20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

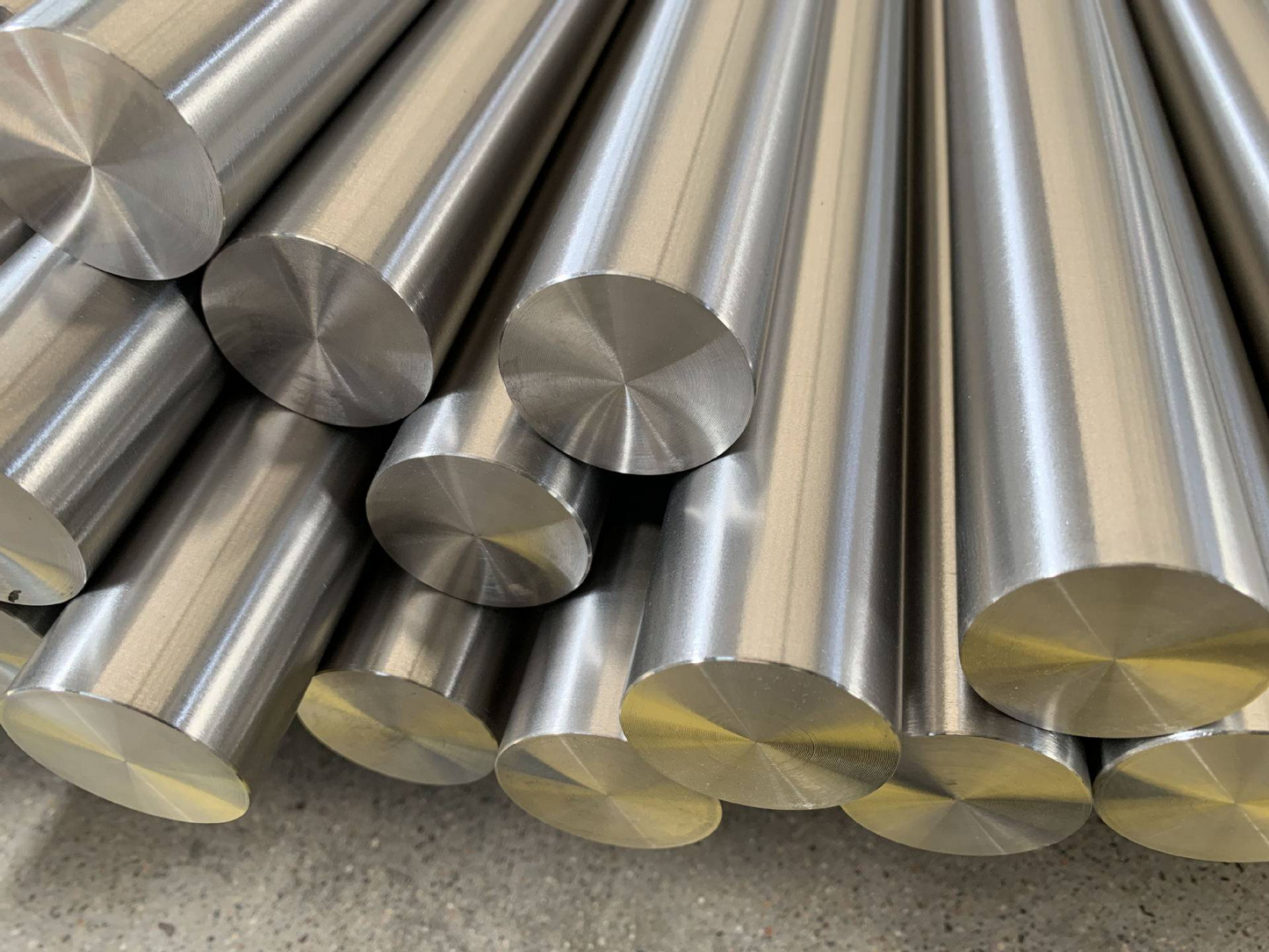

Product Overview

الخصائص المعدنية

AISI H21 هو فولاذ أدوات العمل الساخن من نوع التنجستن يتميز بمحتواه العالي من التنجستن (8.5-10.0%) الذي يوفر قوة استثنائية عند درجات الحرارة العالية ومقاومة للصدمات الحرارية. يتكون الميكروهيكل للفولاذ من مصفوفة مارتنزيتية معززة مع كربيدات التنجستن والفاناديوم الموزعة بشكل موحد. تحافظ هذه الكربيدات على صلابتها ومقاومتها للتآكل عند درجات الحرارة المرتفعة، مما يجعل H21 مثاليًا لتطبيقات العمل الساخن. يعزز محتوى الكروم (3.0-3.75%) من القدرة على التصلب ويوفر مقاومة معتدلة للتآكل.

عملية المعالجة الحرارية

تستخدم MetalZenith دورات معالجة حرارية دقيقة التحكم تم تحسينها لـ AISI H21. يتم إجراء التلدين عند 870-900°C يتبعه تبريد بطيء لتحقيق أقصى قابلية للتشغيل. تتضمن عملية التصلب تسخينًا مسبقًا إلى 650-700°C، ثم التسخين إلى 1000-1030°C في جو محمي، يتبعه تبريد بالهواء أو تلطيف بالزيت حسب حجم القسم. يتم إجراء التلدين عند 540-650°C لتحقيق الصلابة المطلوبة للعمل والتي تتراوح بين 42-48 HRC. يُوصى بالتلدين المزدوج لضمان الاستقرار الأبعاد وتخفيف الضغط.

تميز عملية التصنيع

تبدأ عملية التصنيع لدينا بالذوبان بالتحريض الفراغي (VIM) باستخدام مواد خام عالية النقاء، يتبعها إعادة الذوبان بالتيار الكهربائي (ESR) للقضاء على الشوائب وتحقيق نظافة استثنائية. تخضع القضبان لعمليات تشكيل ودرفلة محكومة لتنقيح هيكل الحبيبات وضمان توزيع موحد للكربيدات. يتم العمل الساخن ضمن نطاق درجات الحرارة من 1150-850°C مع التحكم الدقيق في معدلات التشوه لمنع التشقق. تخضع جميع المنتجات لاختبارات فوق صوتية شاملة، وتحليل كيميائي، والتحقق من الخصائص الميكانيكية.

معايير الجودة والشهادات

تحافظ MetalZenith على شهادة ISO 9001:2015 وتلتزم بالمعايير الدولية بما في ذلك ASTM A681 وEN ISO 4957 وJIS SKD61. مختبر مراقبة الجودة لدينا مجهز بمعدات اختبار متقدمة بما في ذلك مطياف الانبعاث الضوئي، وآلات الاختبار العالمية، ومقاييس الصلابة، وأنظمة تحليل المعادن. تخضع كل دفعة لاختبارات صارمة تشمل التحقق من التركيب الكيميائي، واختبار الخصائص الميكانيكية، وفحص الميكروهيكل، والتفتيش الأبعاد. يتم توفير تتبع كامل للمواد ووثائق الشهادات مع كل شحنة.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.28 - 0.35 |

| المنغنيز (Mn) | 0.15 - 0.40 |

| السيليكون (Si) | 0.15 - 0.40 |

| الفوسفور (P) | ≤ 0.030 |

| الكبريت (S) | ≤ 0.030 |

| الكروم (Cr) | 3.00 - 3.75 |

| التنجستن (W) | 8.50 - 10.00 |

| الفاناديوم (V) | 0.30 - 0.60 |

| النيكل (Ni) | ≤ 0.30 |

| الموليبدينوم (Mo) | ≤ 0.30 |

| النحاس (Cu) | ≤ 0.25 |

⚙️ Mechanical Properties

| الخاصية | القيمة | الحالة |

|---|---|---|

| قوة الشد | 1380 - 1520 ميجا باسكال | مُعالج ومُقسى |

| قوة العائد (0.2% انحراف) | 1240 - 1380 ميجا باسكال | مُعالج ومُقسى |

| التمدد | 8 - 12% | مُعالج ومُقسى |

| تقليل المساحة | 25 - 35% | مُعالج ومُقسى |

| الصلابة (HRC) | 42 - 48 | صلابة العمل |

| الصلابة (HRC) | 52 - 58 | أقصى صلابة |

| طاقة الصدمة (Charpy V-notch) | 15 - 25 جول | درجة حرارة الغرفة |

| حد التعب | 620 - 690 ميجا باسكال | 10&sup7; دورة |

| معامل المرونة | 210 - 220 جيجا باسكال | درجة حرارة الغرفة |

| نسبة بواسون | 0.27 - 0.30 | درجة حرارة الغرفة |

🔬 Physical Properties

| الخاصية | القيمة | درجة الحرارة |

|---|---|---|

| الكثافة | 8.15 جرام/سم³ | 20°م |

| نقطة الانصهار | 1480 - 1520°م | - |

| الموصلية الحرارية | 24.5 واط/م·ك | 20°م |

| الموصلية الحرارية | 28.8 واط/م·ك | 400°م |

| معامل التمدد الحراري | 11.2×10-6/ك | 20-100°م |

| معامل التمدد الحراري | 12.8×10-6/ك | 20-400°م |

| السعة الحرارية النوعية | 460 جول/كغ·ك | 20°م |

| المقاومة الكهربائية | 0.65 µΩ·م | 20°م |

| نفاذية مغناطيسية | مغناطيسي حديدي | درجة حرارة الغرفة |

| الانتشار الحراري | 6.5×10-6 م²/ث | 20°م |

📏 Product Specifications

| المواصفات | الخيارات المتاحة | المعايير |

|---|---|---|

| أشكال المنتج | قضبان دائرية، قضبان مسطحة، ألواح، كتل، طرق | ASTM A681 |

| قطر القضيب الدائري | 10 - 500 مم | ASTM A681 |

| سمك القضيب المسطح | 8 - 150 مم | ASTM A681 |

| سمك اللوحة | 20 - 300 مم | ASTM A681 |

| أبعاد الكتلة | حتى 1000×500×300 مم | مخصص |

| تشطيب السطح | مدرفل ساخن، مخلل، مشغول، مصقول | ASTM A681 |

| تحمل الأبعاد | ±0.5 مم (قياسي)، ±0.1 مم (دقيق) | ISO 2768 |

| الطول | حتى 6000 مم (قياسي)، أطول متاح | مخصص |

| حالة المعالجة الحرارية | مخلل، مُعادل، مُقسى ومُعالج | ASTM A681 |

| معايير الجودة | ISO 9001:2015، ASTM A681، EN ISO 4957 | دولي |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing AISI H21

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith عمليات الصهر بالتحريض الفراغي (VIM) وإعادة الصهر بالتيار الكهربائي (ESR) لإنتاج AISI H21 مع نظافة استثنائية وتجانس. تضمن عملية الصهر في جو محكم التحكم القضاء على الشوائب وتوزيع الكربيد بشكل مثالي، مما يؤدي إلى خصائص ميكانيكية متفوقة وأداء عمر أداة ممتد.

تحكم دقيق في معالجة الحرارة

تتميز مرافق المعالجة الحرارية المتطورة لدينا بأفران تتحكم فيها الكمبيوتر مع دقة في توحيد درجة الحرارة والتحكم في الأجواء. نحن نطبق دورات معالجة حرارية ملكية تم تحسينها لـ AISI H21، مما يضمن ملفات صلابة متسقة، واستقرار أبعاد، وأقصى مقاومة للصدمات الحرارية عبر جميع أشكال المنتجات.

تخصيص كامل ودعم فني

تقدم MetalZenith خدمات تخصيص شاملة تشمل التشغيل الدقيق، ومعالجات السطح، ومعالجة الحرارة الخاصة بالتطبيقات. يوفر فريقنا الهندسي المعدني استشارات فنية، وتحليل الفشل، وخدمات تحسين الأدوات، مدعومة بسلسلة التوريد العالمية لدينا وقدرات التسليم السريع.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات