20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

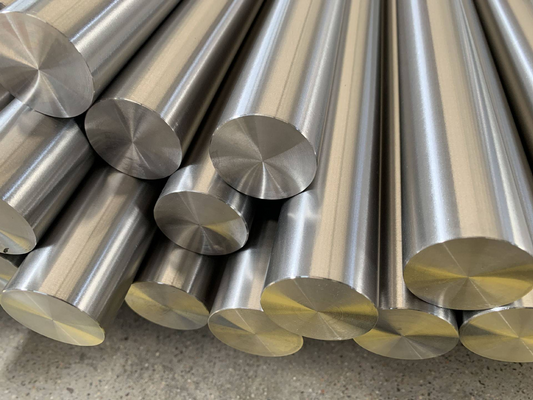

Product Overview

الخصائص المعدنية

SA515 الدرجة 70 هو فولاذ متوسط الكربون مع بنية ميكروية تتكون بشكل أساسي من الفريت والبيرلايت. يوفر محتوى الكربون المتحكم فيه وإضافة المنغنيز توازنًا مثاليًا بين القوة والليونة، بينما يعمل السيليكون كعامل إزالة الأكسدة وكمقوي. الهيكل الحبيبي الدقيق الذي يتم تحقيقه من خلال الدرفلة المتحكم فيها يعزز كل من الخصائص الميكانيكية وقابلية اللحام.

عملية المعالجة الحرارية

تستخدم MetalZenith معالجة حرارية طبيعية لـ SA515 الدرجة 70، تتضمن تسخينًا إلى 900-950°C يتبعه تبريد بالهواء. تعمل هذه العملية على تنقية بنية الحبيبات، وتخفيف الضغوط الداخلية، وضمان خصائص ميكانيكية موحدة في جميع أنحاء سمك المادة. قد يتم تطبيق معالجة تخفيف الضغوط عند 580-650°C لتحسين الاستقرار الأبعاد.

عملية التصنيع

تبدأ عملية التصنيع المتكاملة لدينا بصناعة الفولاذ في فرن القوس الكهربائي باستخدام مواد خام عالية الجودة. يخضع الفولاذ المنصهر لتنقية في القادوس للتحكم الدقيق في الكيمياء وإزالة الغازات. ينتج الصب المستمر ألواح عالية الجودة، والتي يتم درفلتها على الساخن باستخدام مطاحن درفلة تتحكم فيها الكمبيوتر مع جداول دقيقة للحرارة والتقليل لتحقيق خصائص ميكانيكية مثالية.

معايير الجودة والاختبار

تتوافق جميع منتجات SA515 الدرجة 70 التي تصنعها MetalZenith مع مواصفات ASTM A515/A515M و ASME SA-515. تشمل الاختبارات الشاملة التحليل الكيميائي بواسطة طيفية الانبعاث الضوئي، واختبار الشد، واختبار تأثير شارب، وقياس الصلابة، والتفتيش بالموجات فوق الصوتية للسلامة الداخلية. تتوفر شهادات اختبار المصنع وخدمات التفتيش من طرف ثالث عند الطلب.

🧪 Chemical Composition

| العنصر | التكوين (%) |

|---|---|

| الكربون (C) | ≤ 0.31 |

| المنغنيز (Mn) | 0.90-1.20 |

| السيليكون (Si) | 0.13-0.45 |

| الفوسفور (P) | ≤ 0.035 |

| الكبريت (S) | ≤ 0.035 |

| الكروم (Cr) | ≤ 0.25 |

| النيكل (Ni) | ≤ 0.25 |

| الموليبدينوم (Mo) | ≤ 0.08 |

| النحاس (Cu) | ≤ 0.35 |

| الفاناديوم (V) | ≤ 0.02 |

⚙️ Mechanical Properties

| الخاصية | القيمة |

|---|---|

| قوة الشد | 485-620 ميجا باسكال |

| قوة الخضوع (0.2% انحراف) | ≥ 260 ميجا باسكال |

| التمدد في 200 مم | ≥ 21% |

| التمدد في 50 مم | ≥ 17% |

| صلابة برينل (HB) | 137-187 |

| أثر شاربي V-Notch (عند 0°C) | ≥ 27 جول |

| تقليل المساحة | ≥ 38% |

| حد التعب (10^7 دورة) | 240 ميجا باسكال |

| معامل المرونة | 200 جيجا باسكال |

| نسبة بواسون | 0.27-0.30 |

🔬 Physical Properties

| الخاصية | القيمة |

|---|---|

| الكثافة | 7.85 g/cm³ |

| نقطة الانصهار | 1510°C |

| الموصلية الحرارية (عند 100°C) | 54 W/m·K |

| معامل التمدد الحراري (20-100°C) | 12×10-6/K |

| السعة الحرارية النوعية | 500 J/kg·K |

| المقاومة الكهربائية | 0.16 µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي |

| درجة حرارة كوري | 770°C |

| الانتشار الحراري | 13.8 mm²/s |

| أقصى درجة حرارة للخدمة | 480°C |

📏 Product Specifications

| المواصفات | الخيارات المتاحة |

|---|---|

| أشكال المنتج | ألواح، صفائح، لفات، مقطعة إلى الطول |

| نطاق السماكة | 5mm - 200mm |

| نطاق العرض | 1000mm - 4000mm |

| نطاق الطول | 2000mm - 18000mm |

| الامتثال للمعايير | ASTM A515/A515M, ASME SA-515 |

| تشطيب السطح | مدرفل على الساخن، مُعالج، مُنفجر بالرصاص |

| حالة الحافة | حافة المصنع، حافة مقصوصة، قطع بالنار |

| تحمل السماكة | ±0.3mm (5-40mm)، ±0.05×السماكة (>40mm) |

| تحمل العرض | ±5mm |

| تحمل الطول | ±10mm |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing SA515 درجة 70

تكنولوجيا الدرفلة المتقدمة المتحكم بها

تستخدم MetalZenith مطاحن دحرجة دقيقة التحكم مزودة بأنظمة مراقبة درجة الحرارة المتقدمة لتحقيق تحسين مثالي للحبيبات والخصائص الميكانيكية في فولاذ SA515 Grade 70، مما يضمن قوة ومرونة متسقة في جميع سمك المادة.

مختبر اختبار الجودة الشامل

تتميز منشأتنا الحديثة للاختبار بأجهزة طيفية متقدمة، وآلات اختبار عالمية، ومعدات فحص بالموجات فوق الصوتية للتحقق من التركيب الكيميائي، والخصائص الميكانيكية، والسلامة الداخلية، مما يضمن الامتثال لمعايير ASTM A515.

معالجة مخصصة والإمداد العالمي

تقدم MetalZenith إمكانيات تخصيص واسعة تشمل القطع الدقيق، والمعالجة الحرارية، وخدمات إنهاء السطح، مدعومة بشبكة اللوجستيات العالمية لدينا لضمان التسليم في الوقت المناسب لفولاذ SA515 Grade 70 للعملاء في جميع أنحاء العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات