20 Anos de Experiência | 1000+ Parceiros de Marca | Personalização Completa

Temos 20 anos de experiência na indústria, fizemos parceria com mais de 1.000 marcas e apoiamos quaisquer necessidades de personalização.

Technical Specifications

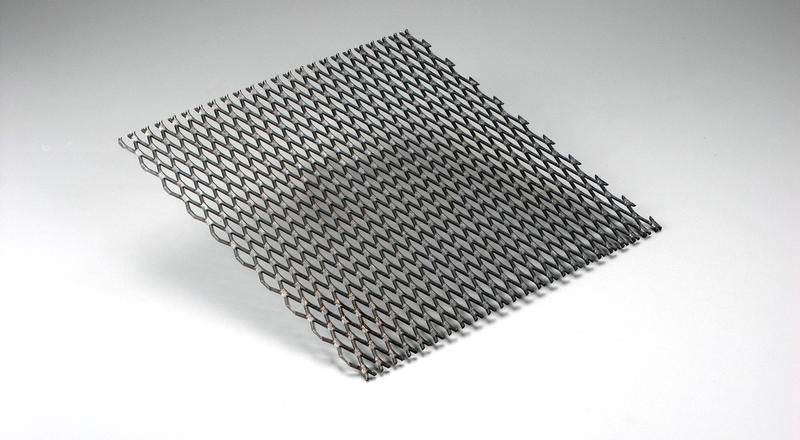

Product Overview

Metal Expandido de Aço Elevado é fabricado a partir de aço carbono de alta qualidade através de um processo de expansão de precisão que cria uma malha tridimensional com aberturas em forma de diamante elevadas. Este processo proporciona uma excelente relação resistência-peso e capacidades superiores de drenagem.

Principais Características:

- Superior resistência ao deslizamento devido ao perfil de superfície elevada

- Excelentes propriedades de drenagem e ventilação

- Alta relação resistência-peso

- Alternativa econômica às placas perfuradas

- Fácil de fabricar e instalar

- Design de superfície autolimpante

Processo de Fabricação: Produzido por meio de corte e estiramento simultâneos de chapas de aço em uma única operação, criando um padrão de diamante elevado sem desperdício de material. O processo de expansão endurece o material, aumentando sua resistência.

Aplicações: Pisos industriais, passarelas, plataformas, degraus de escadas, barreiras de segurança, telas de ventilação, aplicações de filtração, fachadas arquitetônicas e sistemas de grelhas de segurança.

🧪 Chemical Composition

| Elemento | Mín % | Máx % | Típico % | Requisito ASTM A36 |

|---|---|---|---|---|

| Carbono (C) | - | 0.26 | 0.18 | ≤ 0.26 |

| Manganês (Mn) | 0.80 | 1.20 | 0.95 | 0.80-1.20 |

| Silício (Si) | 0.15 | 0.40 | 0.25 | 0.15-0.40 |

| Fósforo (P) | - | 0.040 | 0.025 | ≤ 0.040 |

| Enxofre (S) | - | 0.050 | 0.030 | ≤ 0.050 |

| Cobre (Cu) | - | 0.20 | 0.15 | ≤ 0.20 |

| Cromo (Cr) | - | 0.30 | 0.15 | ≤ 0.30 |

| Níquel (Ni) | - | 0.30 | 0.15 | ≤ 0.30 |

| Ferro (Fe) | Equilíbrio | Equilíbrio | 98.2 | Equilíbrio |

⚙️ Mechanical Properties

| Propriedade | Requisito ASTM | Valor Típico | Método de Teste | Temperatura |

|---|---|---|---|---|

| Resistência à Tração | 400-550 MPa | 450 MPa | ASTM A370 | Temperatura Ambiente |

| Resistência ao Escoamento | 250 MPa min | 280 MPa | ASTM A370 | Temperatura Ambiente |

| Alongamento | 20% min | 25% | ASTM A370 | Temperatura Ambiente |

| Dureza (Brinell) | - | 120-140 HB | ASTM E10 | Temperatura Ambiente |

| Dureza (Rockwell B) | - | 70-80 HRB | ASTM E18 | Temperatura Ambiente |

| Módulo de Elasticidade | - | 200 GPa | ASTM E111 | Temperatura Ambiente |

| Energia de Impacto (Charpy V) | - | 80+ J | ASTM E23 | Temperatura Ambiente |

🔬 Physical Properties

| Propriedade | Valor | Unidade | Temperatura | Norma de Teste |

|---|---|---|---|---|

| Densidade | 7.85 | g/cm3 | 20°C | ASTM B311 |

| Ponto de Fusão | 1425-1540 | °C | - | Análise DSC |

| Condutividade Térmica | 50.2 | W/m·K | 100°C | ASTM E1461 |

| Calor Específico | 460 | J/kg·K | 0-100°C | ASTM C351 |

| Expansão Linear | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| Resistividade Elétrica | 170 | n|°¤m | 20°C | ASTM B193 |

| Permeabilidade Magnética | Alta | μ/μ₀ | Temperatura Ambiente | ASTM A342 |

| Temperatura de Curie | 770 | °C | - | Ferromagnético |

📏 Product Specifications

| Especificação | Faixa Disponível | Tamanho Padrão | Personalizado Disponível | Tolerância |

|---|---|---|---|---|

| Espessura da Folha | 0.5mm - 8mm | 1.5mm - 3mm | Sim | ±0.1mm |

| Abertura da Malha (LWD) | 3mm - 100mm | 10mm - 50mm | Sim | ±0.5mm |

| Abertura da Malha (SWD) | 2mm - 50mm | 5mm - 25mm | Sim | ±0.3mm |

| Largura do Fio | 1mm - 10mm | 2mm - 6mm | Sim | ±0.2mm |

| Altura Elevada | 3mm - 25mm | 6mm - 15mm | Sim | ±1mm |

| Tamanho da Folha | 1m?á2m - 2.5m?á6m | 1.22m?á2.44m | Sim | ±5mm |

| Acabamento da Superfície | Fresado, Galvanizado, Pintado | Acabamento Fresado | Sim | Padrão |

| Área Aberta | 40% - 80% | 60% - 70% | Calculado | ±2% |

| Conformidade com Normas | ASTM F1267, ISO 4762 | ASTM F1267 | Múltiplas | Conformidade total |

| Embalagem | Paletes, Feixes, Caixas | Paletes | Personalizado | Padrão de exportação |

Vamos Criar Sucesso para o Seu Projeto

Equipe Profissional, Produtos Premium, Serviço Completo - O Sucesso do Seu Projeto é Nossa Missão

Our Advantages in Processing Malha Metálica Expandida em Aço

Tecnologia de Corte de Precisão

O processo avançado de corte garante cortes uniformes e precisos em chapas de aço, criando padrões de malha consistentes com especificações exatas. Essa tecnologia permite tolerâncias dimensionais apertadas e superior integridade estrutural em grandes lotes de produção.

Processo de Alongamento Controlado

Equipamento de alongamento especializado aplica força calibrada para expandir o metal uniformemente, criando aberturas em forma de diamante precisas enquanto mantém a resistência do material. Este processo otimiza o equilíbrio entre o uso de material e o desempenho estrutural.

Formação de Padrão Elevado

Técnicas de formação inovadoras criam superfícies elevadas durante o processo de expansão, resultando em características de aderência aprimoradas e aumento da rigidez do material. Esta estrutura tridimensional agrega valor por meio de segurança e desempenho estrutural melhorados.

SEU CONFIÁVEL AÇO

PARCEIRO DE MANUFATURA

Quick Inquiry

Indústrias que Atendemos

Soluções de aço profissionais em grandes indústrias

Qualificações e Certificações