20 سنة من الخبرة | 1000+ شريك علامة تجارية | تخصيص كامل

لدينا 20 عامًا من الخبرة في الصناعة، وقد تعاوننا مع أكثر من 1000 علامة تجارية، وندعم أي احتياجات للتخصيص.

Technical Specifications

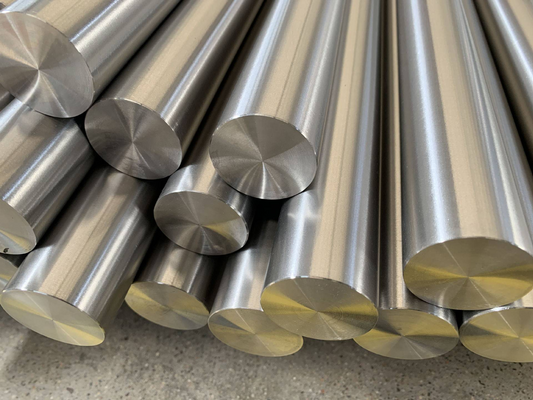

Product Overview

الخصائص المعدنية

GB Q460 هو فولاذ هيكلي عالي القوة ومنخفض السبيكة (HSLA) يتميز بتركيب ميكروهيكلي من الفريت والبرلايت ذو الحبيبات الدقيقة الذي تم تحقيقه من خلال الدرفلة المنضبطة وإضافات الميكروسبائك. يحتوي الفولاذ على النيوبيوم والفاناديوم والتيتانيوم لتقليل حجم الحبيبات وتقوية الترسيب، مما يؤدي إلى توازن ممتاز بين القوة والصلابة وقابلية لحام متفوقة مقارنة بالفولاذ الكربوني التقليدي.

عملية التصنيع في MetalZenith

تستخدم MetalZenith عملية تصنيع الفولاذ المتقدمة في فرن القوس الكهربائي (EAF) تليها تنقية في القادوس لتحقيق تحكم دقيق في التركيب الكيميائي. يخضع الفولاذ للدرفلة المنضبطة في مصانع الدرفلة الحديثة لدينا مع التحكم في العمليات بواسطة الكمبيوتر، مما يضمن تكييف الأوستينيت الأمثل وحركيات التحول. يتم تطبيق تقنيات التبريد المتسارع لتحقيق الخصائص الميكانيكية المطلوبة مع الحفاظ على صلابة ممتازة عند درجات حرارة منخفضة.

إجراءات المعالجة الحرارية

يتم عادةً تزويد GB Q460 في حالة الدرفلة، باستخدام معالجة حرارية ميكانيكية منضبطة (TMCP) لتحقيق الخصائص المحددة. عند الحاجة إلى التطبيع، يتم تسخين الفولاذ إلى 850-950°C تليها التبريد في الهواء. قد يتم إجراء معالجة حرارية لتخفيف الإجهاد عند 580-650°C بعد عمليات اللحام أو التشكيل. تتميز مرافق المعالجة الحرارية في MetalZenith بتحكم دقيق في درجة الحرارة وتسخين موحد لضمان نتائج متسقة.

خصائص اللحام

يظهر الفولاذ قابلية لحام ممتازة مع قيم مكافئ الكربون (CE) عادةً أقل من 0.45%، مما يقلل من خطر التشقق البارد. عادةً لا يتطلب التسخين المسبق للأقسام التي تصل سماكتها إلى 25 مم. قد تكون معالجة الحرارة بعد اللحام مفيدة للأقسام السميكة أو التطبيقات الحرجة. تشمل المواد الاستهلاكية المتوافقة مع اللحام أقطاب منخفضة الهيدروجين ومعادن تعبئة متطابقة القوة.

معايير الجودة والامتثال

تلتزم إنتاج MetalZenith من GB Q460 بدقة بمواصفات GB/T 1591 مع الامتثال الإضافي للمعايير الدولية بما في ذلك EN 10025-4 (ما يعادل S460) و ASTM A572. يشمل نظام إدارة الجودة لدينا فحص المواد الخام الواردة، ورصد العمليات، واختبار المنتج النهائي، وتوثيق شامل. تتوفر خدمات الفحص من طرف ثالث عند الطلب.

الدعم الفني وخدمات الهندسة

تقدم MetalZenith دعمًا فنيًا شاملاً بما في ذلك إرشادات اختيار المواد، وتطوير إجراءات اللحام، وتوصيات المعالجة الحرارية، وتحسين الخصائص الخاصة بالتطبيق. يقدم فريق الهندسة المعدنية لدينا استشارات حول اعتبارات التصميم وتقنيات التصنيع وتحسين الأداء لضمان نتائج ناجحة للمشاريع.

🧪 Chemical Composition

| العنصر | المحتوى (%) | الدرجة Q460C | الدرجة Q460D |

|---|---|---|---|

| الكربون (C) | ≤ 0.20 | ≤ 0.18 | ≤ 0.18 |

| المنغنيز (Mn) | 1.00-1.70 | 1.00-1.70 | 1.00-1.70 |

| السيليكون (Si) | 0.15-0.55 | 0.15-0.55 | 0.15-0.55 |

| الفوسفور (P) | ≤ 0.030 | ≤ 0.025 | ≤ 0.025 |

| الكبريت (S) | ≤ 0.030 | ≤ 0.015 | ≤ 0.010 |

| الكروم (Cr) | ≤ 0.80 | ≤ 0.80 | ≤ 0.80 |

| النيكل (Ni) | ≤ 0.80 | ≤ 0.80 | ≤ 0.80 |

| الموليبدينوم (Mo) | ≤ 0.30 | ≤ 0.30 | ≤ 0.30 |

| الفاناديوم (V) | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 |

| النيوبوم (Nb) | 0.015-0.060 | 0.015-0.060 | 0.015-0.060 |

| التيتانيوم (Ti) | 0.02-0.20 | 0.02-0.20 | 0.02-0.20 |

| الألمنيوم (Al) | ≥ 0.015 | ≥ 0.015 | ≥ 0.015 |

⚙️ Mechanical Properties

| الخاصية | السماكة (مم) | القيمة | معيار الاختبار |

|---|---|---|---|

| قوة الخضوع (ميجا باسكال) | ≤ 16 | ≥ 460 | GB/T 228.1 |

| قوة الخضوع (ميجا باسكال) | 16-40 | ≥ 440 | GB/T 228.1 |

| قوة الخضوع (ميجا باسكال) | 40-63 | ≥ 420 | GB/T 228.1 |

| قوة الشد (ميجا باسكال) | ≤ 63 | 570-720 | GB/T 228.1 |

| التمدد (%) | ≤ 63 | ≥ 17 | GB/T 228.1 |

| طاقة الصدمة (جول) | 20°C | ≥ 34 | GB/T 229 |

| طاقة الصدمة (جول) | 0°C | ≥ 34 | GB/T 229 |

| طاقة الصدمة (جول) | -20°C | ≥ 34 | GB/T 229 |

| صلابة برينيل (HB) | الجميع | 170-230 | GB/T 231.1 |

| حد التعب (ميجا باسكال) | الجميع | 240-280 | GB/T 4337 |

| معامل المرونة (جيجا باسكال) | الجميع | 206 | GB/T 22315 |

| نسبة بواسون | الجميع | 0.26-0.30 | GB/T 22315 |

🔬 Physical Properties

| الخاصية | القيمة | درجة الحرارة | الوحدات |

|---|---|---|---|

| الكثافة | 7.85 | 20°C | غ/cm³ |

| نقطة الانصهار | 1510-1540 | - | °C |

| الموصلية الحرارية | 54 | 20°C | W/m·K |

| الموصلية الحرارية | 46 | 100°C | W/m·K |

| معامل التمدد الحراري | 12.5×10-6 | 20-100°C | /K |

| معامل التمدد الحراري | 13.8×10-6 | 20-200°C | /K |

| السعة الحرارية النوعية | 500 | 20°C | J/kg·K |

| المقاومة الكهربائية | 0.16 | 20°C | µΩ·m |

| نفاذية مغناطيسية | مغناطيسي حديدي | 20°C | - |

| درجة حرارة كوري | 770 | - | °C |

| الانتشار الحراري | 13.8×10-6 | 20°C | m²/s |

| الانبعاثية | 0.85-0.95 | 600°C | - |

📏 Product Specifications

| المواصفات | الخيارات المتاحة | نطاق الحجم | المعايير |

|---|---|---|---|

| الألواح | مدرفلة على الساخن، مُعالجة حرارياً | سمك 6-100 مم | GB/T 1591، GB/T 3274 |

| الأوراق | مدرفلة على الساخن، مدرفلة على البارد | سمك 1.5-6 مم | GB/T 1591، GB/T 708 |

| الشرائط | دائري، مربع، مسطح | قطر 10-300 مم | GB/T 1591، GB/T 702 |

| المقاطع الهيكلية | شعاع H، شعاع I، قناة | حسب GB/T 11263 | GB/T 1591، GB/T 11263 |

| الأنابيب | غير ملحومة، ملحومة | 20-600 مم OD | GB/T 8162، GB/T 8163 |

| تشطيب السطح | أسود، مُخلل، مُنفجر بالرصاص | Ra 1.6-12.5 µm | GB/T 1031 |

| تحمل الأبعاد | قياسي، دقيق | ±0.1-±3.0 مم | GB/T 709، GB/T 708 |

| الطول | ثابت، عشوائي | 3-12 م قياسي | مواصفات العميل |

| حالة الحافة | حافة المصنع، حافة مقطوعة | حسب المتطلبات | GB/T 709 |

| المعالجة الحرارية | كما هو مدرفل، مُعالج حرارياً | 850-950°C | GB/T 1591 |

| الاختبار | شهادة اختبار المصنع | 3.1، 3.2 حسب EN 10204 | EN 10204، GB/T 1591 |

| التغليف | حزمة، صندوق، حاوية | معيار التصدير | متطلبات العميل |

دعونا نخلق النجاح لمشروعك

فريق محترف، منتجات متميزة، خدمة كاملة - نجاح مشروعك هو مهمتنا

Our Advantages in Processing GB Q460

المعالجة الحرارية الميكانيكية المتقدمة

MetalZenith تستخدم تقنية الدرفلة المتقدمة التي يتم التحكم فيها وأنظمة التحكم في درجة الحرارة الدقيقة لتحقيق تحسين مثالي للحبيبات وخصائص ميكانيكية في فولاذ GB Q460، مما يضمن جودة متسقة وخصائص أداء متفوقة.

أنظمة مراقبة الجودة الشاملة

يتميز مختبر الاختبار المتطور لدينا بأجهزة طيفية متقدمة، وآلات اختبار عالمية، ومعدات فحص بالموجات فوق الصوتية، مما يتيح التحقق من الجودة بنسبة 100% والامتثال لمعايير GB/T 1591 لكل دفعة إنتاج.

سلسلة التوريد العالمية والتخصيص

تقدم MetalZenith خيارات تخصيص مرنة تشمل الأبعاد المحددة، ومعالجات السطح، ومتطلبات الخصائص الميكانيكية، مدعومة بشبكة لوجستية عالمية فعالة تضمن التسليم في الوقت المناسب في جميع أنحاء العالم.

موثوق بك الفولاذ

شريك التصنيع

استفسار سريع

الصناعات التي نقدم خدماتنا لها

حلول الصلب الاحترافية عبر الصناعات الرئيسية

المؤهلات والشهادات