20年の経験 | 1000以上のブランドパートナー | 完全なカスタマイズ

私たちは20年の業界経験があり、1,000以上のブランドと提携し、あらゆるカスタマイズニーズをサポートしています。

Technical Specifications

Product Overview

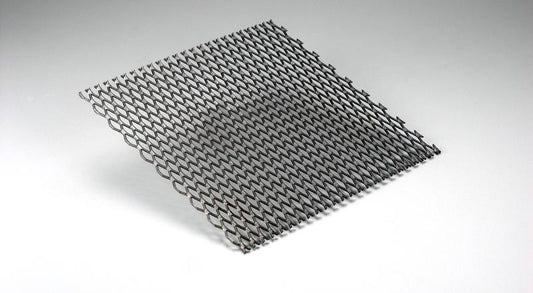

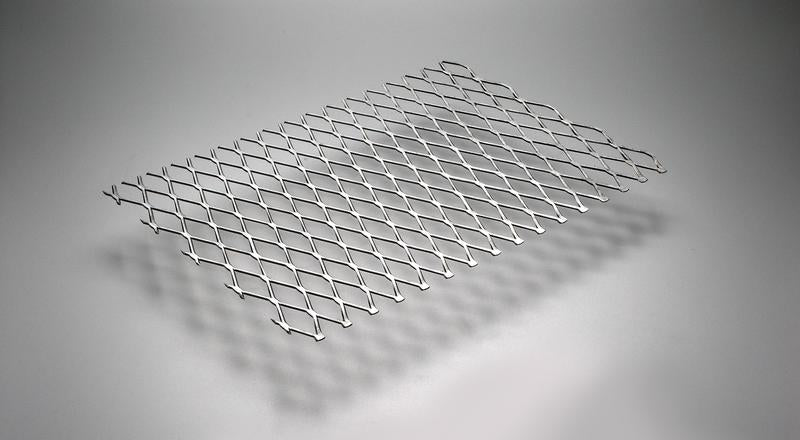

スチールフラットエクスパンドメタルは、高品質の炭素鋼から精密な拡張および平坦化プロセスを通じて製造されています。この多用途の金属メッシュ製品は、優れた強度対重量比と優れた通気性を提供し、産業および建築用途に最適です。

主な特徴:

- 優れた剛性を持つ高い強度対重量比

- 優れた通気性と排水能力

- 安全用途のための滑り止め表面テクスチャ

- 穿孔シートのコスト効果的な代替品

- 優れた塗料およびコーティングの接着特性

製造プロセス:鋼板の精密スリットおよび拡張を経て、均一な厚さと滑らかな表面仕上げを作成するために平坦化プロセスを行います。

用途:産業用床、歩道、プラットフォーム、セキュリティフェンシング、フィルトレーションシステム、通気口、建築ファサード、一般的なスクリーニング用途。

🧪 Chemical Composition

Chemical Composition:

| 元素 | 最小 % | 最大 % | 典型 % | ASTM F1267 要求 |

|---|---|---|---|---|

| 炭素 (C) | - | 0.25 | 0.18 | ≤ 0.25 |

| マンガン (Mn) | 0.30 | 1.50 | 0.85 | 0.30-1.50 |

| シリコン (Si) | - | 0.40 | 0.25 | ≤ 0.40 |

| リン (P) | - | 0.040 | 0.025 | ≤ 0.040 |

| 硫黄 (S) | - | 0.050 | 0.030 | ≤ 0.050 |

| アルミニウム (Al) | - | 0.10 | 0.05 | ≤ 0.10 |

| 銅 (Cu) | - | 0.35 | 0.20 | ≤ 0.35 |

| 窒素 (N) | - | 0.012 | 0.008 | ≤ 0.012 |

| 鉄 (Fe) | バランス | バランス | 98.2 | バランス |

⚙️ Mechanical Properties

機械的特性:

| 特性 | ASTM 要求 | 典型値 | 試験方法 | 温度 |

|---|---|---|---|---|

| 引張強度 | 400 MPa 最小 | 450 MPa | ASTM A370 | 室温 |

| 降伏強度 (0.2%) | 250 MPa 最小 | 280 MPa | ASTM A370 | 室温 |

| 伸び | 20% 最小 | 25% | ASTM A370 | 室温 |

| 硬度 (ブリネル) | - | 130 HB | ASTM E10 | 室温 |

| 硬度 (ロックウェル B) | - | 75 HRB | ASTM E18 | 室温 |

| 弾性係数 | - | 200 GPa | ASTM E111 | 室温 |

| 衝撃エネルギー (シャルピー V) | - | 80+ J | ASTM E23 | 室温 |

🔬 Physical Properties

物理特性:

| 特性 | 値 | 単位 | 温度 | 試験基準 |

|---|---|---|---|---|

| 密度 | 7.85 | g/cm3 | 20°C | ASTM B311 |

| 融点 | 1510-1540 | °C | - | DSC分析 |

| 熱伝導率 | 50.2 | W/m·K | 100°C | ASTM E1461 |

| 比熱 | 460 | J/kg·K | 0-100°C | ASTM C351 |

| 線膨張 | 11.7 | μm/m·K | 0-100°C | ASTM E228 |

| 電気抵抗率 | 170 | n|°¤m | 20°C | ASTM B193 |

| 磁気透過率 | 高い | μ/μ₀ | 室温 | ASTM A342 |

| キュリー温度 | 770 | °C | - | 強磁性 |

📏 Product Specifications

製品仕様:

| 仕様 | 利用可能範囲 | 標準サイズ | カスタム利用可能 | 公差 |

|---|---|---|---|---|

| シート厚さ | 0.5mm - 8mm | 2mm | はい | ±0.1mm |

| シート幅 | 600mm - 2000mm | 1220mm | はい | ±5mm |

| シート長さ | 1000mm - 6000mm | 2440mm | はい | ±10mm |

| メッシュ開口部 (LWD) | 3mm - 100mm | 20mm | はい | ±1mm |

| メッシュ開口部 (SWD) | 2mm - 50mm | 10mm | はい | ±0.5mm |

| ストランド幅 | 1mm - 10mm | 3mm | はい | ±0.2mm |

| 開放面積 | 40% - 85% | 65% | はい | ±3% |

| 表面仕上げ | ミル, 亜鉛メッキ, PVCコーティング | ミル | はい | ASTM A123 |

| 規格適合 | ASTM F1267, ISO 606 | ASTM F1267 | 複数 | 完全適合 |

| 包装 | パレット, バンドル, クレート | パレット | カスタム | 輸出標準 |

あなたのプロジェクトの成功を共に創りましょう

プロフェッショナルチーム、プレミアム製品、完全なサービス - あなたのプロジェクトの成功は私たちの使命です

Our Advantages in Processing スチールフラットエクスパンドメタル

精密カットとストレッチ

高度な製造プロセスは、高精度の切断と制御された引き伸ばし技術を使用して、鋼板全体に均一なメッシュパターンを作成し、材料表面全体で一貫した間隔とストランドの厚さを確保します。

制御されたフラットニングプロセス

特殊なローリング機器は、膨張金属表面を平坦にするために正確な圧力を適用し、材料の安定性を高め、表面接触面積を改善しながら、構造的完全性を維持する滑らかで平らな面を作り出します。

最適化された材料効率

拡張プロセスは、材料の無駄を出さずに開口部を作成することによって原材料の使用を最大化し、全体の材料コストと環境への影響を減らしながら、構造的強度を維持した軽量製品を実現します。

あなたの信頼できる 鋼

製造パートナー

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

20

年数の経験

鋼鉄製造および流通のリーディング

1000以上

ブランドパートナー

グローバル業界のリーダーに信頼されています

完全

カスタマイズ

すべてのプロジェクトに合わせたソリューション

50M+

配達されたトン数

高品質の鋼製品を世界中に

95%

クライアントの維持

長期的なパートナーシップの成功

ISO 9001

認証された品質

国際標準の遵守

お問い合わせ

クイックお問い合わせ

最小注文数量:3トン

私たちが提供する業界

主要産業向けのプロフェッショナルな鋼ソリューション

資格と認証