20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

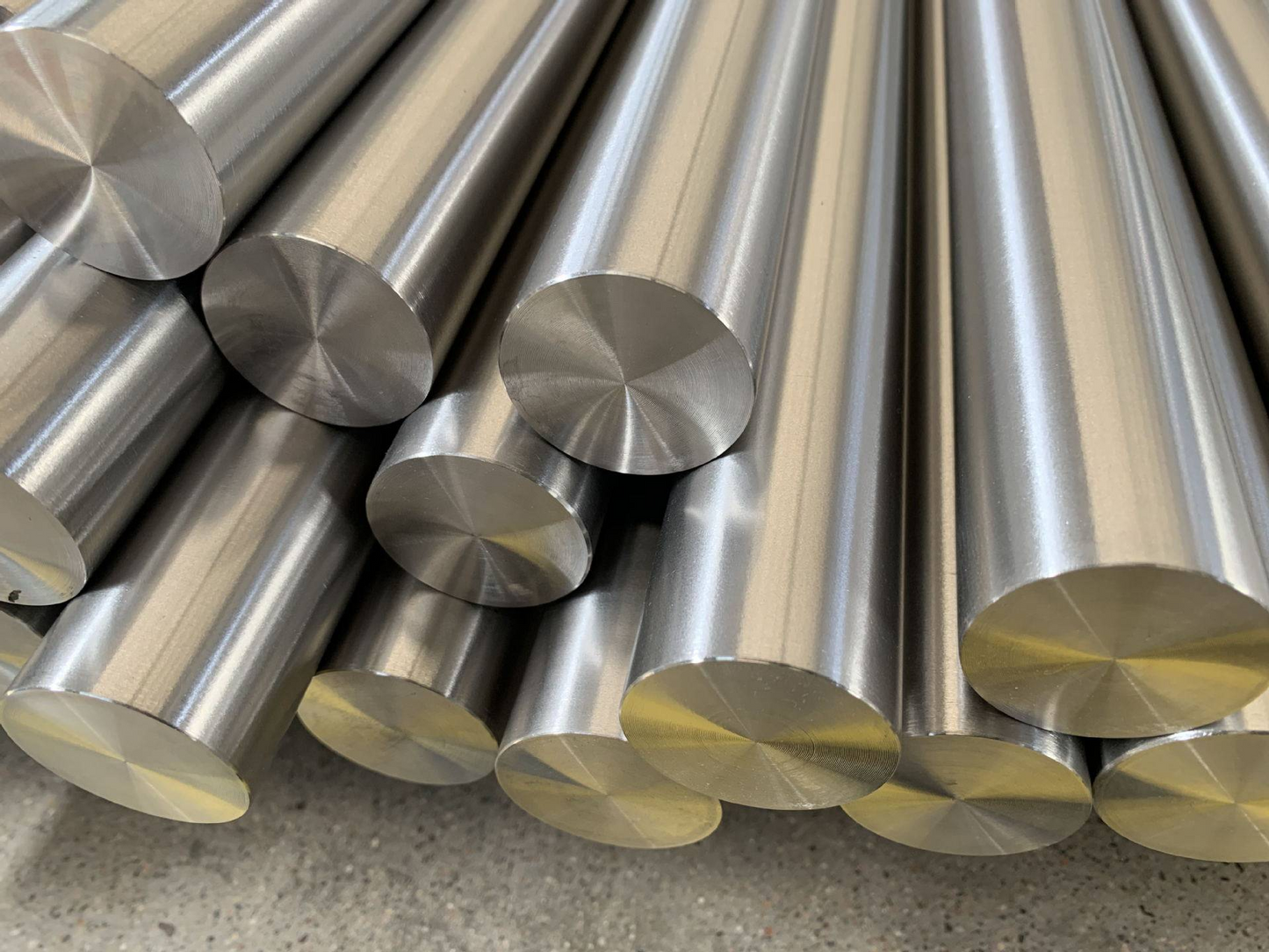

Product Overview

الخصائص المعدنية

فولاذ A2 يظهر بنية ميكروية مارتنسيتية مع كربيدات الكروم والموليبدينوم الموزعة بشكل موحد بعد المعالجة الحرارية المناسبة. توفر مورفولوجيا الكربيد المتحكم بها مقاومة ممتازة للتآكل مع الحفاظ على متانة كافية. خاصية التصلب في الهواء تقضي على مخاطر التشقق الناتجة عن التبريد السريع وتضمن الاستقرار الأبعاد أثناء المعالجة الحرارية.

عملية المعالجة الحرارية

تستخدم MetalZenith تصلب الغلاف الجوي المتحكم به عند 925-980 درجة مئوية تليها تبريد في الهواء لتحقيق صلابة مثالية. يسمح التخمير عند 150-540 درجة مئوية بتعديل دقيق للصلابة مع الحفاظ على الاستقرار الأبعاد. تضمن قدرات المعالجة الحرارية في الفراغ لدينا نتائج متسقة وجودة سطحية متفوقة.

عملية التصنيع

تستخدم إنتاج A2 لدينا صهر التحريض في الفراغ تليه إعادة صهر الكهروسلغ لتنظيف استثنائي. يضمن التشكيل المتحكم به مع مراقبة دقيقة لدرجة الحرارة توزيع كربيد مثالي وتنقية الحبوب. توفر قدرات التشغيل المتقدمة ت tolerances ضيقة وتشطيبات سطحية متفوقة لتطبيقات الأدوات المت demanding.

اختبارات الجودة المتخصصة

تقوم MetalZenith بإجراء رسم خرائط شامل لتوزيع صلابة روكويل عبر مقاطع الأدوات، وتحليل حيود الأشعة السينية للتحقق من محتوى الأوستينيت المتبقي، وفحص معدني مفصل لحجم الكربيد وتوزيعه، واختبار إجهاد الشعاع الدوار للتحقق من توقعات عمر الأداة في ظروف الخدمة.

اعتبارات محددة للتطبيقات

لتطبيقات أدوات القطع، يوفر A2 لدينا احتفاظًا ممتازًا بالحواف واستقرارًا أبعادياً. في تصنيع القوالب، تمنع المتانة المتفوقة الفشل المبكر مع الحفاظ على مقاومة التآكل. لتطبيقات المحامل، تضمن بنية الكربيد الدقيقة تشغيلًا سلسًا وعمر خدمة ممتد. تستفيد مكونات الآلات الدقيقة من قابلية التشغيل الممتازة والاستقرار الأبعاد، بينما تستفيد تطبيقات أدوات السيارات من الصلابة المتسقة ومقاومة التعب.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | 0.95 - 1.05 |

| الكروم (Cr) | 4.75 - 5.50 |

| الموليبدينوم (Mo) | 0.90 - 1.40 |

| الفاناديوم (V) | 0.15 - 0.50 |

| المنغنيز (Mn) | 0.40 - 1.00 |

| السيليكون (Si) | 0.10 - 0.60 |

| الفوسفور (P) | ≤ 0.025 |

| الكبريت (S) | ≤ 0.025 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| الصلابة (HRC) | 57 - 62 |

| قوة الضغط (MPa) | 2800 - 3200 |

| صلابة الصدمة (J) | 15 - 25 |

| مؤشر مقاومة التآكل | 8.5 - 9.2 |

| قابلية الصلابة (mm) | 75 - 100 |

| قوة التعب (MPa) | 850 - 950 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة (غ/سم³) | 7.86 |

| نقطة الانصهار (°م) | 1480 - 1520 |

| التوصيل الحراري (W/m·K) | 24.3 |

| التمدد الحراري (×10??/K) | 11.9 |

| معامل المرونة (GPa) | 210 |

| نسبة بواسون | 0.27 - 0.30 |

📏 Product Specifications

| المواصفات | التفاصيل |

|---|---|

| الأشكال المتاحة | أشرطة، ألواح، كتل، مخزون دقيق المعالجة |

| نطاق القطر | 6 - 300 مم |

| نطاق السماكة | 3 - 200 مم |

| نطاق الطول | 100 - 6000 مم |

| الامتثال للمعايير | ASTM A681، AISI A2، DIN 1.2363 |

| حالة المعالجة الحرارية | مخمرة، مقواة ومعتدلة |

| تشطيب السطح | مدرفلة على الساخن، مسحوبة على البارد، معالجة دقيقة |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing فولاذ أداة A2

تكنولوجيا الصهر بالفراغ المتقدمة

تستخدم MetalZenith صهر التحريض الفراغي يليه صهر electroslag لتحقيق نظافة استثنائية وتجانس في فولاذ الأدوات A2. تضمن عملية التشكيل التي نتحكم فيها مع مراقبة دقيقة لدرجة الحرارة توزيع الكربيد الأمثل وتنقيح بنية الحبوب لأداء أدوات متفوق.

بروتوكول اختبار الجودة الشامل

تشمل اختباراتنا المتخصصة رسم خرائط توزيع صلابة روكويل، وتحليل محتوى الأوستينيت المتبقي عبر حيود الأشعة السينية، وتقييم توزيع الكاربيد من خلال التحليل المعدني، واختبار إجهاد الشعاع الدوار لضمان أداء متسق في تطبيقات الأدوات المت demanding.

خدمات المعالجة الحرارية المخصصة

تقدم MetalZenith حلول معالجة حرارية مخصصة تشمل تقسية الغلاف الجوي المتحكم فيه، والتلطيف الدقيق، وخدمات تخفيف الإجهاد. يوفر فريقنا الفني دعمًا شاملاً لتحسين تصميم الأدوات وتعزيز الأداء بناءً على متطلبات التطبيق المحددة.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات