20 Tahun Pengalaman | 1000+ Mitra Merek | Kustomisasi Penuh

Kami memiliki 20 tahun pengalaman industri, telah bermitra dengan lebih dari 1.000 merek, dan mendukung kebutuhan kustomisasi apa pun.

Technical Specifications

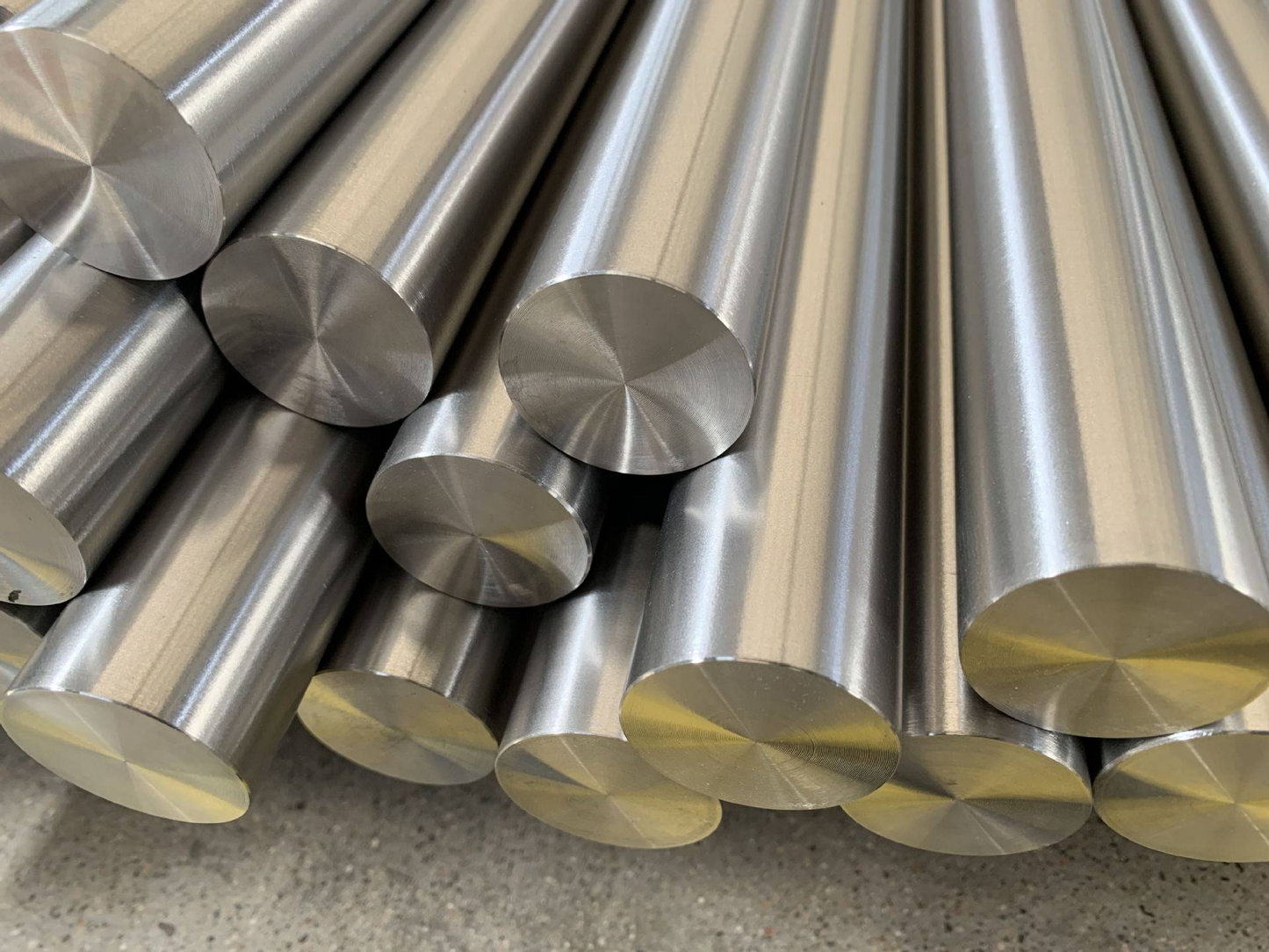

Product Overview

Karakteristik Metalurgi

ETD 150 memiliki mikrostruktur martensitik yang dikeraskan dengan butiran halus yang dicapai melalui proses pendinginan dan tempering yang terkontrol. Komposisi paduan yang dioptimalkan dengan tambahan krom, nikel, dan molibdenum memberikan kemampuan pengerasan yang lebih baik dan sifat mekanik yang ditingkatkan. Struktur butiran yang halus memastikan keseimbangan kekuatan-ketangguhan yang sangat baik yang penting untuk aplikasi struktural.

Proses Perlakuan Panas

MetalZenith menerapkan austenitisasi terkontrol pada 850-900°C diikuti dengan pendinginan air dan tempering pada 580-620°C. Siklus perlakuan panas yang tepat ini memastikan sifat mekanik yang optimal sambil mempertahankan karakteristik las dan pembentukan yang sangat baik yang diperlukan untuk fabrikasi struktural.

Proses Manufaktur

Produksi ETD 150 kami menggunakan peleburan furnace busur listrik dengan pemurnian sekunder, pengecoran kontinu, dan proses penggulungan terkontrol. Kontrol kualitas yang canggih mencakup pemantauan suhu secara real-time, pengujian ultrasonik, dan verifikasi sifat mekanik yang komprehensif untuk memastikan kinerja struktural yang konsisten.

Pengujian Kualitas Struktural

MetalZenith melakukan pengujian ekstensif yang spesifik untuk aplikasi struktural termasuk penilaian kemampuan las sesuai dengan AWS D1.1, evaluasi kinerja pembentukan, pengujian kekuatan kelelahan di bawah beban siklik, dan pengujian ketahanan korosi atmosfer. Pengujian khusus ini memastikan kinerja optimal dalam lingkungan konstruksi dan rekayasa.

Rekayasa Aplikasi

Untuk konstruksi bangunan, ETD 150 memberikan rasio kekuatan-terhadap-berat yang sangat baik yang memungkinkan desain struktural yang lebih ringan. Dalam rekayasa jembatan, ketahanan kelelahan yang superior memastikan daya tahan jangka panjang di bawah beban dinamis. Untuk manufaktur mesin, kemampuan mesin dan kemampuan las yang sangat baik memfasilitasi fabrikasi yang kompleks. Dalam konstruksi kendaraan, kekuatan tinggi memungkinkan pengurangan berat sambil mempertahankan standar keselamatan. Aplikasi rekayasa umum mendapatkan manfaat dari kemampuan pembentukan yang serbaguna dan sifat mekanik yang dapat diandalkan.

🧪 Chemical Composition

| Elemen | Komposisi (%) |

|---|---|

| Karbon (C) | 0.15 - 0.23 |

| Mangan (Mn) | 1.20 - 1.65 |

| Silikon (Si) | 0.15 - 0.40 |

| Fosfor (P) | ≤ 0.030 |

| Belerang (S) | ≤ 0.030 |

| Krom (Cr) | 0.30 - 0.65 |

| Nikel (Ni) | 0.25 - 0.50 |

| Molybdenum (Mo) | 0.15 - 0.25 |

⚙️ Mechanical Properties

| Properti | Nilai |

|---|---|

| Kekuatan Tarik (MPa) | ≥ 550 |

| Kekuatan Tarik (MPa) | 650 - 850 |

| Panjang Regangan (%) | ≥ 18 |

| Energi Impak pada 0°C (J) | ≥ 35 |

| Kekerasan (HB) | 180 - 250 |

| Kekuatan Fatigue (MPa) | 280 - 320 |

🔬 Physical Properties

| Properti | Nilai |

|---|---|

| Kepadatan (g/cm3) | 7.85 |

| Titik Leleh (°C) | 1480 - 1520 |

| Konduktivitas Termal (W/m·K) | 42.5 |

| Ekspansi Termal (×10??/K) | 11.8 |

| Modulus Elastis (GPa) | 210 |

| Rasio Poisson | 0.27 - 0.30 |

📏 Product Specifications

| Spesifikasi | Detail |

|---|---|

| Bentuk Tersedia | Pelat, Balok, Saluran, Sudut, Batang, Tabung |

| Rentang Ketebalan | 8 - 150mm |

| Rentang Lebar | 1200 - 3500mm |

| Rentang Panjang | 6000 - 15000mm |

| Kepatuhan Standar | ASTM A572, EN 10025-6, JIS G3106 |

| Kondisi Perlakuan Panas | Dikuatkan dan Ditemper (Q&T) |

| Penyelesaian Permukaan | Dibuat Panas, Dicuci, Ditembak |

Mari Kita Ciptakan Kesuksesan untuk Proyek Anda

Tim Profesional, Produk Premium, Layanan Lengkap - Keberhasilan Proyek Anda adalah Misi Kami

Our Advantages in Processing ETD 150 Steel

Pemrosesan Termomekanik Lanjutan

MetalZenith memanfaatkan penggulungan terkontrol dengan pengendalian suhu yang tepat diikuti dengan pendinginan yang dipercepat untuk mencapai mikrostruktur yang optimal pada baja ETD 150. Teknologi pemrosesan canggih kami memastikan pemurnian butir yang seragam dan peningkatan sifat mekanik, memberikan kekuatan dan ketangguhan yang superior untuk aplikasi struktural.

Pengujian Struktur Komprehensif

Baja ETD 150 kami menjalani pengujian yang ekstensif termasuk penilaian kemampuan pengelasan, evaluasi kinerja pembentukan, pengujian kekuatan kelelahan, dan analisis ketahanan korosi atmosfer. Program jaminan kualitas MetalZenith memastikan kinerja optimal dalam aplikasi struktural dengan daya tahan jangka panjang yang terverifikasi.

Solusi Struktur Kustom

MetalZenith menyediakan layanan kustomisasi komprehensif untuk baja ETD 150 termasuk pemotongan presisi, pembentukan, optimasi perlakuan panas, dan persiapan permukaan. Tim dukungan teknis kami bekerja sama dengan insinyur struktural untuk memberikan solusi yang disesuaikan untuk kebutuhan konstruksi dan rekayasa tertentu.

ANDA YANG DIPERCAYA BAJA

MITRA MANUFAKTUR

Pertanyaan Cepat

Industri yang Kami Layani

Solusi baja profesional di berbagai industri

Kualifikasi & Sertifikasi