20 años de experiencia | Más de 1000 marcas asociadas | Personalización completa

Tenemos 20 años de experiencia en la industria, nos hemos asociado con más de 1000 marcas y apoyamos cualquier necesidad de personalización.

Technical Specifications

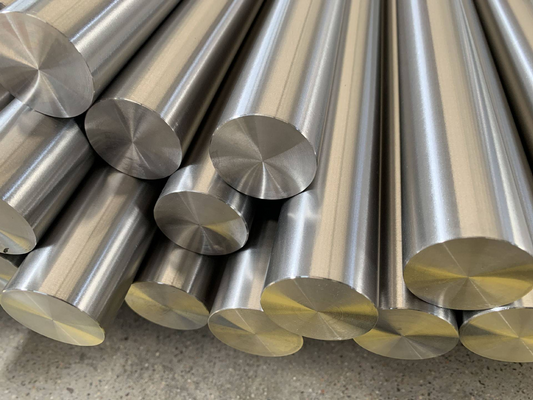

Product Overview

Características metalúrgicas

El acero API 5L X70 presenta una microestructura de ferrita-perlita de grano fino, lograda mediante un procesamiento termomecánico controlado. Su mayor resistencia se debe al fortalecimiento por solución sólida, el refinamiento del grano y los mecanismos de endurecimiento por precipitación. Elementos de microaleación como el niobio, el vanadio y el titanio contribuyen al refinamiento del grano y al fortalecimiento por precipitación, manteniendo al mismo tiempo excelentes propiedades de soldabilidad y tenacidad.

Proceso de fabricación

MetalZenith emplea tecnología avanzada de laminado controlado, seguido de enfriamiento acelerado, para producir acero API 5L X70. El proceso comienza con la fabricación de acero en horno de arco eléctrico, seguido del refinado en cuchara y la colada continua. El laminado en caliente se realiza bajo condiciones de temperatura y deformación controladas con precisión, optimizando las temperaturas de laminado de acabado para lograr el tamaño de grano de austenita deseado. El enfriamiento acelerado inmediatamente después del laminado garantiza una cinética de transformación óptima y el desarrollo de la microestructura.

Consideraciones sobre el tratamiento térmico

El acero API 5L X70 se suministra generalmente en estado laminado y no requiere tratamiento térmico posterior al laminado. Sin embargo, se puede aplicar un recocido de alivio de tensiones a 580-620 °C después de las operaciones de soldadura o conformado. El acero presenta una excelente soldabilidad, con temperaturas de precalentamiento que suelen oscilar entre 50 y 150 °C, dependiendo del espesor y las condiciones ambientales. Generalmente, no se requiere tratamiento térmico posterior a la soldadura en la mayoría de las aplicaciones.

Estándares de calidad y pruebas

La producción de acero API 5L X70 de MetalZenith se rige por estrictos protocolos de control de calidad, que incluyen la verificación de la composición química, pruebas de propiedades mecánicas, análisis no destructivos e inspección dimensional. Todos los productos se someten a pruebas hidrostáticas, inspección ultrasónica y pruebas de impacto Charpy V-notch. Nuestro sistema de gestión de calidad está certificado según las normas ISO 9001:2015, API Q1 y otras normas internacionales, lo que garantiza una calidad constante del producto y una trazabilidad completa desde la materia prima hasta el producto terminado.

