.10 - 0.60 |

| الفوسفور (P) | ≤ 0.030 |

| الكبريت (S) | ≤ 0.030 |

| الفاناديوم (V) | ≤ 1.00 |

| الموليبدينوم (Mo) | ≤ 1.00 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| الصلابة (HRC) | 58 - 62 |

| قوة الضغط (MPa) | ≥ 2800 |

| صلابة الصدمة (J) | 15 - 25 |

| مؤشر مقاومة التآكل | 8.5 - 9.2 |

| قابلية الصلابة (mm) | 75 - 100 |

| قوة التعب (MPa) | ≥ 850 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/سم³) | 7.70 |

| نقطة الانصهار (°م) | 1420 - 1460 |

| الموصلية الحرارية (W/m·K) | 20.5 |

| التمدد الحراري (×10??/K) | 10.8 |

| معامل المرونة (جيجا باسكال) | 210 |

| نسبة بواسون | 0.27 - 0.30 |

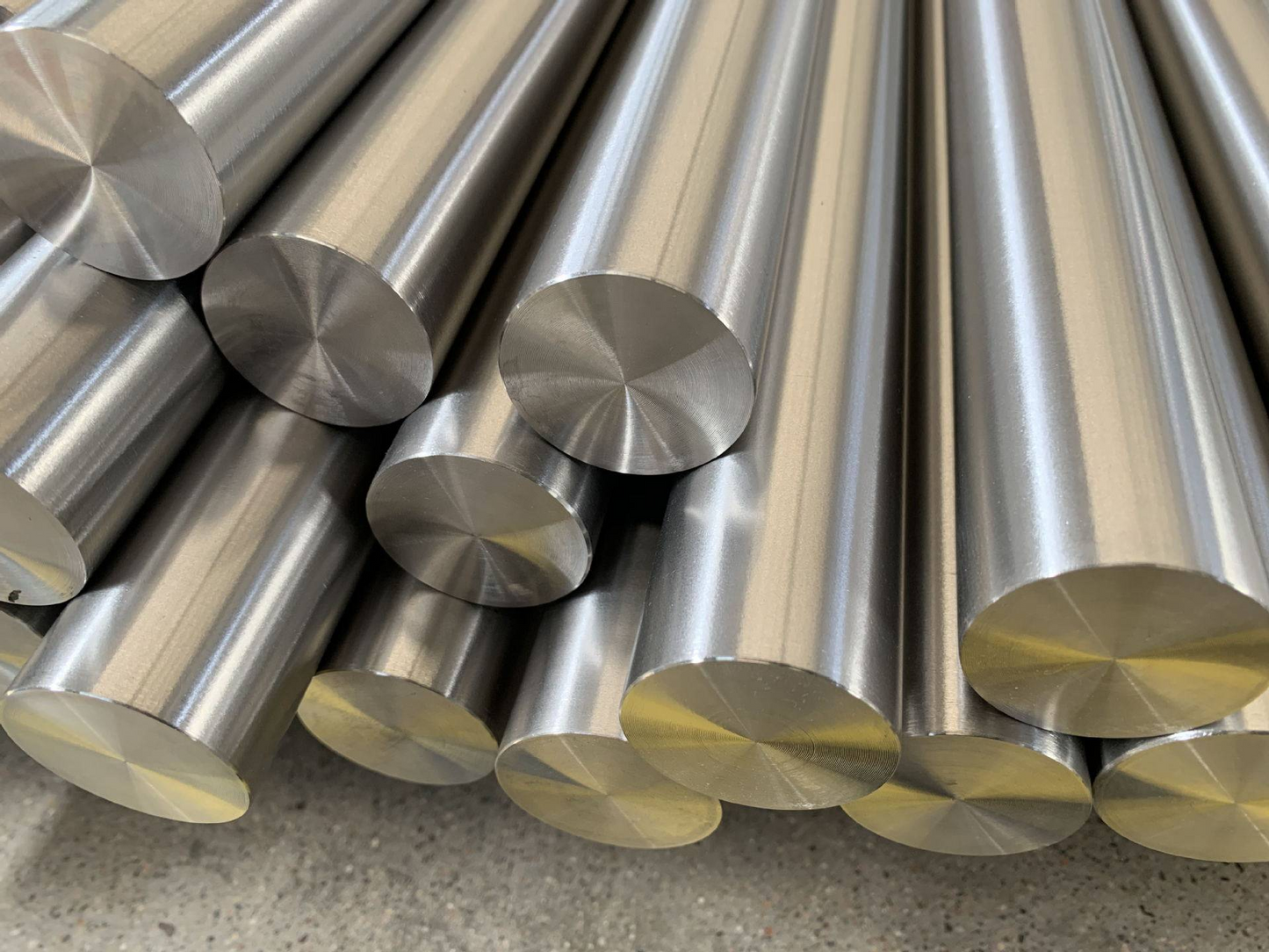

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | دوائر، مسطحات، مربعات، ألواح، تشكيلات مخصصة |

| نطاق القطر | 10 - 500 مم |

| نطاق السماكة | 5 - 200 مم |

| نطاق الطول | 100 - 6000 مم |

| الامتثال للمعايير | ASTM A681، DIN 1.2080، JIS SKD1 |

| حالة المعالجة الحرارية | مخمرة، مقواة ومعتدلة |

| تشطيب السطح | مدرفلة على الساخن، مسحوبة على البارد، مصقولة بدقة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing فولاذ أداة D3

تكنولوجيا الصهر بالفراغ المتقدمة

MetalZenith تستخدم تقنية الصهر بالتحريض الفراغي المتطورة تليها إعادة الصهر بالكهرباء لتحقيق نظافة فائقة وتوزيع متجانس للكربيد. تضمن عملية التشكيل الخاضعة للرقابة مع مراقبة دقيقة لدرجة الحرارة تدفق حبيبات مثالي وتلغي الفصل، مما يؤدي إلى خصائص ميكانيكية متسقة في جميع أنحاء مقطع المادة.

اختبار الفولاذ الأدوات الشامل

تشمل بروتوكولات الاختبار المتخصصة لدينا رسم صلابة روكويل عبر المقطع العرضي بالكامل، وتحليل حيود الأشعة السينية لقياس محتوى الأوستينيت المتبقي، وفحص المعادن لدراسة توزيع الكربيد، واختبار التعب باستخدام شعاع دوار. تضمن هذه التدابير المتقدمة لمراقبة الجودة الأداء الأمثل في تطبيقات الأدوات المت demanding.

خدمات المعالجة الحرارية المخصصة

تقدم MetalZenith حلول معالجة حرارية مخصصة تشمل تصلب الفراغ، المعالجة تحت الصفر، والتخمير الدقيق باستخدام أفران جوية تتحكم فيها الكمبيوتر. يوفر مهندسونا المعدنيون الدعم الفني لمتطلبات الصلابة المحددة للتطبيقات وتحسين الاستقرار الأبعاد، مما يضمن أقصى عمر وأداء للأدوات.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات