20 Years Experience | 1000+ Brand Partners | Full Customization

We have 20 years of industry experience, have partnered with over 1,000 brands, and support any customization needs.

Technical Specifications

Product Overview

Metallurgical Characteristics

EN S460 is a high-strength low-alloy (HSLA) structural steel produced through thermomechanical controlled processing (TMCP). The steel features a fine-grained ferrite-pearlite microstructure achieved through controlled rolling and accelerated cooling, providing excellent combination of strength, toughness, and weldability. Microalloying elements such as vanadium, niobium, and titanium contribute to grain refinement and precipitation strengthening.

Heat Treatment and Processing

MetalZenith employs advanced thermomechanical rolling processes with precise temperature control between 1050-1200°C during reheating, followed by controlled rolling in the temperature range of 900-1050°C. The final rolling passes occur below the recrystallization temperature to achieve optimal grain refinement. Accelerated cooling may be applied to enhance mechanical properties and achieve desired microstructural characteristics.

Manufacturing Process Excellence

Our state-of-the-art production line features computer-controlled rolling mills with advanced automation systems ensuring consistent thickness tolerance and surface quality. The process includes continuous casting, slab reheating in walking beam furnaces, multi-pass rolling with online thickness measurement, and controlled cooling systems. Real-time monitoring of temperature, reduction ratios, and cooling rates ensures optimal mechanical properties throughout the entire coil or plate.

Quality Standards and Compliance

EN S460 production at MetalZenith complies with EN 10025-2 standard requirements and additional international specifications including ASTM A572 Grade 65 and JIS G3106 SM490. Our quality management system encompasses chemical composition control through ladle metallurgy, mechanical property verification through standardized testing procedures, and dimensional accuracy verification using laser measurement systems. All products undergo ultrasonic testing for internal soundness and surface inspection for defect detection.

🧪 Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.20 |

| Manganese (Mn) | ≤ 1.70 |

| Silicon (Si) | ≤ 0.55 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.025 |

| Nitrogen (N) | ≤ 0.015 |

| Chromium (Cr) | ≤ 0.30 |

| Nickel (Ni) | ≤ 0.50 |

| Molybdenum (Mo) | ≤ 0.10 |

| Copper (Cu) | ≤ 0.55 |

| Aluminum (Al) | ≥ 0.015 |

| Vanadium (V) | ≤ 0.12 |

| Niobium (Nb) | ≤ 0.05 |

| Titanium (Ti) | ≤ 0.05 |

⚙️ Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength (ReH) | 460-620 MPa |

| Tensile Strength (Rm) | 540-720 MPa |

| Elongation (A5) | ≥ 17% |

| Impact Energy (KV) at 20°C | ≥ 27 J |

| Impact Energy (KV) at 0°C | ≥ 40 J |

| Impact Energy (KV) at -20°C | ≥ 27 J |

| Hardness (HB) | 150-220 |

| Young's Modulus | 210 GPa |

| Shear Modulus | 81 GPa |

| Poisson's Ratio | 0.30 |

| Fatigue Limit (10^7 cycles) | 230-280 MPa |

| Reduction of Area | ≥ 40% |

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1510°C |

| Thermal Conductivity (20°C) | 54 W/m·K |

| Thermal Expansion Coefficient (20-100°C) | 12×10-6/K |

| Thermal Expansion Coefficient (20-200°C) | 13×10-6/K |

| Thermal Expansion Coefficient (20-400°C) | 14×10-6/K |

| Specific Heat Capacity | 500 J/kg·K |

| Electrical Resistivity (20°C) | 0.16 µΩ·m |

| Magnetic Permeability | Ferromagnetic |

| Curie Temperature | 770°C |

| Thermal Diffusivity | 13.7 mm²/s |

| Coefficient of Thermal Expansion (Linear) | 11.5×10-6/K |

📏 Product Specifications

| Specification | Details |

|---|---|

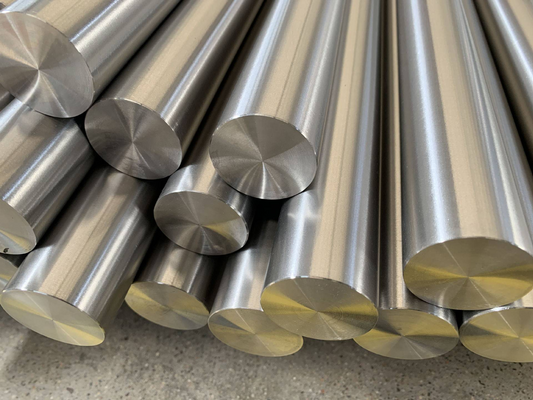

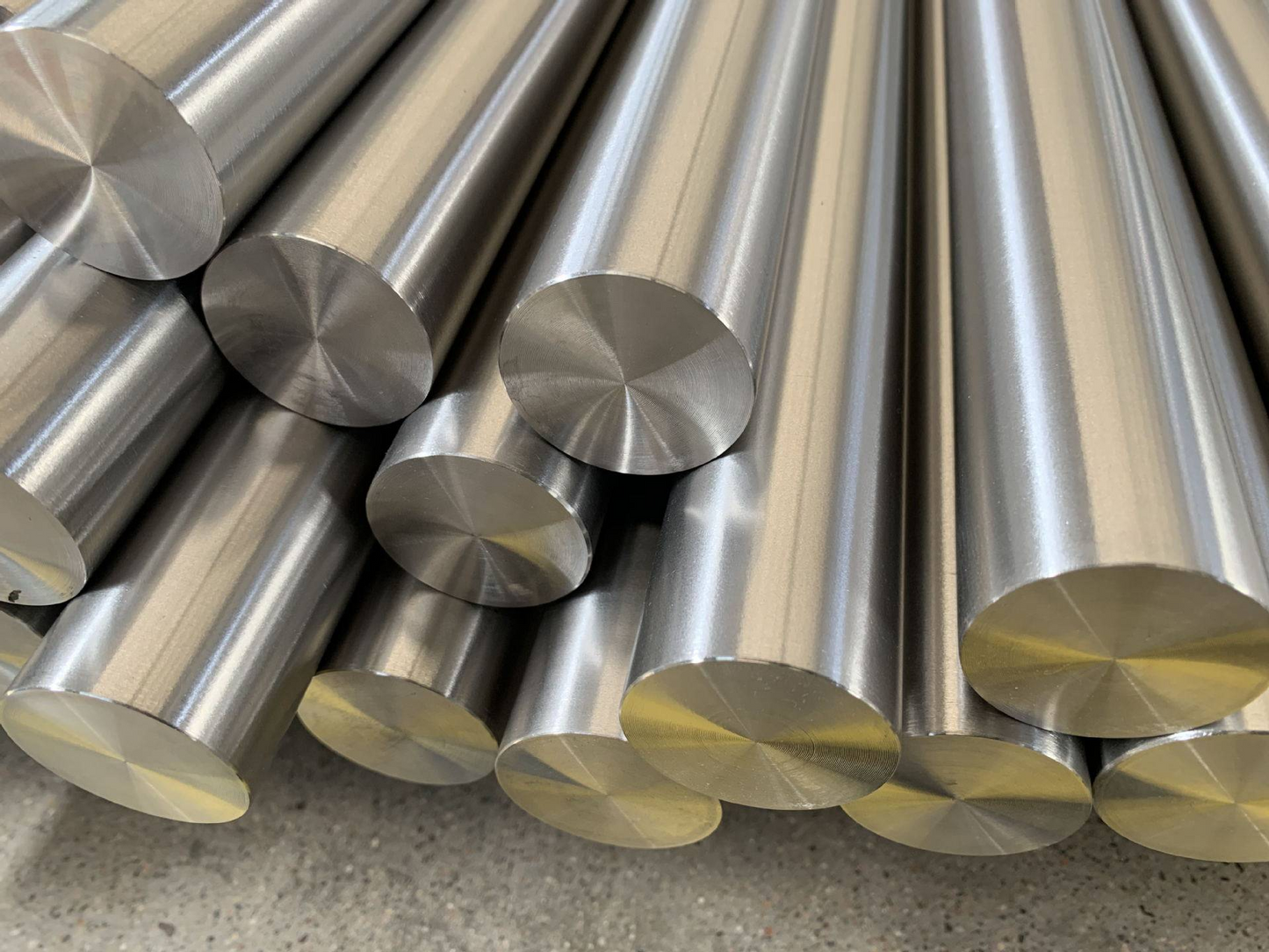

| Available Forms | Plates, Sheets, Bars, Beams, Channels, Angles, Tubes |

| Plate Thickness Range | 3-150 mm |

| Sheet Thickness Range | 0.5-3 mm |

| Bar Diameter Range | 10-300 mm |

| Standard Widths | 1000-3000 mm |

| Standard Lengths | 6000-12000 mm |

| Surface Finish | Hot Rolled, Pickled, Shot Blasted, Machined |

| Edge Condition | Mill Edge, Sheared, Flame Cut, Machined |

| Dimensional Tolerance | EN 10029, EN 10051, EN 10058 |

| Applicable Standards | EN 10025-2, ASTM A572, JIS G3106 |

| Delivery Condition | Thermomechanically Rolled (+TM) |

| Quality Grades | S460M, S460ML, S460N, S460NL |

| Testing Requirements | 3.1 Certificate, 3.2 Certificate Available |

Let Us Create Success for Your Project

Professional Team, Premium Products, Complete Service - Your Project Success is Our Mission

Our Advantages in Processing EN S460

Advanced Thermomechanical Processing

MetalZenith employs cutting-edge controlled rolling technology with precise temperature monitoring and automated process control, ensuring optimal grain structure and superior mechanical properties in every batch of EN S460 steel.

Comprehensive Quality Control System

Our ISO 9001:2015 certified facility features advanced testing laboratories with spectroscopic analysis, mechanical testing equipment, and non-destructive testing capabilities, guaranteeing consistent quality and full material traceability.

Global Supply Chain Excellence

With strategic partnerships worldwide and flexible production scheduling, MetalZenith delivers customized EN S460 products in various forms and sizes, supported by technical expertise and reliable logistics networks.

YOUR TRUSTED STEEL

MANUFACTURING PARTNER

Quick Inquiry

Industries We Serve

Professional steel solutions across major industries

Qualifications & Certifications