🧪 Chemical Composition

| Elemento | Composición (%) |

|---|---|

| Carbono (C) | ≤ 0,22 |

| Manganeso (Mn) | 1,40 - 1,85 |

| Silicio (Si) | ≤ 0,45 |

| Fósforo (P) | ≤ 0,025 |

| Azufre (S) | ≤ 0,015 |

| Cromo (Cr) | ≤ 0,30 |

| Níquel (Ni) | ≤ 0,30 |

| Molibdeno (Mo) | ≤ 0,15 |

| Cobre (Cu) | ≤ 0,50 |

| Niobio (Nb) | ≤ 0,05 |

| Vanadio (V) | ≤ 0,10 |

| Titanio (Ti) | ≤ 0,06 |

| Aluminio (Al) | ≤ 0,06 |

| Equivalente de carbono (CE) | ≤ 0,43 |

⚙️ Mechanical Properties

| Propiedad | Valor |

|---|---|

| Límite elástico (Rt0,5) | 485 - 635 MPa |

| Resistencia a la tracción (Rm) | 570 - 760 MPa |

| Elongación (A) | ≥ 18% |

| Relación entre rendimiento y tracción | ≤ 0,93 |

| Dureza (HV10) | 200 - 280 |

| Energía de impacto (CVN a 0 °C) | ≥ 40 J |

| Energía de impacto (CVN a -20 °C) | ≥ 27 J |

| Límite de fatiga ( 107 ciclos) | 240 MPa |

| Tenacidad a la fractura (K1c) | 150 - 200 MPa·m 0,5 |

| Módulo de Young | 210 GPa |

| Coeficiente de Poisson | 0.30 |

| Módulo de corte | 80 GPa |

🔬 Physical Properties

| Propiedad | Valor |

|---|---|

| Densidad | 7,85 g/cm³ |

| Punto de fusión | 1510°C |

| Conductividad térmica (20 °C) | 54 W/m·K |

| Coeficiente de expansión térmica (20-100 °C) | 12×10 -6 /K |

| Capacidad calorífica específica | 500 J/kg·K |

| Resistividad eléctrica (20 °C) | 0,16 µΩ·m |

| Permeabilidad magnética | Ferromagnético |

| Temperatura de Curie | 770°C |

| Difusividad térmica | 13,7 mm²/s |

| Coeficiente de expansión lineal (0-100 °C) | 11,5×10 -6 /K |

| Emisividad (superficie oxidada) | 0,79 |

📏 Product Specifications

| Especificación | Detalles |

|---|---|

| Formularios disponibles | Tubos sin costura, tubos soldados, placas, láminas, bobinas |

| Rango de diámetro de tubería | 6,35 mm - 1422 mm (0,25' - 56') |

| Rango de espesor de pared | 2,11 mm - 50,8 mm |

| Rango de espesor de placa | 6 mm - 100 mm |

| Rango de longitud | 5,8 m - 18,3 m (longitud aleatoria, doble longitud aleatoria) |

| Normas de fabricación | API 5L, ASTM A106, EN 10208, ISO 3183, CSA Z245.1 |

| Preparación final | Extremo liso, extremo biselado, roscado y acoplado |

| Acabado de la superficie | Negro, barnizado, recubierto de 3PE, recubierto de FBE |

| Tolerancia dimensional | ±1% (OD), ±10% (Espesor de pared) |

| Requisitos de prueba | Prueba hidrostática, END, análisis químico, pruebas mecánicas |

| Proceso de dar un título | Certificado de prueba de fábrica, inspección de terceros disponible |

Permítanos crear el éxito para su proyecto

Equipo profesional, productos premium, servicio completo: el éxito de su proyecto es nuestra misión

Our Advantages in Processing API 5L X70

Procesamiento termomecánico avanzado

MetalZenith utiliza tecnología de vanguardia de laminado controlado y enfriamiento acelerado para lograr un refinamiento óptimo de la microestructura en acero API 5L X70, lo que garantiza propiedades mecánicas superiores y una calidad constante en todo el espesor del material.

Sistema Integral de Control de Calidad

Nuestras instalaciones de pruebas de última generación realizan análisis químicos completos, pruebas mecánicas, inspección ultrasónica y verificación dimensional en cada lote de acero API 5L X70, garantizando el cumplimiento de los estándares internacionales de tuberías y las especificaciones del cliente.

Excelencia en la cadena de suministro global

MetalZenith ofrece opciones de personalización flexibles para acero API 5L X70, incluidos varios diámetros de tubería, espesores de pared y preparaciones de extremos, respaldados por nuestra eficiente red logística global que garantiza una entrega oportuna para proyectos de tuberías en todo el mundo.

TU CONFIANZA ACERO

SOCIO DE FABRICACIÓN

Consulta Rápida

Industrias a las que servimos

Soluciones profesionales de acero para las principales industrias

Cualificaciones y certificaciones