20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

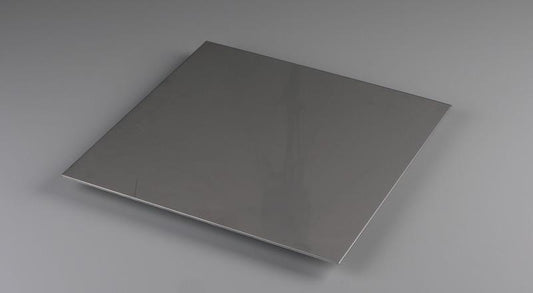

Product Overview

Pickled and Oiled Steel Plate is manufactured from high-quality carbon steel that undergoes a specialized surface treatment process. The pickling process removes mill scale and surface oxides using acid solutions, followed by oil application to prevent corrosion and improve surface quality.

Key Features:

- Superior surface finish with scale-free appearance

- Enhanced corrosion resistance through oil coating

- Excellent formability and weldability

- Consistent thickness and flatness tolerances

- Ready for painting and coating applications

Manufacturing Process: Hot rolled steel is pickled in hydrochloric or sulfuric acid baths to remove scale, then rinsed, dried, and coated with a thin layer of oil for protection during storage and transportation.

Applications: Automotive components, appliance manufacturing, construction materials, general fabrication, stamping and forming operations, and applications requiring superior surface finish prior to painting or coating.

🧪 Chemical Composition

| Element | Min % | Max % | Typical % | ASTM A1011 Requirement |

|---|---|---|---|---|

| Carbon (C) | - | 0.15 | 0.08 | ≤ 0.15 |

| Manganese (Mn) | 0.30 | 0.90 | 0.60 | 0.30-0.90 |

| Phosphorus (P) | - | 0.030 | 0.015 | ≤ 0.030 |

| Sulfur (S) | - | 0.035 | 0.020 | ≤ 0.035 |

| Silicon (Si) | - | 0.40 | 0.15 | ≤ 0.40 |

| Aluminum (Al) | 0.020 | 0.080 | 0.040 | 0.020-0.080 |

| Nitrogen (N) | - | 0.009 | 0.005 | ≤ 0.009 |

| Copper (Cu) | - | 0.20 | 0.10 | ≤ 0.20 |

| Iron (Fe) | Balance | Balance | 98.8 | Balance |

⚙️ Mechanical Properties

| Property | ASTM Requirement | Typical Value | Test Method | Temperature |

|---|---|---|---|---|

| Tensile Strength | 270-410 MPa | 340 MPa | ASTM A370 | Room Temp |

| Yield Strength | 140 MPa min | 180 MPa | ASTM A370 | Room Temp |

| Elongation | 22% min | 28% | ASTM A370 | Room Temp |

| Hardness (Brinell) | - | 120 HB | ASTM E10 | Room Temp |

| Hardness (Rockwell B) | - | 65 HRB | ASTM E18 | Room Temp |

| Modulus of Elasticity | - | 200 GPa | ASTM E111 | Room Temp |

| Impact Energy (Charpy V) | - | 150+ J | ASTM E23 | Room Temp |

🔬 Physical Properties

| Property | Value | Unit | Temperature | Test Standard |

|---|---|---|---|---|

| Density | 7.85 | g/cm3 | 20°C | ASTM B311 |

| Melting Point | 1510-1540 | °C | - | DSC Analysis |

| Thermal Conductivity | 50.2 | W/m·K | 100°C | ASTM E1461 |

| Specific Heat | 460 | J/kg·K | 0-100°C | ASTM C351 |

| Linear Expansion | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| Electrical Resistivity | 170 | n|°¤m | 20°C | ASTM B193 |

| Magnetic Permeability | High | μ/μ₀ | Room Temp | ASTM A342 |

| Curie Temperature | 770 | °C | - | Ferromagnetic |

📏 Product Specifications

| Specification | Available Range | Standard Size | Custom Available | Tolerance |

|---|---|---|---|---|

| Thickness | 1.2mm - 12.7mm | Various | Yes | ±0.05mm |

| Width | 600mm - 2100mm | 1250mm, 1500mm | Yes | ±3mm |

| Length | 2000mm - 12000mm | 6000mm | Yes | +50mm/-0mm |

| Surface Finish | Pickled & Oiled | P&O Standard | Special finish | Ra ≤ 1.6μm |

| Edge Condition | Mill Edge, Slit Edge | Mill Edge | Yes | ASTM A1011 |

| Flatness | ≤ 5mm/m | Standard | Precision flat | ASTM A1011 |

| Standards Compliance | ASTM A1011, A569, A635 | A1011 | Multiple | Full compliance |

| Steel Grade | CS Type A, B, C | CS Type B | Yes | Grade certified |

| Test Certificate | Mill TC, EN 10204 3.1 | Mill TC | Yes | Standard |

| Packaging | Coils, Cut Sheets | Cut Sheets | Custom | Export standard |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing Pickled and Oiled Steel Plate

Superior Surface Cleanliness

The pickling process effectively removes surface contaminants, mill scale, and rust through chemical treatment, resulting in an exceptionally clean steel surface that's ideal for subsequent processing and finishing operations.

Enhanced Corrosion Protection

The combination of pickling followed by precise oil application creates a dual protective barrier against corrosion, significantly extending the material's shelf life and providing superior resistance to environmental factors.

Improved Processing Quality

The smooth, clean surface achieved through the pickle-and-oil process ensures better paint adhesion, easier forming operations, and enhanced weldability, making it ideal for demanding manufacturing applications.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications